Multichannel Systems Roboocyte2 Scripting Manual User Manual

Page 23

Appendix

23

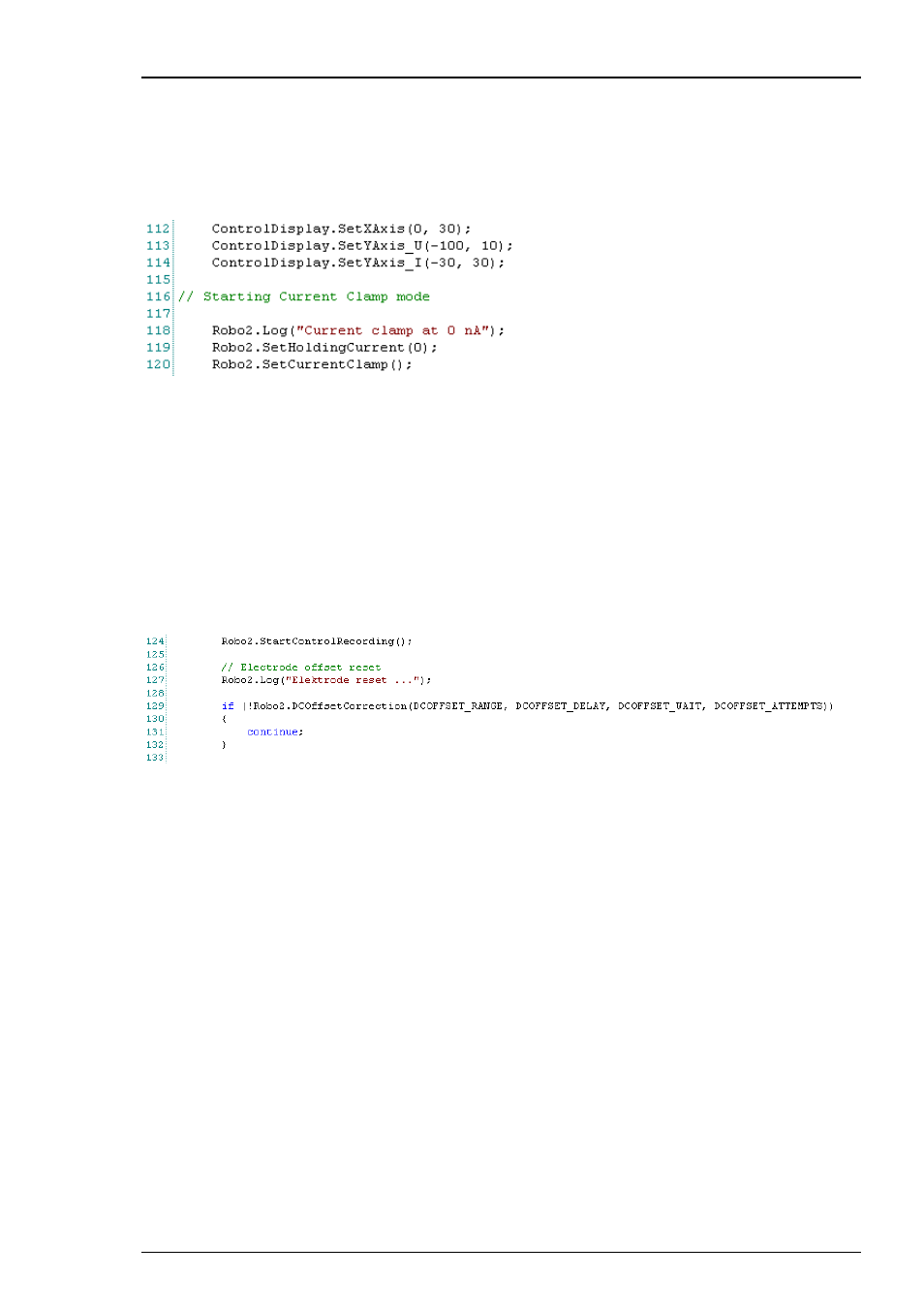

2.3.2 Switching to Current Clamp Mode

After moving the electrodes into liquid, the amplifier is set to Current Clamp Mode.

Robo2.SetHoldingCurrent(0); sets holding current to 0 nA

Robo2.SetCurrentClamp(); sets the amplifier to current clamp mode

Before starting control recording, scaling of the Control Display axes is performed. Units are

seconds, mV and nA, respectively.

2.3.3 Electrode Offset Compensation

After starting current clamp, control recording is started in order to perform electrode offset

compensation, to determine electrode resistances, and to perform the impalement of the oocyte.

Control recording means that data are displayed in the Control Display, but not saved to disk.

Robo2.StartControlRecording() starts the control recording followed by the electrode offset

compensation.

The offset compensation for both electrodes is performed by executing the command

Robo2.DCOffsetCorrection(DCOFFSET_RANGE, DCOFFSET_DELAY, DCOFFSET_WAIT,

DCOFFSET_ATTEMPTS)

Variables for the offset compensation are by default the designated predefined variables, but you

can also use numbers, such as Robo2.DCOffsetCorrection(3, 10, 5, 3) (see table in chapter 1.2.3)

The command is embedded in an if-loop, controlling what happens after the compensation: If the

electrode offset compensation was successful the script proceeds, if not, the measuring head

moves to the next oocyte.

The if loop is terminated by "continue" if the electrode offset compensation fails. "Continue"

means that the script jumps back to the start of the respective loop (oocyte loop in this case).

2.3.4 Electrode Resistance Test

After compensating the electrode offsets, the resistance of both electrodes should be tested with

the command

Robo2.ResistanceCheck_I(MIN_RESISTANCE_I, MAX_RESISTANCE_I),

where MIN_RESISTANCE and MAX_RESISTANCE are predefined variables (see table in chapter

1.2.3).