Finish Thompson DB3, 4, 5 & 5.5 Series User Manual

Page 7

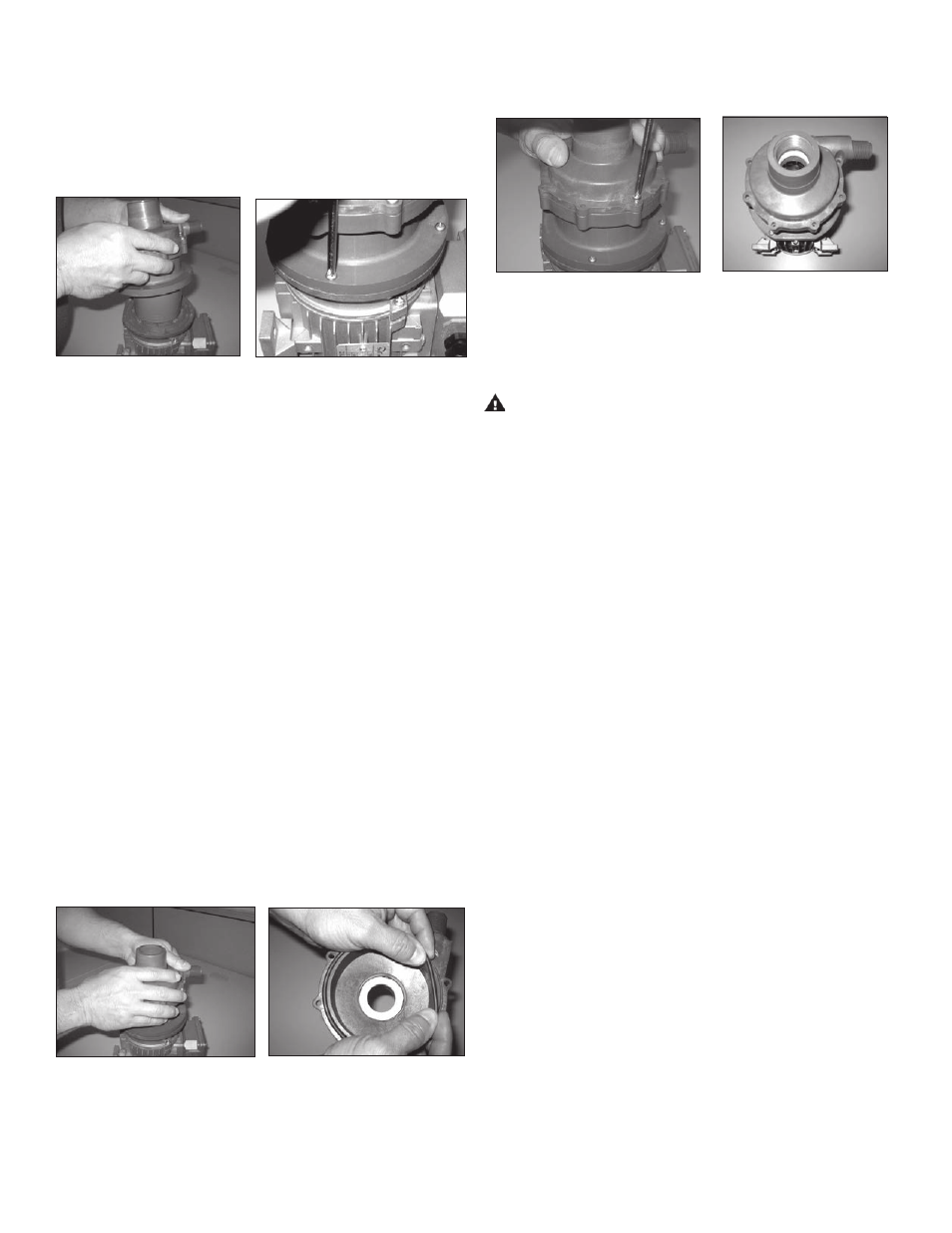

8 . Install the pump end on the motor/drive magnet assembly .

Carefully slide the pump onto the drive magnet assembly .

See figure 7 .

9 . Secure the pump to the motor adapter flange (item 6) with

(4) motor adapter screws (item 8) . Hand tighten screws be-

ing careful not to over tighten . See figure 8 .

Figure 7

Figure 8

10 . Rotate the motor fan or turn the impeller to ensure that there

is no binding in the pump .

11 . Proceed to Installation Section .

Section II – Installation

Mounting

Motor feet should be securely fastened to a solid foundation .

Instructions for horizontal discharge installation:

Note: The pump ships from the factory so the discharge will be

in a vertical orientation . These instructions allow a horizontal

discharge .

1 . Place the pump & motor in an upright position on the fan end

of the motor . Remove (8) housing screws (item 7) . Pull the

housing away from the motor adapter / barrier (item 4) and

remove the o-ring (item 2) . Reinstall the housing in the 3:00

position looking from the pump side . Note: O-ring will be

lubricated from the factory and should not require additional

lubrication . See figure 9 .

2 . Reinstall the o-ring onto the housing (item 1) . If o-ring will

not stay in place it may be necessary to roll the o-ring under

when installing it on the housing . See figure 10 .

Figure 9

Figure 10

3 . Align the holes in the housing with the motor adapter /

barrier . Push the housing with o-ring in place straight down

to seat the o-ring . Hold the housing in place and reinstall the

(8) housing screws (items 7, 7A) in a star like pattern using

Figure 11

Figure 12

Piping

CAUTION: The NPSH available must be greater than the

NPSH required . Filters, strainers and any other fittings in the

suction line will lower the NPSH available and should be

calculated into the application .

• Install the pump as close to the suction source as possible .

• Support the piping independently near the pump to eliminate

any strain on the pump casing . In addition, the piping should

be aligned to avoid placing stress on the pump casing .

• The suction side of the pump should be as straight and short

as possible to minimize pipe friction .

• Keep bends and valves at least ten pipe diameters away

from the suction and discharge .

• The suction line should be at least as large as the suction

inlet port or one pipe size larger so that it does not affect the

NPSHa . Do not reduce the suction line size .

• The suction line should not have any high spots . This can

create air pockets . The suction piping should be level or

slope slightly upward to the pump .

• A check valve and control valve (if used) should be installed

on the discharge line . The control valve is used for regulating

flow . An isolation valves on both the suction and discharge

is used to make the pump accessible for maintenance . The

check valve helps protect the pump against damage from

water hammer . This is particularly important when the static

discharge head is high .

• If flexible hose is preferred, use a reinforced hose rated for

the proper temperature, pressure and is chemically resistant

against the fluid being pumped .

• The suction valve must be completely open to avoid restrict-

ing the suction flow .

• It is advisable to install a flush system in the piping to allow

the pump to be flushed before the pump is removed from

service .

4

the Phillips-head screwdriver . Hand tighten screws being

careful not to over tighten . See figures 11 & 12 .

NOTE: Install two long screws (item 7A) inserting one on

either side of the discharge nozzle . See figure 12 .