Finish Thompson DB3, 4, 5 & 5.5 Series User Manual

Page 9

wear protective clothing, eye protection and follow standard

safety procedures when handling corrosive or personally harmful

materials . Proper procedures should be followed for draining and

decontaminating the pump before disassembly and inspection of

the pump . There may be small quantities of chemicals present

during inspection .

WARNING: Magnetic force hazard . This pump should only

be disassembled and assembled using the recommended proce-

dures . The magnetic attraction is powerful enough to rapidly pull

the motor end and the wet end together . To avoid injuries, do not

place fingers between the mating surfaces of the motor and wet

end . Keep the drive magnet and impeller assembly away from

metal chips or particles .

1 . Stop the pump, lock out the motor starter, close all the

valves that are connected to the pump, and drain/decon-

taminate the pump .

WARNING: The pump must be thoroughly flushed of any

hazardous materials and all internal pressure relieved prior

to opening the pump . Allow the pump to reach ambient

temperatures prior to performing maintenance .

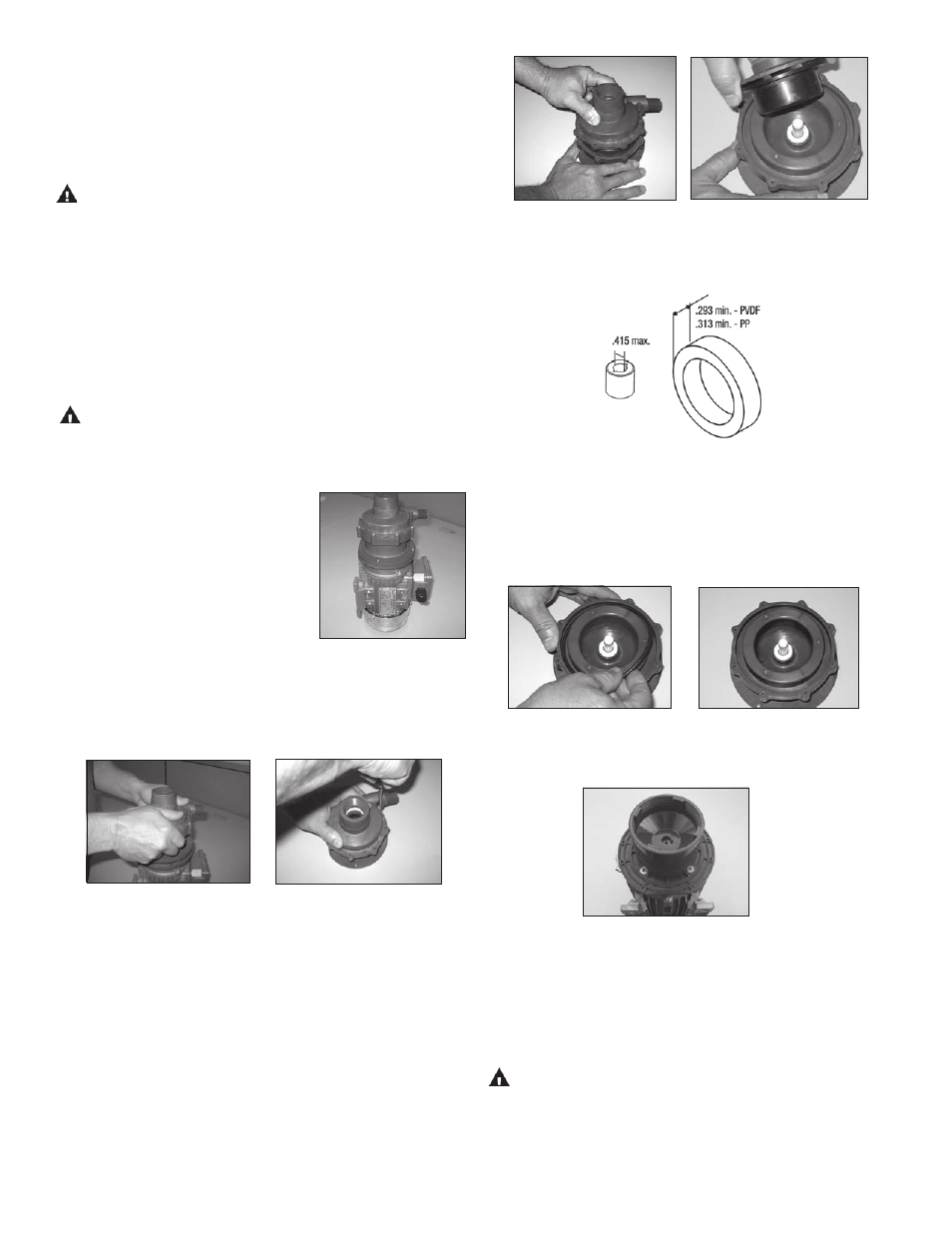

2 . Place the pump & motor vertically

on the motor fan end on a work

bench . Remove the (4) screws (item

8) securing the pump to the motor

adapter / barrier (item 4) . See

figure 13 .

Figure 13

3 . Firmly grab the pump and pull straight up to disengage the

motor and pump . See figure 14 .

4 . Place pump on bench with housing facing up . Remove (8)

housing screws (item 7) . See figure 15 .

Figure 14

Figure 15

5 . Pull housing (item 1) straight up to remove . Inspect hous-

ing for signs of wear or damage . Look for signs of rubbing or

cracked thrust ring . See figure 16 .

6 . Remove impeller assembly (item 3) . See figure 17 . Inspect

impeller and drive for signs of wear or damage . Look for

signs of rubbing, damage and wear . Check the impeller

thrust ring and bushing for wear .

NOTE: Replace the thrust washer and bushing if wear ex-

ceeds dimensions in figure 18 .

Figure 16

Figure 17

Figure 18

7 . Remove the o-ring (item 2) and look for chemical attack,

swelling, brittleness, cuts, etc . See figure 19 .

8 . Inspect the motor adapter / barrier (item 4) . Inspect the

inside and outside for signs of rubbing or damage . See

figure 20 .

Figure 19

Figure 20

9 . Visually inspect the outer drive (item 5) for rubbing, damage,

corrosion or loose magnets . See figure 21 .

Figure 21

Outer Drive Replacement

1 . Remove the bolt, lock washer and flat washer (items 9,10 &

11) from the center of the drive . Hold the drive with your

hand to prevent it from turning . See figure 22 .

WARNING: Be careful, tools may be attracted to the magnets .

2 . Remove the drive magnet from the motor shaft by gently

pushing down on 2 pry bars or large flat head screwdrivers

from the bottom of the drive . See figure 23 .

6