Finish Thompson SP10 SERIES SELF-PRIMING User Manual

Page 12

12

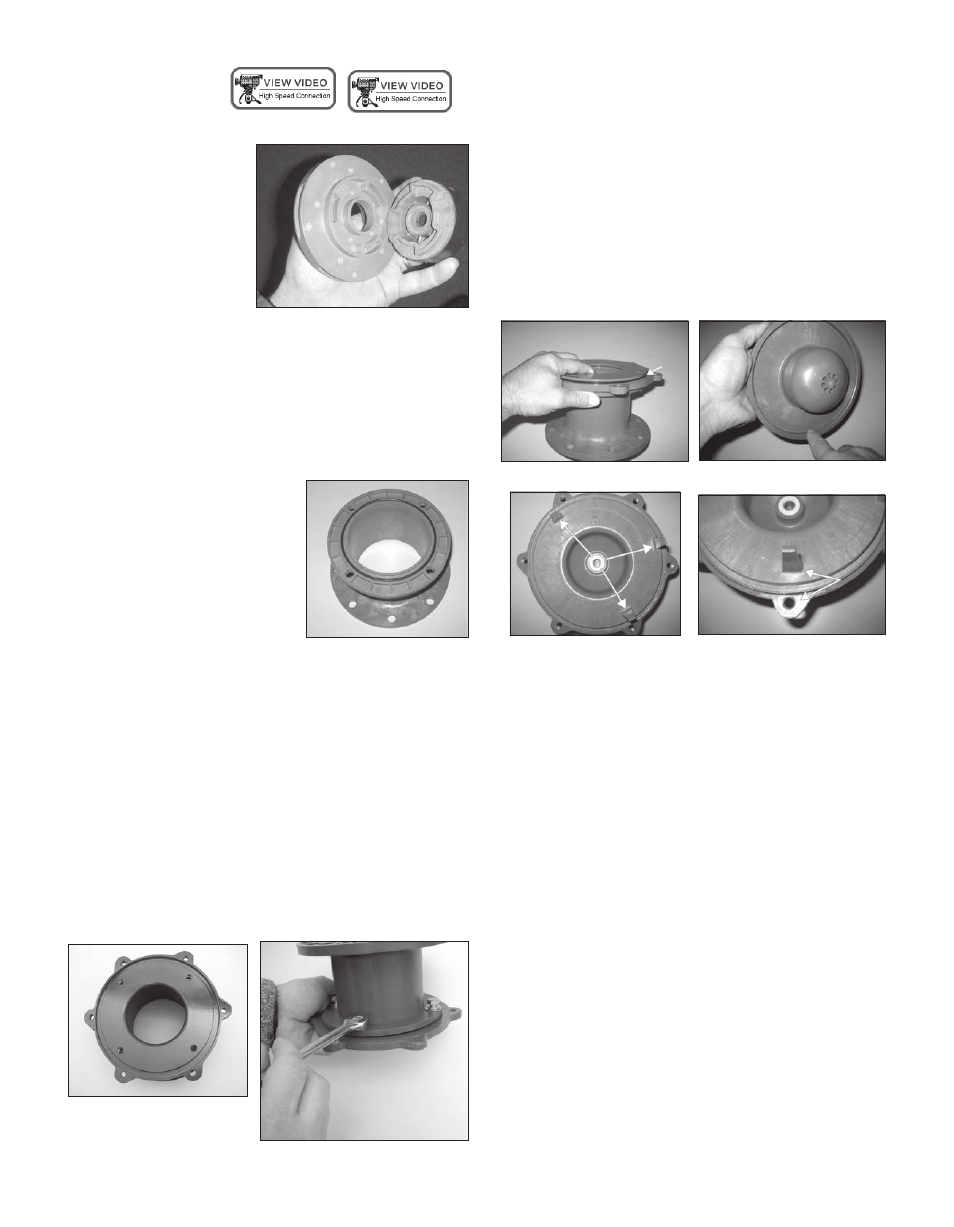

Impeller Replacement

To remove the impeller from the inner drive magnet, gently

pry off by hand or lightly

tap on the back of the im-

peller. See figure 28.

To install a new impel-

ler, place the inner drive

magnet assembly face up.

Line up the patterns on the

impeller with the ones on

the inner drive magnet so

they match and press into place by hand. An arbor press can

also be used to press the impeller on the inner drive. Place

a piece of wood over the top of the impeller thrust ring and

push down on the impeller until it is completely seated in

the inner drive.

Figure 28

Section VI Reassembly

1. Place motor adapter (item 15)

so the large flange is on the

bench. Rotate the adapter so

the four holes in the smaller

flange are in the horizontal

position. See figure 29. If re-

moved, reinstall the o-ring

(item 14) in the groove on the

face of the motor adapter.

Lubricate the o-ring with chemically compatible lubri-

cant. This will help to hold it in place. See figure 29.

Figure 29

2. Install clamp ring. Note: The discharge fitting must

be in the vertical position for all SP series pumps to

work properly – Install the clamp ring (item 13) on the

motor adapter so NO clamp ring bolt holes are in 12:00

or 6:00 position (see figure 30). Align the (4) bolt holes

with the bolt holes in the motor adapter & push straight

down. This will properly seat the o-ring to prevent

vapors from entering this area during pump operation.

3. Install (4) flat washers, lock washers and M8 bolts

(items 22, 23, 24). Tighten evenly using a star pattern.

Tighten to 60 in-lbs (6.8 N-m). See figure 31.

Figure 30

Figure 31

4. Install barrier into motor adapter/clamp ring assembly.

NOTE: If removed, reinstall the o-ring (item 12), lubri-

cate with a chemically compatible lubricant, and install

in the groove in the clamp ring before installing the

barrier. See figure 33A. Lubricate the back of the bar-

rier with a chemically compatible lubricant and push it

straight down into place. See figure 33B. Note: Barrier

can only be installed in one position. The barrier prongs

should be placed in the 11:00, 2:00 and 5:00 o’clock

positions. See figure 33 for correct orientation. Line up

the 5:00 o’clock prong with the bottom bolt hole in the

motor adapter. See figure 33C.

Figure 33A

Figure 33B

Figure 33

Figure 33C

5. Install o-ring (item 4) in groove in the barrier making

sure it is tucked in all the way around.

6. Install impeller shaft (item 10) into barrier by aligning

the flats on the shaft with the ones in the barrier. Make

sure it is completely seated.

7. Carefully install the impeller/inner drive assembly

(items 8, 8A, 9 & 9A) by sliding it over the impeller

shaft in the barrier. It is normal for the impeller/inner

drive to pop up a slight amount due to magnetic forces

with the metal clamp ring. See figures 34 & 35.