Dings Dynamics Group 60 Series End Mount NEMA 2 User Manual

Page 4

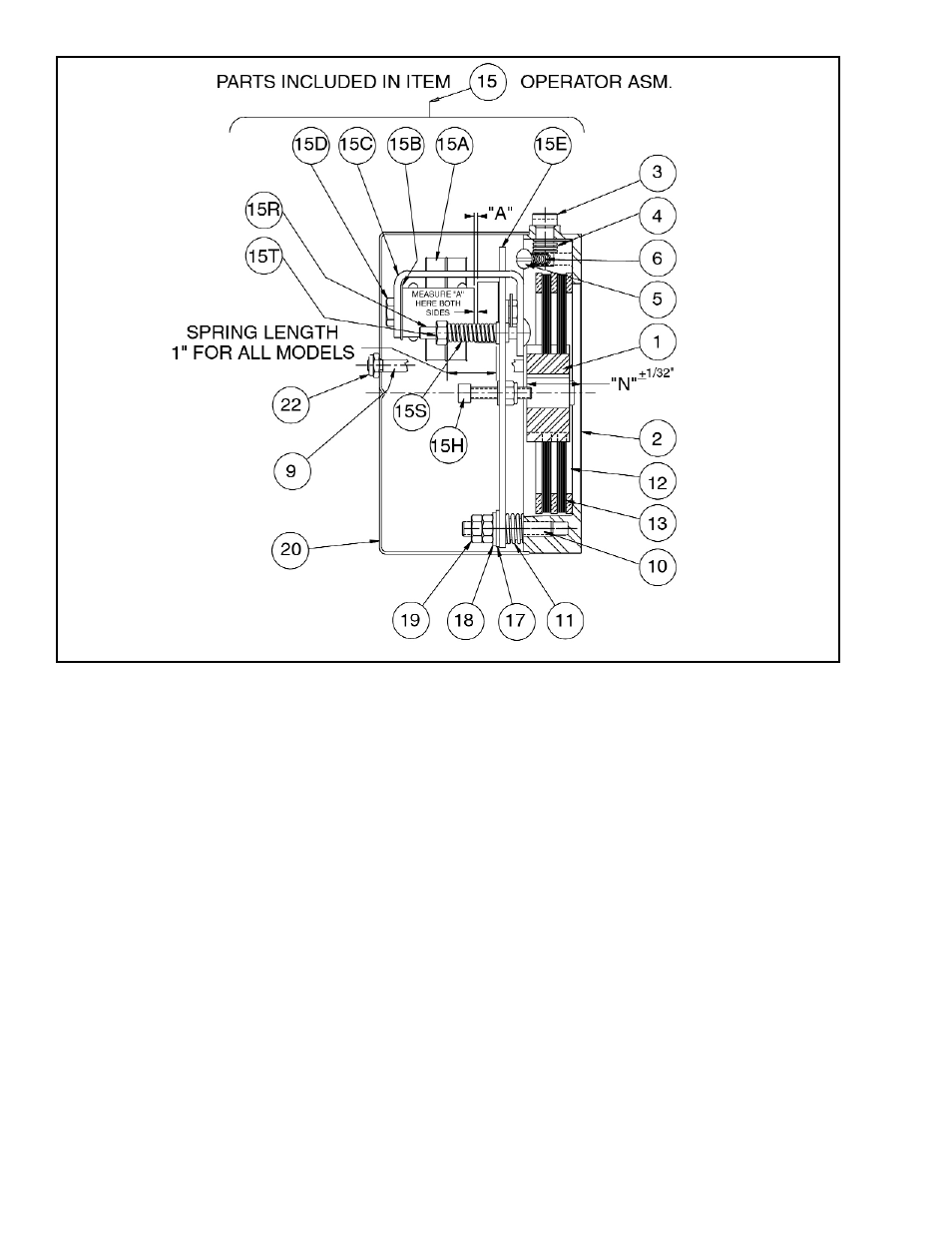

Figure 3

MAINTENANCE

CAUTION: Before attempting to service or remove

any components, make certain that the power is

disconnected and that the load is completely removed,

secured or blocked to prevent injury or property

damage.

Wear Adjustment

CAUTION: Load to be removed or blocked. Brake may

be inoperative during this procedure.

Before air gap “A” reaches .100”, adjustment is required. Any

delay in adjusting the magnet air gap will result in eventual

loss of torque. Refer to Fig. 3.

1. To adjust, remove cover locknuts (22) and cover (20)

to expose square head wear adjusting screws (15H)

and expose magnet air gap “A”.

2. Measure air gap “A” using 3/8” to 1/2” wide feeler

gauge. (Measure at center of magnet.)

3. Turn two square head adjusting screws (15H) until

air gap “A” measures:

.045/.050 for 1 disc models

.050/.055 for 2 disc models

.060/.065 for 3 disc models

.060/.065 for 4 disc models

Air gap should be the same on both sides.

4