Operation, Manual release – Dings Dynamics Group 60 Series End Mount NEMA 4X STAINLESS STEEL User Manual

Page 4

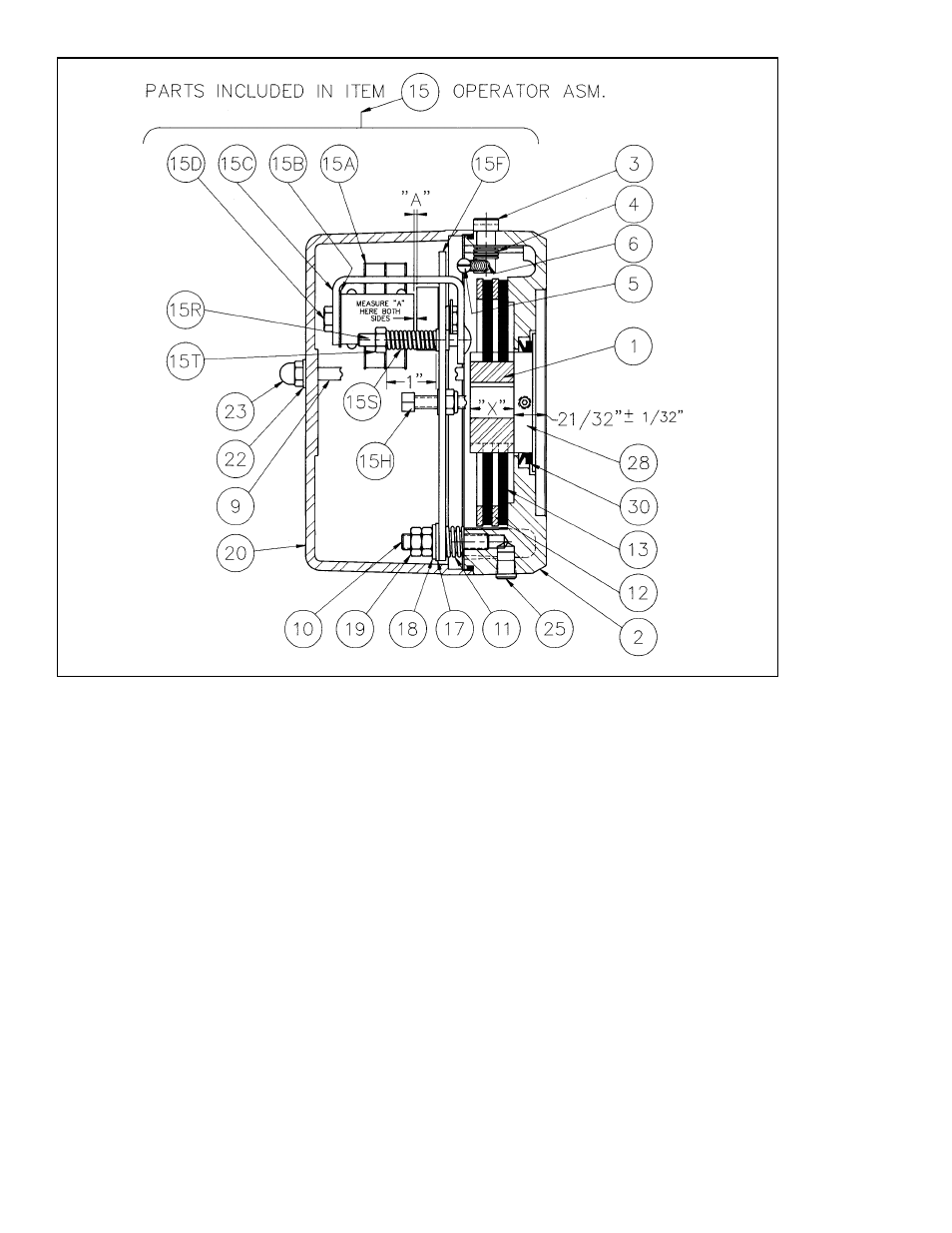

Figure 4

4

OPERATION

These brakes are spring set devices with an electrical

(magnet) release. They contain a rotating friction disc

which is driven by a hub mounted on the motor shaft. When

energized, the magnet compresses the torque springs,

removing the force pressing the stationary disc and friction

disc together. This permits free rotation of the shaft.

WARNING: Observe proper safety precautions in

applications where a brake failure would allow the load

to move in such a manner as to injure personnel. KEEP

PERSONNEL AWAY FROM LOAD AREAS.

If brake torque rating is higher than motor full-load torque

rating, use brake rating rather than motor rating when

selecting other drive components.

Take the following precautions when operating the brake:

1. Do not operate the brake at higher than normal static

torque capacity.

2. For applications with high inertia-type loads or rapid

cycling, the thermal capacity of the brake must be

considered.

3. High start-stop rates may damage motor. Consult

motor manufacturer if high cycling rates are

expected.

4. Be sure power supply conforms to electrical rating of

brake.

Manual Release

The brake is equipped with a manual release. Turn the

release knob (3) clockwise to stop position to release the

brake. The brake will remain released until the release knob

is turned counterclockwise (approx. 65

o

) or until the brake

coil is energized, automatically resetting the brake.