Model 2230r, process hydrogen analyzer, Step description 1 – Teledyne 2230R - Process Hydrogen Analyzer User Manual

Page 11

MODEL 2230R, Process Hydrogen Analyzer

Page 11

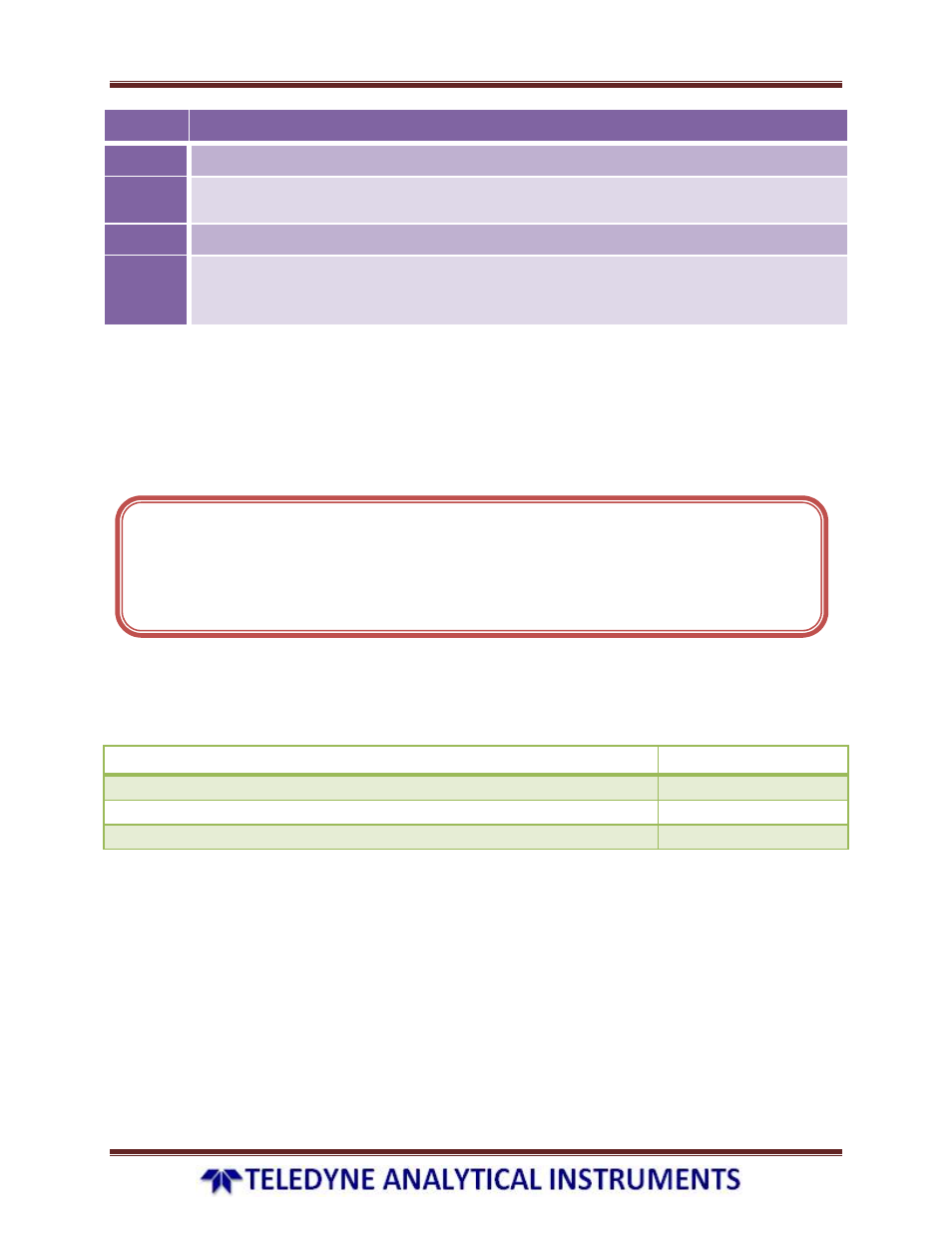

Step

Description

1

Power units on in 5% H₂/N₂ by volume or greater

2

Operate the Model 2230R Analyzer in the 5% H₂/N₂ or greater gas for six hours or

longer

3

Check to see if the sensor readings were accurate and stable over that time

4

If the readings are not accurate and stable, condition the sensor in 5% H₂/N₂ or

greater gas overnight and perform the Verification and Calibration described later

in this manual.

3.5 SETTINGS

The unit’s operational and output settings have been configured at the manufacturer with

settings specified at the time of purchase. Settings may be changed through the use of Serial

Communication as described in section 4, or through the use of an Optional User Interface

Module.

3.6 VISUAL STATUS INDICATOR

Located on the front of the unit next to model number marking, the Status Indicator LED

displays basic unit function as described below.

Status

Indicator Color

Normal operation / Hydrogen Detected below R1 set point

GREEN

Warm-up / Hydrogen Detected above R1 and below R2 set points

AMBER

Hydrogen Detected above R2 set point/ Unit fault detected

RED

3.7 OPTIMUM UNIT PERFORMANCE

For maximizing the performance of the sensor, the following steps are recommended.

•

Verify that all electrical connections and made as recommended. Switching the polarity can

cause damage to the unit. Ensure that the DC power supply utilized is appropriate and does

not have large peak-to-peak noise.

•

Perform a Field Calibration after installation and conditioning steps described in the Start-

up section are completed.

WARNING:

IF SETTINGS ARE CHANGED FROM THOSE SET BY THE

MANUFACTURER THEN IT IS THE USER’S RESPONSIBILITY TO

UNDERSTAND THE IMPLICATIONS TO THE CONNECTING EQUIPMENT

MONITORING THE UNIT.