Vertical mounting, Friction disc replacement – Dings Dynamics Group 60 Series End Mount NEMA 4X STAINLESS STEEL User Manual

Page 9

9

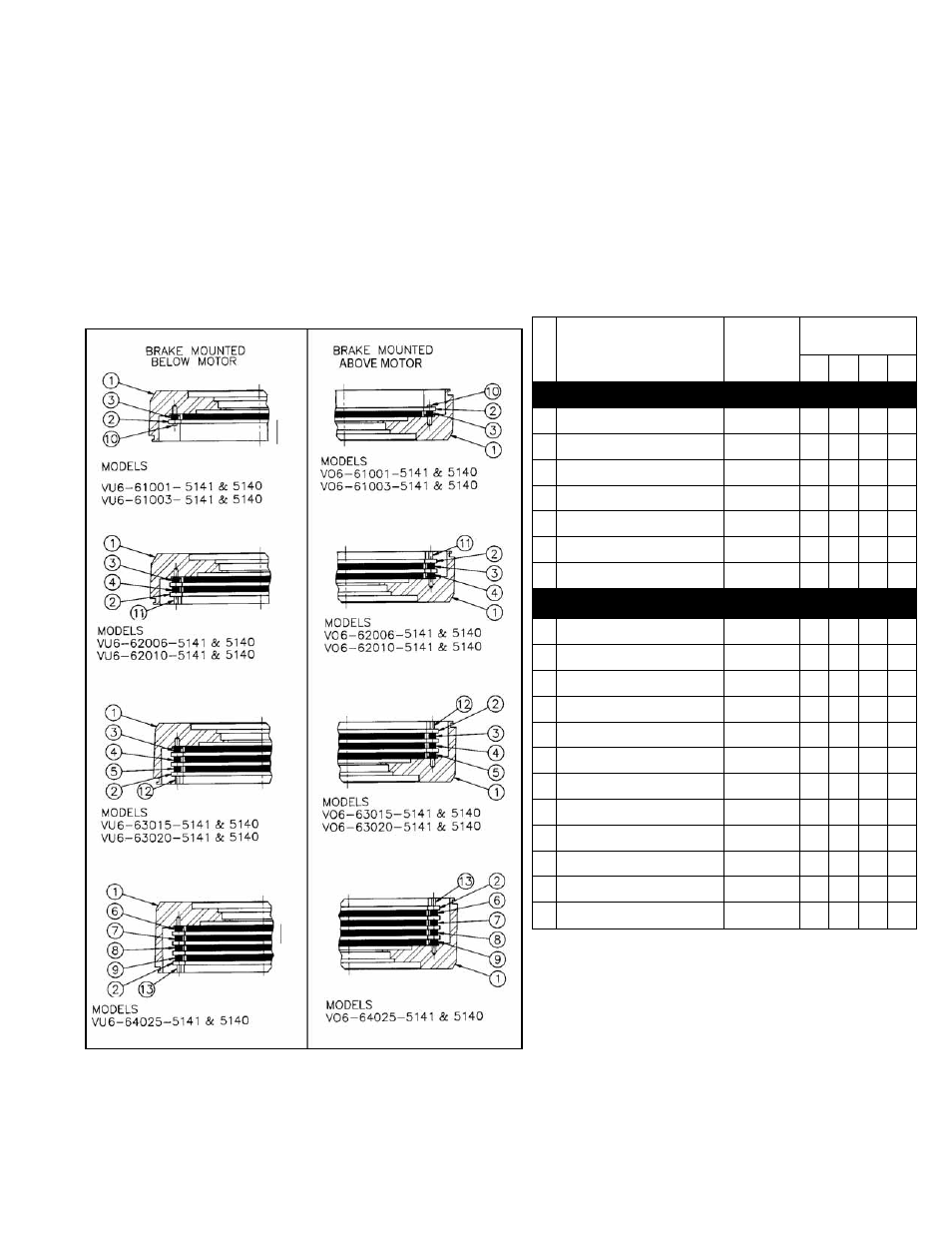

VERTICAL MOUNTING

Installation and adjustment of the vertically mounted brake is the same as on the standard model.

Friction Disc Replacement

When replacing friction discs, follow procedure outlined on page 5 with this addition:

Care must be taken to insure proper insertion of disc separating springs. Springs are color coded for easy identification, and

reference is made to spring color (see Table 1 and Figure 9). Since the installation order of the disc springs is dependent on

brake mounting position (VO= vertical over or above motor; VU= vertical under or below motor), it is important to consult the

correct diagram for spring location.

Table 1 Parts for Vertical Mounting

Figure 9

Item

No.

Description

Part No.

Qty. of Parts

(No. of rotating discs)

1

2

3

4

1 Bracket, 1 & 2 disc models, VO

L060383-011

1

1

1 Bracket, 3 disc model, VO

L060383-012

1

1 Bracket, 4 disc model, VO

L060383-013

1

1 Bracket, 1 & 2 disc models, VU

L060383-021

1

1

1 Bracket, 3 disc model, VU

L060383-022

1

1 Bracket, 4 disc model, VU

L060383-023

1

-

Cover with drain, VU (not shown)

K060589-011

1

1

1

1

2 Stationary disc, vertical mounting

H060203-004

1

2

3

4

3 Compression spring (silver)

G060350-001

2

2

2

4 Compression spring (black)

G060350-002

2

2

5 Compression spring (bronze)

G060350-003

2

6 Flotation spring (silver)

G060736-001

2

7 Flotation spring (black)

G060736-002

2

8 Flotation spring (bronze)

G060736-003

2

9 Flotation spring (red)

G060736-004

2

10 Roll pin, 1/8” dia. x 5/8” lg.

W005003-071

2

11 Roll pin, 1/8” dia. x 1” lg.

W005003-077

2

12 Roll pin, 1/8” dia. x 1-3/8” lg.

W005003-080

2

13 Roll pin, 1/8” dia. x 1-3/4” lg.

W005003-083

2