Encoder cable installation, 16 wiring – Electro Cam 5000 Series User Manual

Page 28

3-16 Wiring

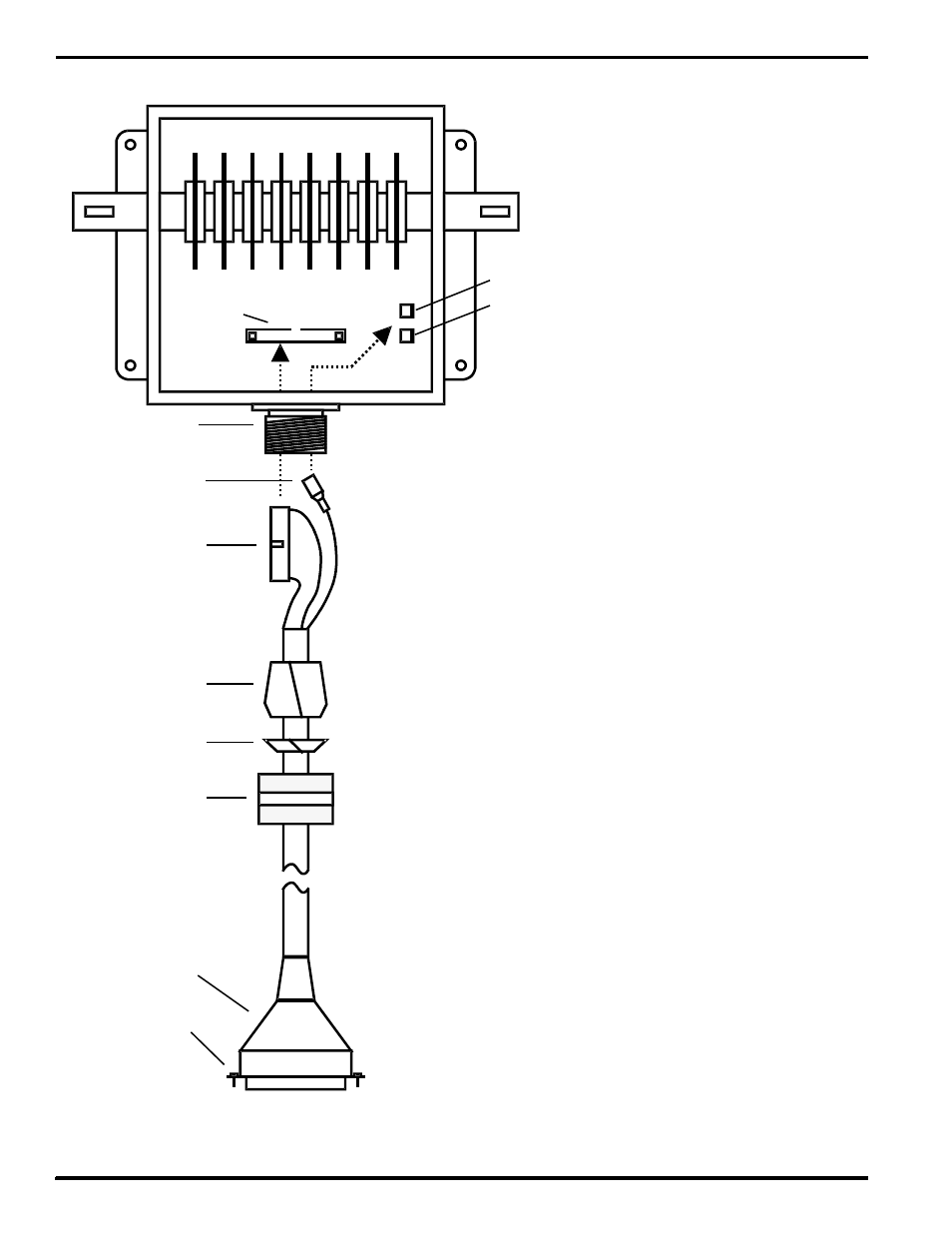

Plug shield spade connector onto

NON-TERM lug if encoder is grounded

to the machine

Plug shield spade connector onto

TERM lug if encoder is not grounded to

the machine

NON-TERM

TERM

Encoder cable receptacle (male)

connectors are keyed to plug in

one way only

Connector for

encoder (female)

Turn it parallel to the

cable as shown to

slide it through the

encoder fitting

Encoder compression

seal fitting

Spade connector for

cable shield

Split rubber sealing

grommet

Split nylon washer

Knurled compression

nut (threaded end

toward encoder)

25 pin DB connector

(female)

Retainer screws must

be securely tightened

to insure proper

cable grounding

Note: The encoder cable can be pulled through 3/4" or

larger conduit. Pull the cable from the controller to the

encoder. Turn the encoder connector (rectangular) parallel

to the cable (as pictured to the left) and tape it in this position

while it is being pulled. Pull the connector through conduit

before following the cable installation steps below.

A bulkhead connector assembly (PS-4300-09-XXX) is

available for installations where it is desirable to unplug the

encoder cable from the control enclosure.

Installation Procedure

1. Turn encoder connector (rectangular) parallel to cable

and slide knurled compression nut over it. Threaded end

of nut must face encoder connector.

2. Slip the nylon friction washer and the rubber sealing

grommet onto the cable by opening up the splits.

3. Turn encoder connector parallel to the cable and slide it

through the encoder compression seal fitting.

4. Plug encoder connector into the receptacle, making sure

that raised key on connector mates with the key slot in

the receptacle.

5. Plug the shield spade connector onto the “NON-TERM”

spade lug if the encoder is grounded to the machine, or

onto the “TERM” lug if the encoder is not grounded.

6. Slide the rubber grommet, nylon washer, and

compression nut up to the compression fitting. Thread

on the compression nut. Push a small amount of cable

into the encoder to insure that it isn’t pulling on the

connector as the compression nut is tightened.

7. Put lid back on encoder. Operating without the lid can

allow dust and other contamination to affect proper

operation of the encoder.

Encoder Cable Installation