Finish Thompson DB3, 4, 5 & 5.5 Series User Manual

Page 6

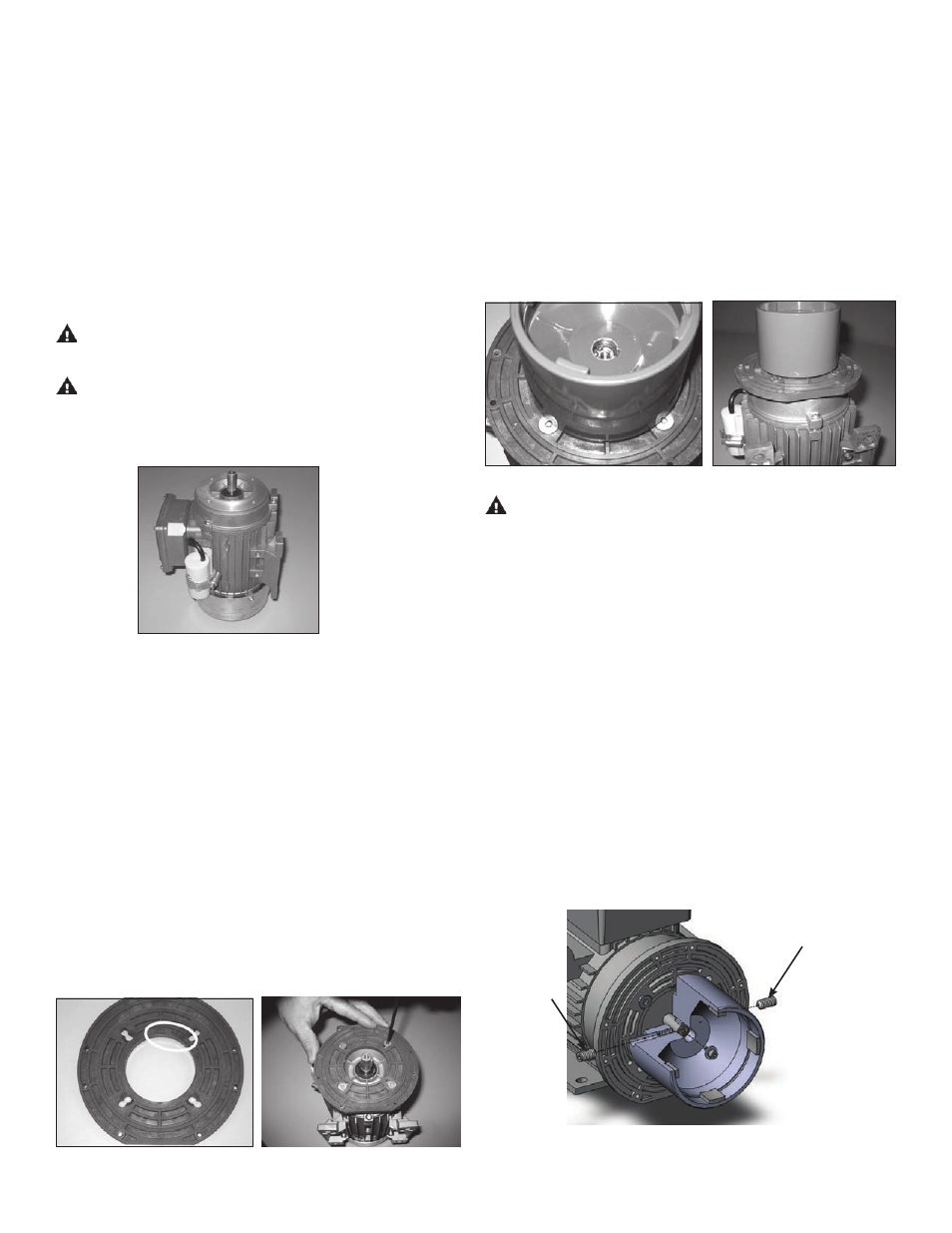

Section I - Assembly

Pumps with Motors

Proceed to Installation Section

Pumps Without Motors

Tools Required: Metric socket set, 7 mm socket (63 frame), 8 mm

socket (71 frame), 2 .5 mm (56 frame), 3 mm and 4 mm Allen

wrenches, and Phillips-head screwdriver .

1 . Remove the pump, drive magnet assembly and hardware

package from the carton .

CAUTION: Keep away from metallic particles, tools and

electronics . Drive magnets MUST be free of metal chips .

WARNING: Keep the drive magnet away from the open end

of the motor adapter and barrier . Strong magnetic attraction

could allow the drive hub to enter the motor adapter result-

ing in injury or damage .

Figure 1

3 . Install the motor adapter flange (item 6) on the motor face

using motor adapter flange bolts (item 12) .

NOTE: Apply anti-seize compound on the threads of the

bolts . Hand tighten bolts being careful not to over tighten .

See figure 3 .

2 . Place motor on the fan end . See figure 1 .

NOTE: The DB3, 4 & 5 pumps mount to either IEC

Figure 2

56, 63, 71 B14 frame motors depending on which

motor adapter is ordered . The motor adapter flange

(item 6) can be used for either frame depending on

which side is used . See stamped identification on

the flange . See figure 2 . DB5 .5 pumps mount to IEC

63 and 71 frame motors .

4 . Make sure the motor shaft is clean and free of burrs . Coat

the motor shaft with anti-seize compound . If not installed

insert key supplied with motor into keyway on motor shaft .

NOTE: The outer drive is precision machined and has a bore

tolerance of +0 .001/-0 inch . It may be necessary to tap the

drive on with a soft mallet .

5 . Slide the outer drive magnet assembly (item 5) onto the mo-

tor shaft until the motor shaft contacts the snap ring in the

bore of the drive . Turn the drive by hand to make sure it

rotates freely . See figures 4 & 5 .

Figure 4

Figure 5

WARNING: Be careful, magnets will try to attract tools .

6 . Secure the drive on the motor shaft using bolt, lock washer

and flat washer (items 9, 10, 11) . Coat the bolt threads with

anti-seize compound . Thread the bolt into the end of the mo-

tor shaft (while holding the outer drive to prevent it from

turning) . See figure 6 .

Tighten the bolt using the 2 .5 mm allen wrench (56 frame),

7mm socket (63 frame) or 8 mm socket (71 frame) to the

following torque rating:

• 56 frame (M3) = 8 in-lbs ( .9 N-m)

• 63 frame (M4) = 15 in-lbs (1 .7 N-m)

• 71 frame (M5) = 30 in-lbs (3 .4 N-m)

Figure 6

3

Figure 3

7 . Tighten two set screws (item 5B) to a torque of 75 in .-lbs .

(8 .5 N-m) using a 1/8” Allen wrench . See figure 6 .