Finish Thompson SP10 SERIES SELF-PRIMING User Manual

Page 11

11

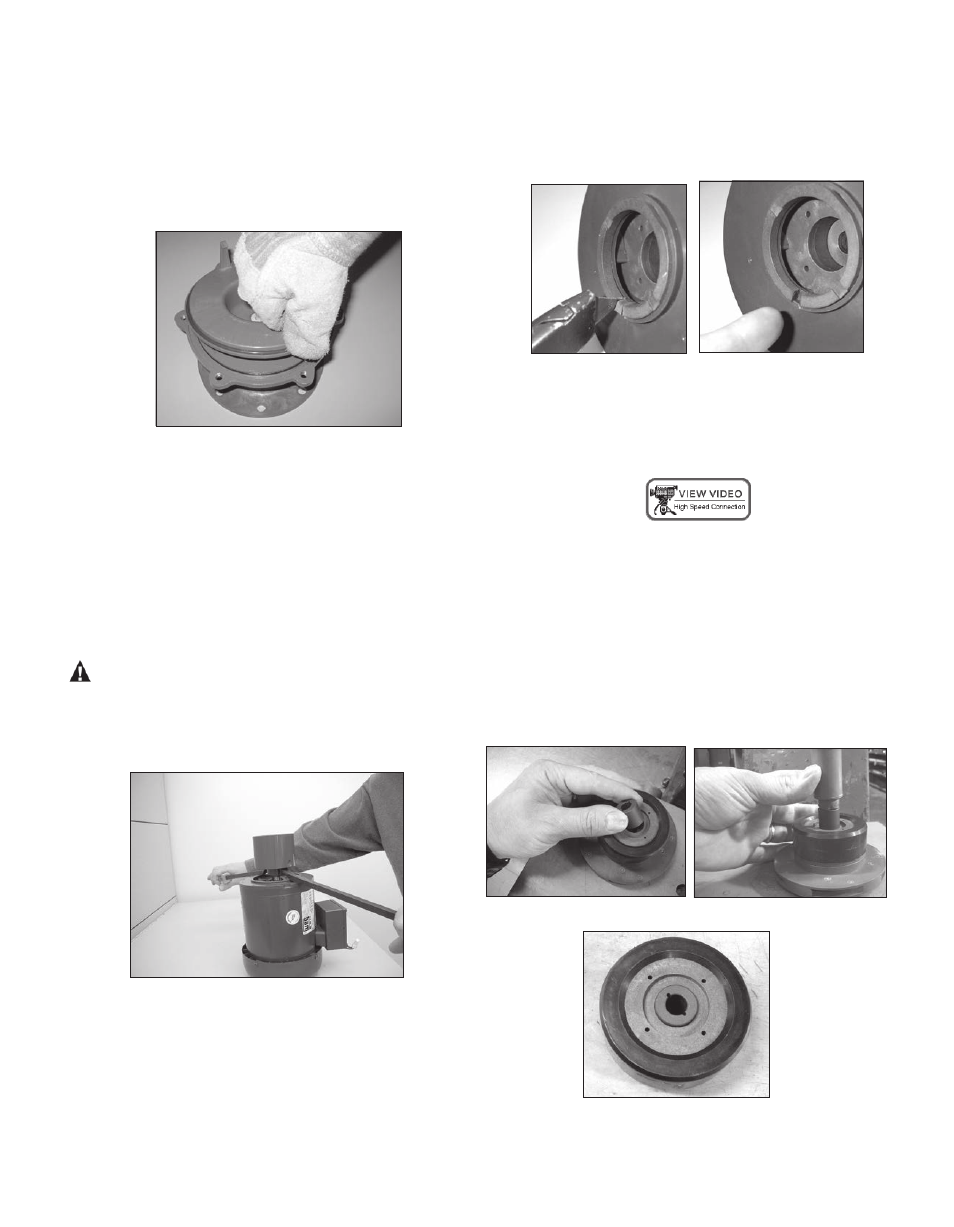

12. Pull on one of the 3 prongs to remove the barrier (item

11) from the clamp ring and motor adapter (items13 &

15). NOTE: Prongs are sharp. Use a glove or rag for

better grip. Motor adapters have an o-ring seal between

the barrier and adaptor so fit may be snug. See figure

21. Inspect the inside and outside of the barrier for

signs of rubbing.

Figure 21

13. Remove the o-ring (item 4) from the barrier and inspect

for chemical attack, swelling, brittleness, cuts, etc.

14. Visually inspect the outer drive (item 17) for rubbing,

damage, corrosion, or loose magnets.

Outer Drive Replacement

1. Remove the setscrews (item 17B) from the side of the

drive (NEMA motors) or the bolt, lock washer and flat

washer (items 25, 26 & 27) from the center of the drive

(metric motors).

WARNING: Be careful, tools will want to be attracted

to the magnets.

2. Remove the drive magnet from the motor shaft by gen-

tly prying up from the bottom of the drive. See figure 22.

3. To reinstall the drive or a new drive, follow the instruc-

Figure 22

tions from Section I – Assembly, Pumps without

Motors, Steps 4-6.

Thrust Ring Replacement

1. The thrust ring (item 8A) is held in-place with a snap fit

with a ridge. Using a razor, knife, or side cutters, cut

a notch out of the thrust ring. Pull ring up and out of

the holder. See figures 23 & 24.

2. To reinstall, align the two flats on the thrust ring with

the flats in the bore of the impeller. Using a piece of

wood, press into place using an arbor press until the

thrust ring is completely seated in the impeller.

Bushing Replacement

To remove the bushing, place the impeller/inner drive as-

sembly in an arbor press. Insert a 7/16” diameter plastic or

wood shaft through the eye of the impeller and press the

bushing out.

To replace the bushing (item 9A), place the top of the

impeller on an arbor press with the thrust ring face down.

Insert the front of the bushing (see figure 25) into the center

of the impeller/inner drive magnet assembly. Press into

place until the bushing reaches the shoulder molded into

the inner drive. See figures 26 & 27.

Figure 23

Figure 24

Figure 25

Figure 26

Figure 27