Sp10 capabilities – Finish Thompson SP10 SERIES SELF-PRIMING User Manual

Page 4

4

CAUTION: Never start or operate with a closed suction valve.

WARNING

: Operation without priming or against a closed discharge valve can result in high temperatures that can

result in injury or damage to pump components.

CAUTION: Always provide adequate NPSHa (net positive suction head available). It is recommended to provide at

least 2 feet (61 cm) above the NPSHr (net positive suction head required).

CAUTION: If pump is used on variable speed drive, do not exceed 60 Hz.

SP10 Capabilities

Maximum Working Pressure: 80 psi (5.5 bar)

Maximum Temperature:

Polypropylene: 180º F (82º C); PVDF: 220º F (104º C)

NOTE: Maximum temperature is application dependent. Consult a chemical resistance guide

or the chemical manufacturer for chemical compatibility and temperature limits.

Maximum Lift:

25 feet (7.6 meters) with 4.18” and 4” diameter impellers. See the chart below for maximum lift

for other impeller diameters.

Model

3450 rpm

2900 rpm

SP10

½ gpm (1.9 lpm)

1.9 lpm (½ gpm)

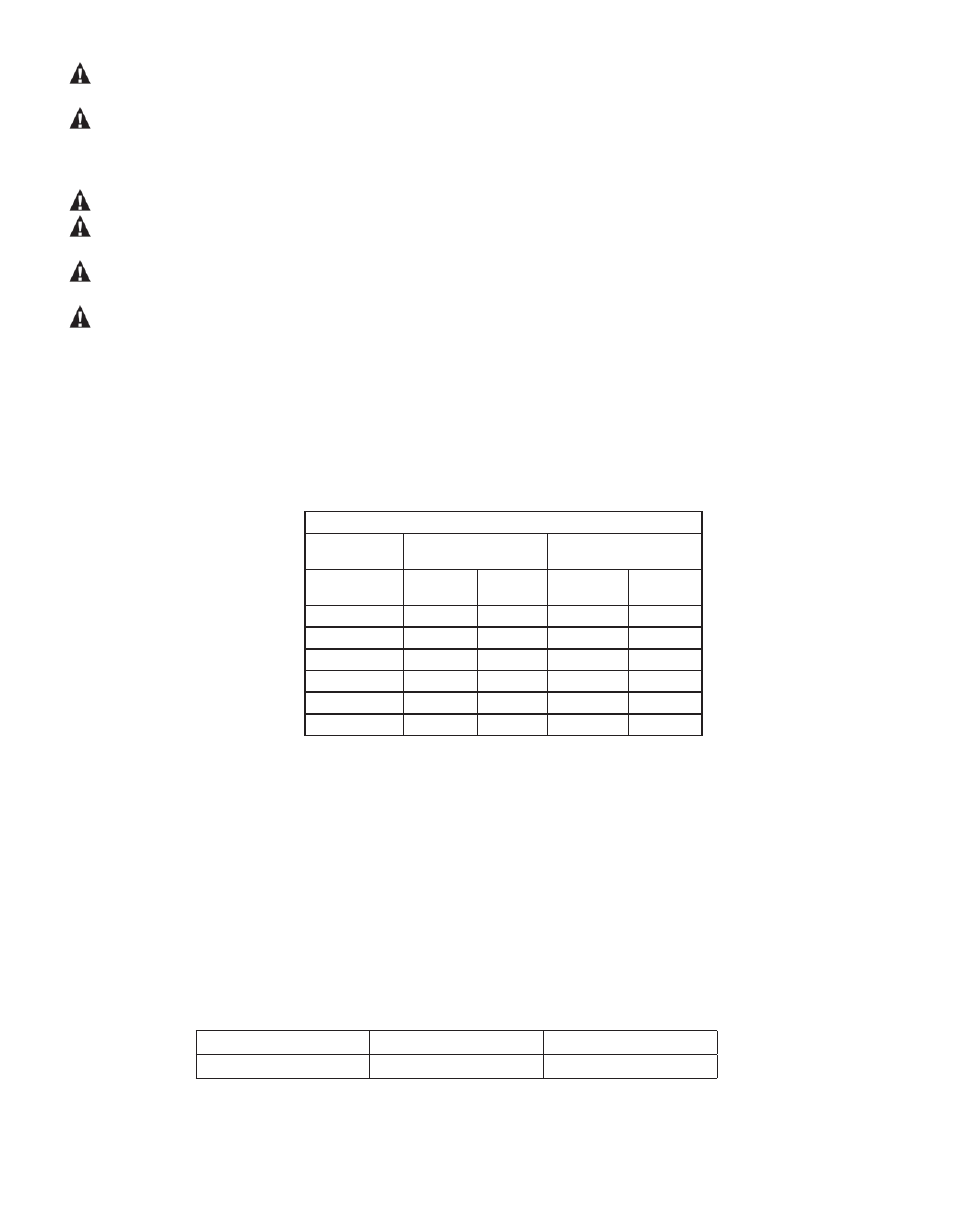

SP10 Maximum Lift Chart

1” (25.4 mm) Suction

Piping

1.5” (38.1 mm) Suction

Piping

Impeller Diameter

Max. Lift

@ 3450 rpm

Max. Lift

@ 2900 rpm

Max. Lift

@ 3450 rpm

Max. Lift

@ 2900 rpm

4.18” (106.2 mm)

25’ (7.6 M)

25’ (7.6 M)

25’ (7.6 M)

25’ (7.6 M)

4.00” (101.6 mm)

25’ (7.6 M)

25’ (7.6 M)

25’ (7.6 M)

20’ (6.1 M)

3.75” (95.3 mm)

20’ (6.1 M)

20’ (6.1 M)

20’ (6.1 M)

15’ (4.6 M)

3.5” (88.9 mm)

20’ (6.1 M)

15’ (4.6 M)

15’ (4.6 M)

10 (3.1 M)

3.25” (82.6 mm)

15’ (4.6 M)

10 (3.1 M)

15’ (4.6 M)

10 (3.1 M)

3” (76.2 mm)

10’ (3.1 M)

5’ (1.5 M)

10’ (3.1 M)

5’ (1.5 M)

NOTE: Lift was determined on fresh, cold water with 1” and 1 ½” Schedule 40 pipe. Specific

gravity affects lift capability. Divide maximum lift from chart above by the specific gravity to

determine equivalent maximum lift.

Solids: Maximum particle size is 100 microns for slurries and 1/64” (.4 mm) for infrequent particles.

Maximum hardness is 80 HS. Maximum concentration is 10% by weight. If solids are being

pumped, it is

recommended the pump has either ceramic or, for best results, silicon carbide components.

Pumping solids may lead to increased wear.

NOTE: While the pump is capable of being used in sump applications, it is NOT a trash pump. Care must be taken to ensure that debris

and foreign objects do not enter the pump or damage may result. Suggest using a 1” strainer basket with 1/32” (.8 mm) perforations

or 1 1/2” strainer basket with 1/8” (3.2 mm) perforations. Regular strainer basket maintenance is required to prevent plugging and

decrease in NPSHa so not to starve and damage the pump.

Minimum Allowable Flow Rate

Do not allow the flow rate to drop below the minimum flow rate listed in the chart below.

WARNING:

The pump and associated components are heavy. Failure to properly support the pump during lifting and

movement could result in serious injury or damage to the pump and components.

CAUTION: This pump should never be started without the 0.6 US gallon /77 oz. ( 2.7 liters) of priming fluid in the

housing. If the pump has a PTFE, ceramic or silicon carbide bushing, IT CANNOT BE RUN DRY WITHOUT CAUSING

DAMAGE TO THE PUMP. However, the pump can operate without liquid in the housing if the pump has a carbon bushing.

The exact length of time the pump can operate dry with a carbon bushing varies with operating conditions and environment.

Maximum Sound Level:

69 dBA (pump only)