5hfwli\lqj idxowv, Dxow 3rvvleoh fdxvh 5hfwlilfdwlrq – Diamond Products SB User Manual

Page 39

SB Wire Sawing System

Rectifying faults

SB_0107_e.mif

Page 39

5HFWLI\LQJ IDXOWV

Proceed systematically when searching for the

cause of a fault. Also you should use the

operating instructions for the drive unit being

used. If you cannot find the fault or rectify the

problem just call our Customer Services.

Before calling us however please note the

following points:

- We can help you better the more precisely you can

describe the fault

- Keep the operating instructions to hand

Before rectifying the fault discon-

nect the SB from the mains!

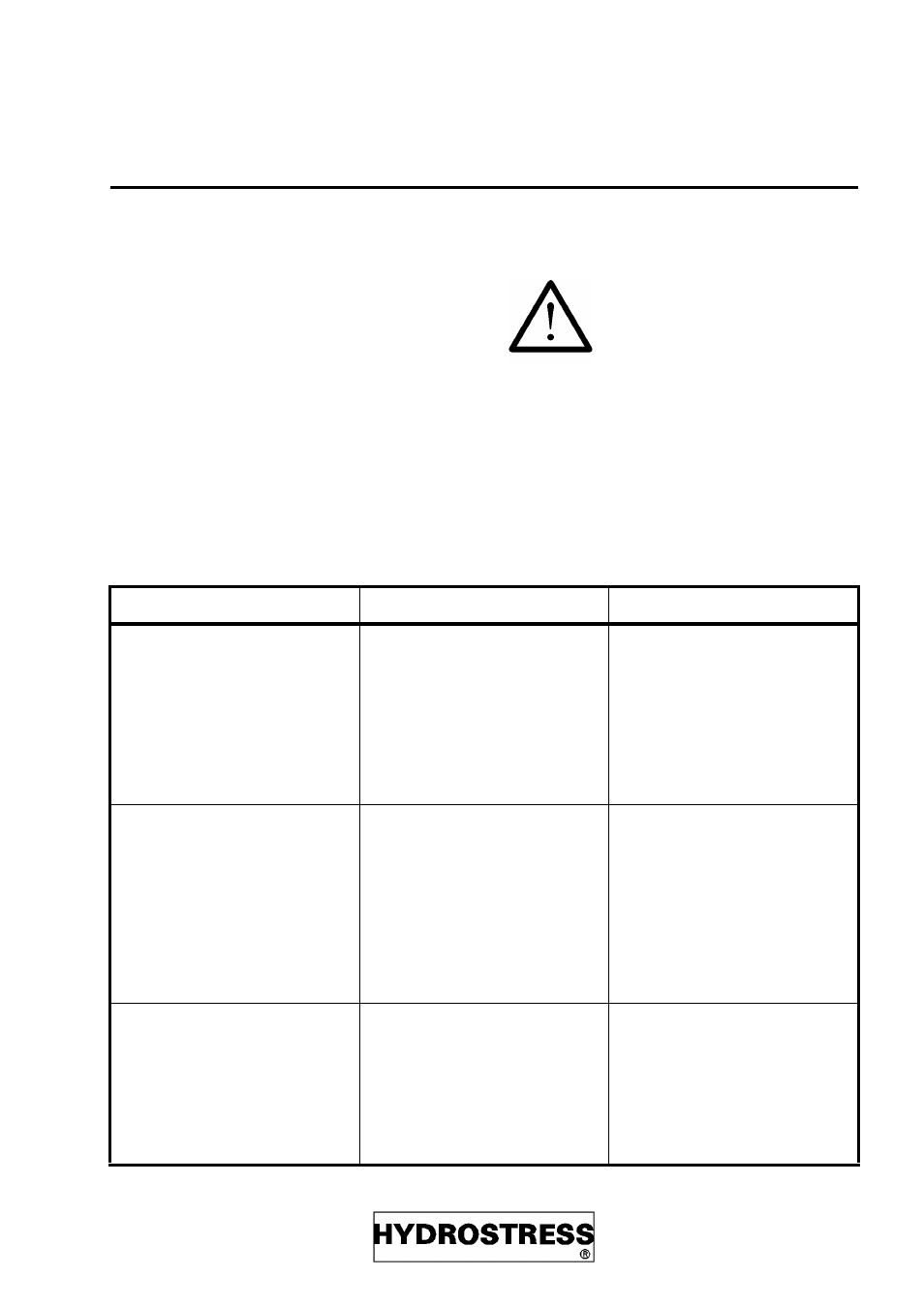

)DXOW

3RVVLEOH FDXVH

5HFWLILFDWLRQ

Wire worn flat on one side

Wire has not been twisted - or not twisted

enough

The operation was carried out on rein-

forcement steel with too much feed pres-

sure

Too small a contact surface between wire

and building object

Twist wire or increase number of twists

Work on steel with less feed pressure

Insert deflection pulley

Wire cannot be started

Wire tension too high

Wire has too many contact points with

structural object

Drive rims worn

Corners of building object are too sharp

edged

Correctly tension wire and/or slightly

reduce tension during starting

Mount deflection pulley

Replace drive rims

Round-off corners

Wire cracked

Wire pressing (connecting) incorrectly

carried out

False wire connector (screwed connec-

tor)

Loose steel or stones in building object

Improve wire pressing system

Only use knuckle connector or repair

sleeves

Cut must be relocated / insert deflection

pulley