Dings Dynamics Group 60 Series Coupler NEMA 4 User Manual

Page 9

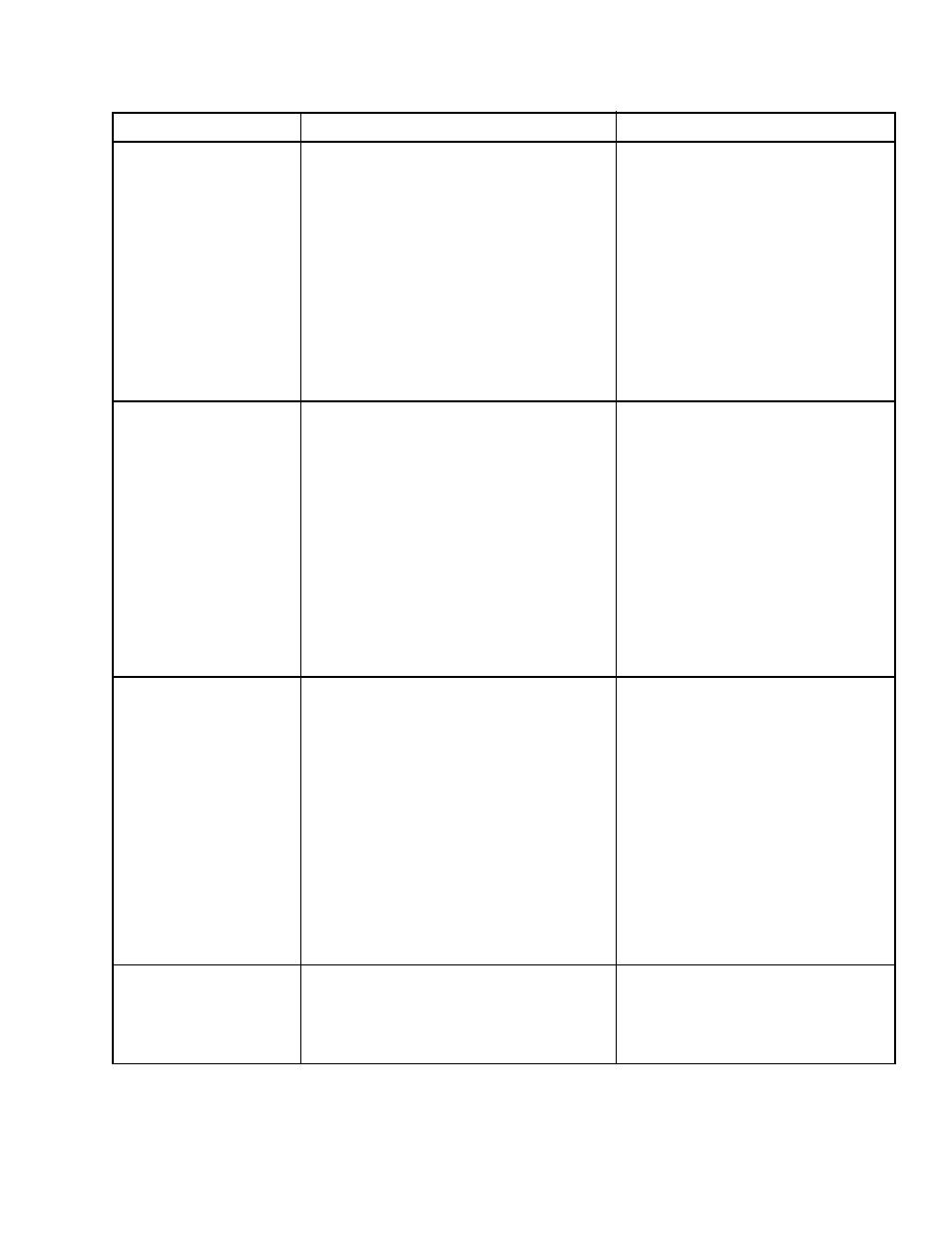

SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Brake does not release

1. Broken or damaged parts

1.

Replace.

2. Wrong voltage

2.

Check for correct voltage. Voltage

must correspond to that listed on

brake nameplate. If the voltage is

more than10% below the nameplate

voltage, the magnet may not pull in.

3. Burned out coil

3.

Replace magnet assembly (25A).

4. Incorrect wiring connections or broken

4.

Find the connection or wiring fault.

wires

Correct or repair as required.

Brake does not stop

1. Broken or damaged parts

1.

Replace.

properly

2. Worn friction disc

2.

Replace disc if worn to 1/8”

thickness. If disc replacement is not

required, adjust air gap. (Refer to

“Wear Adjustment” section.)

3. Hub positioned incorrectly

3.

Locate hub (22) and key (33), if

(models with two-piece shaft and hub

required. (Refer to “Installation”

only)

section.)

4. Brake is manually released

4.

Determine if manual release is in

normal position.

Brake chatters or hums

1. Dirty magnet faces

1.

To remove dirt, insert a clean sheet

of paper between faces and energize

brake. Move paper around between

faces to dislodge dirt, then remove

paper.

2. Magnet faces are not parallel in closed

2.

See “Pivot Stud Adjustment”

position

section.

3. Loose or broken shading coil

3.

Replace magnet assembly (25A).

4. Wrong voltage supply

4.

Check for low voltage.

Manual release does not

1. Broken or damaged parts

1.

Replace

work

2. Improper setting

2.

See “Manual Release Adjustment”

section.

9