Sp10 assembly, installation and operation – Finish Thompson SP10 SERIES SELF-PRIMING User Manual

Page 5

5

Maximum Allowable Motor Power

• Do not exceed the maximum power rating for the pump coupling.

• Standard coupling for the SP10 is 10-pole & maximum 2 HP (1.5 kW).

Priming Liquid Volume

Initial filling (or refilling after maintenance) of the pump housing requires 0.6 US gallon / 77 oz. (2.7 liters) of liquid.

Unpacking and Inspection

Unpack the pump and examine for any signs of shipping damage. If damage is detected, save the packaging and notify the carrier

immediately.

Section I - Assembly

Tools Required:

Metric socket or wrench set, 9/16” socket or wrench, 8 mm

Allen wrench, and 3/16” Allen wrench (NEMA motors

only) and pliers (for fill/drain plugs).

Pumps with Motors

Proceed to “Installation” Section II.

Pumps Without Motors

1. Remove the pump, drive magnet assembly and hard-

ware package from the carton.

CAUTION: Keep away from metallic particles, tools

and electronics. Drive magnets MUST be free of metal

chips.

WARNING

: Keep the drive magnet away from the

open end of the motor adapter and barrier. Strong mag-

netic attraction could allow the drive hub to enter the

motor adapter resulting in injury or damage.

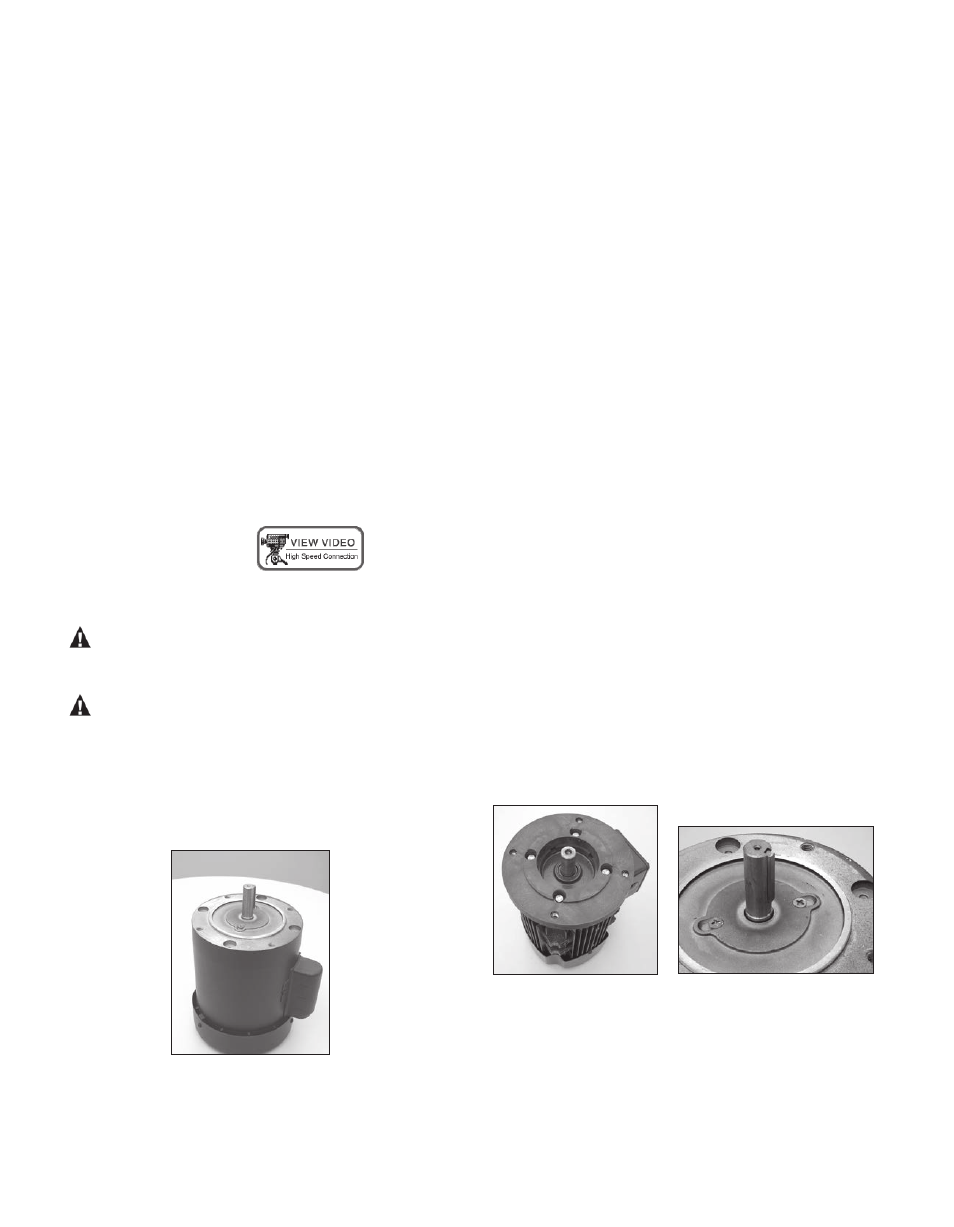

2. Place motor on the fan end. See figure 1.

NOTE: For 56C/145TC frame motors go to step 4.

Figure 1

3. For Metric motors install the motor adapter flange

(item18) on the motor face using bolts, lock washers

and flat washers (items 31,32 & 33). See figure 2.

Torque bolts to the following:

• 63 frame (M4) = 30 in-lb (3.4 N-m)

• 71 frame (M5) = 90 in-lb (10.2 N-m)

• 80 frame (M6) = 90 in-lb (10.2 N-m)

NOTE: 63/71 B14 adapter flange is reversible. Install

63/71 B14 adapter so that proper motor flange size is

facing motor.

NOTE: Apply anti-seize compound on the threads of

the bolts.

4. Coat the motor shaft with anti-seize compound. Insert

the key supplied with the motor into the keway on the

motor shaft. See figure 3.

Note: Make sure the motor shaft is clean & free of

burrs. The outer drive is precision machined and has a

bore tolerance of +.0005/-0 inch.

Figure 2

Figure 3

SP10 Assembly, Installation and Operation