Model 2230r, process hydrogen analyzer – Teledyne 2230R - Process Hydrogen Analyzer User Manual

Page 21

MODEL 2230R, Process Hydrogen Analyzer

Page 21

5.4 VERIFICATION

Verification Interval

Verification is a process to compare the sensor output to a known hydrogen concentration.

Verifications do not cause any wear on the sensor and can be accomplished as often as desired.

The recommended interval to perform Verification depends solely on the user’s desired

tolerance for the specific application in question. If the user does not have a specific desired

tolerance, TELEDYNE ANALYTICAL INSTRUMENTS recommends that Verification be performed

every three months.

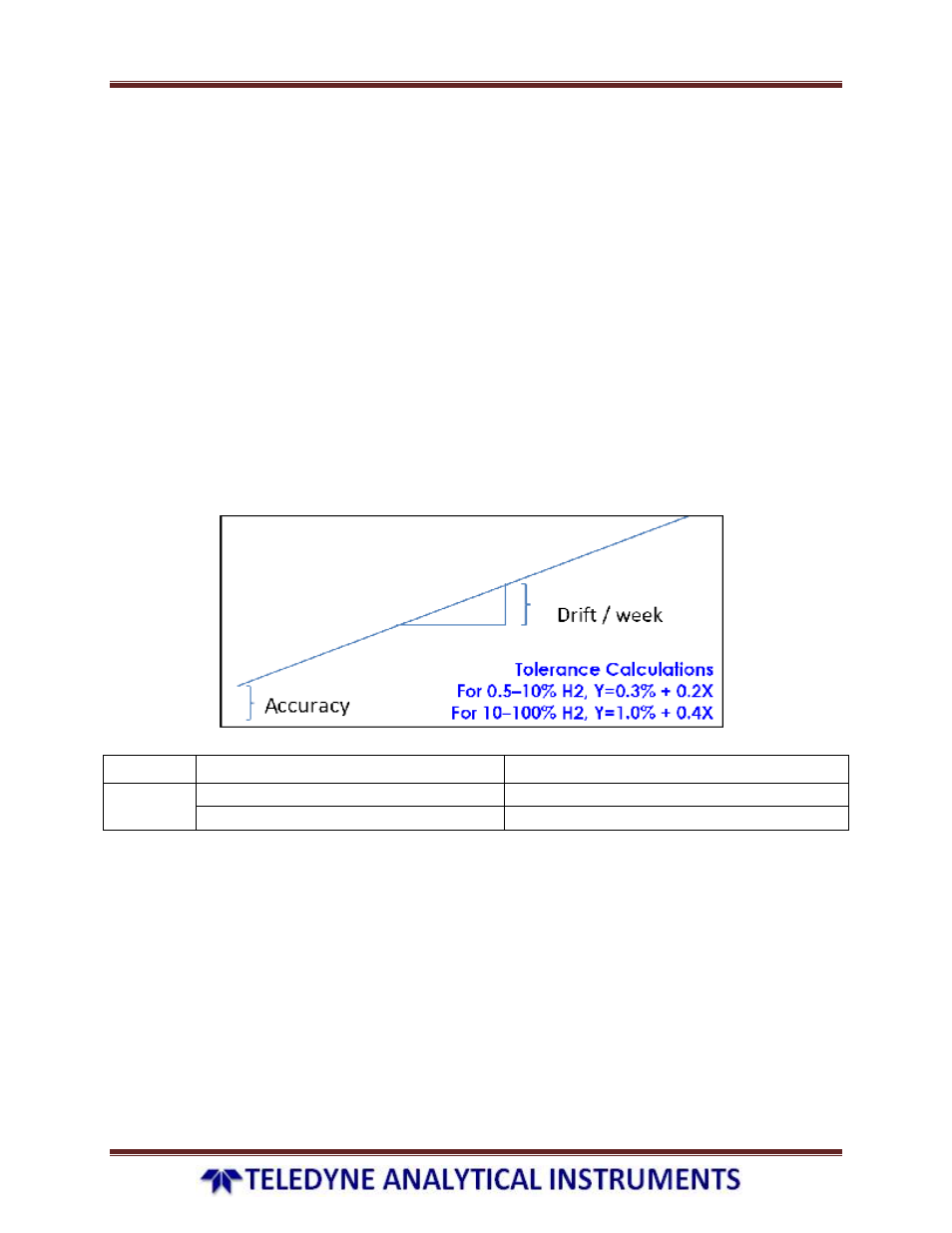

The tolerance (error) in measuring hydrogen has two primary components: the initial accuracy

number (offset) and a weekly drift value (slope). The chart below is provided as a guideline for

tolerance estimation for the Model 2230R and can be a useful tool in determining the initial

verification frequency. The subsequent verification frequencies can be decided based on the

actual weekly drift observed. The tolerance chart may be used in accordance with TELEDYNE

ANALYTICAL INSTRUMENTS Model 2230R accuracy specifications.

Tolerance Chart (Gas Temperature <65°c)

Number of Weeks after Field Calibration, X

Model

Accuracy(*):

Drift/week:

2230R

± 0.3% absolute for 0.5 to 10% H₂

± 0.2% absolute for 0.5 to 10% H₂

± 1.0% absolute for 10 to 100% H₂

± 0.4% absolute for 10 to 100% H₂

*

Sensor performance specifications are only valid for units configured for a maximum 65

°

C dry

process stream temperature. All figures assume pressure compensation, operating in ambient

that do not contain Oxygen and are in addition to any errors in the gasses used. The accuracy is

specified for serial port output only.

The drift chart can be used to determine the maximum recommended Verification interval to

maintain a required level of accuracy. For instance, if ± 1% accuracy in a 5% H2/N2 gas is

needed; Verification should be typically performed every 3.5 weeks. If ± 2% accuracy is needed

in the same gas, the recommended Verification interval can be extended to 8.5 weeks.

Verifications may be done more frequently than these intervals if desired and should always be

performed if the sensor readings are unusual or suspected to have large errors.