Piping/mounting, Electrical, Disassembly – MP Pumps FRX-125 INSTALL User Manual

Page 2: Inspect pump parts, Reassembly

PIPING/MOUNTING:

The pump has 1 1/4” N.P.T. inlet and 1” N.P.T. outlet pipe

connections. Use pipe sealant on the threads and other

connections. The base does not require direct mounting if

one of the pipe flanges is rigid mounted. Do not rigid mount

both the flanges and the base to avoid mounting toler-

ances that may distort the motor base. Install the pump

with the shaft in a horizontal direction. Never install the

pump vertical with the motor below the pump.

ELECTRICAL:

The motor must be protected from over current by using a

fuse or circuit breaker (see chart below for correct protec-

tion). The proper minimum wire size is stated for each

voltage application. Make sure that the pump has the

proper voltage rating to match the installation power. Do not

use or install if the voltage on the label is different than the

installation. All wire connections must be secure and sealed

to protect against arcing.

Follow all local installation codes.

MOTOR VOLTAGE FUSE/CB WIRE SIZE

ON NAME PLATE AMPS AWG

12VDC 15 14

24VDC 10 16

32VDC 6 18

110VAC 2 18

OPERATION:

The pump should be operated with liquid in the pump,

otherwise seal damage may occur. If an inlet valve is

present, the valve should always be completely open

during operation to avoid cavitation. An oulet valve may

be used to throttle the flow rate. Avoid repeated starts

and stops; the pump can operate for a long period of

time without any flow.

REPAIR AND MAINTENANCE:

The pump has a carbon/ceramic seal that may last several

thousand hours based upon the application. If the motor is

replaced, the mechanical shaft seal should also be replaced.

A seal that leaks will show leakage through the slot be-

tween the pump housing and the motor. Extreme leakage

may damage the motor bearings and contaminate the in-

side of the motor.

DISASSEMBLY:

1. Remove the four cover screws and remove the

cover discarding the o-ring.

2. Secure the motor shaft at the back of the motor and

remove the impeller by rotating it counter clockwise.

3. Remove the spring keeper, spring and rotating portion

of the seal by pulling them off by hand.

A screwdriver may be used to pry the seal up if it is sticking.

4. Remove the four capscrews that hold the

housing / adaptor assembly onto the motor. Remove

the housing / adaptor assembly and push the seal

seat out from the back side using a screwdriver.

INSPECT PUMP PARTS:

Always replace the mechanical seal. Check the seal for dry run

wear or damage. Check the motor shaft for wear at the secondary

sealing surface from the mechanical seal. If worn, replace the

motor. Check the motor bearings by rotating the motor by hand. If

the shaft rotation is not smooth or has radial/axial endplay,

replace the motor. Check the impeller running surface between

the impeller and cover. If the surfaces are worn or irregular, replace

each item.

Clean the parts that are to be reused using a solvent or mild

cleaner. Remove abrasive material.

REASSEMBLY:

1. Press the new seal seat into the pump housing.

A light lubricant may be used to aid the assembly.

Install the pump housing / adaptor assembly onto the

motor and fasten with the four capscrews.

2. Install the rotating portion of the mechanical seal

by sliding the seal (carbon side down) over the motor shaft.

Place the spring and spring keeper over the back of the

rotating portion of the seal.

3. Place the impeller onto the shaft, taking care to

pilot the spring keeper onto the shoulder at the back

of the impeller. Thread the impeller onto the motor

shaft until it bottoms out on the shaft. Thread locking

grade Loctite should be used to secure the nut.

4. Stretch the o-ring over the cover pilot. Install the cover

onto the housing and fasten the capscrews and

lockwashers.

FORM 3809A (05-07)

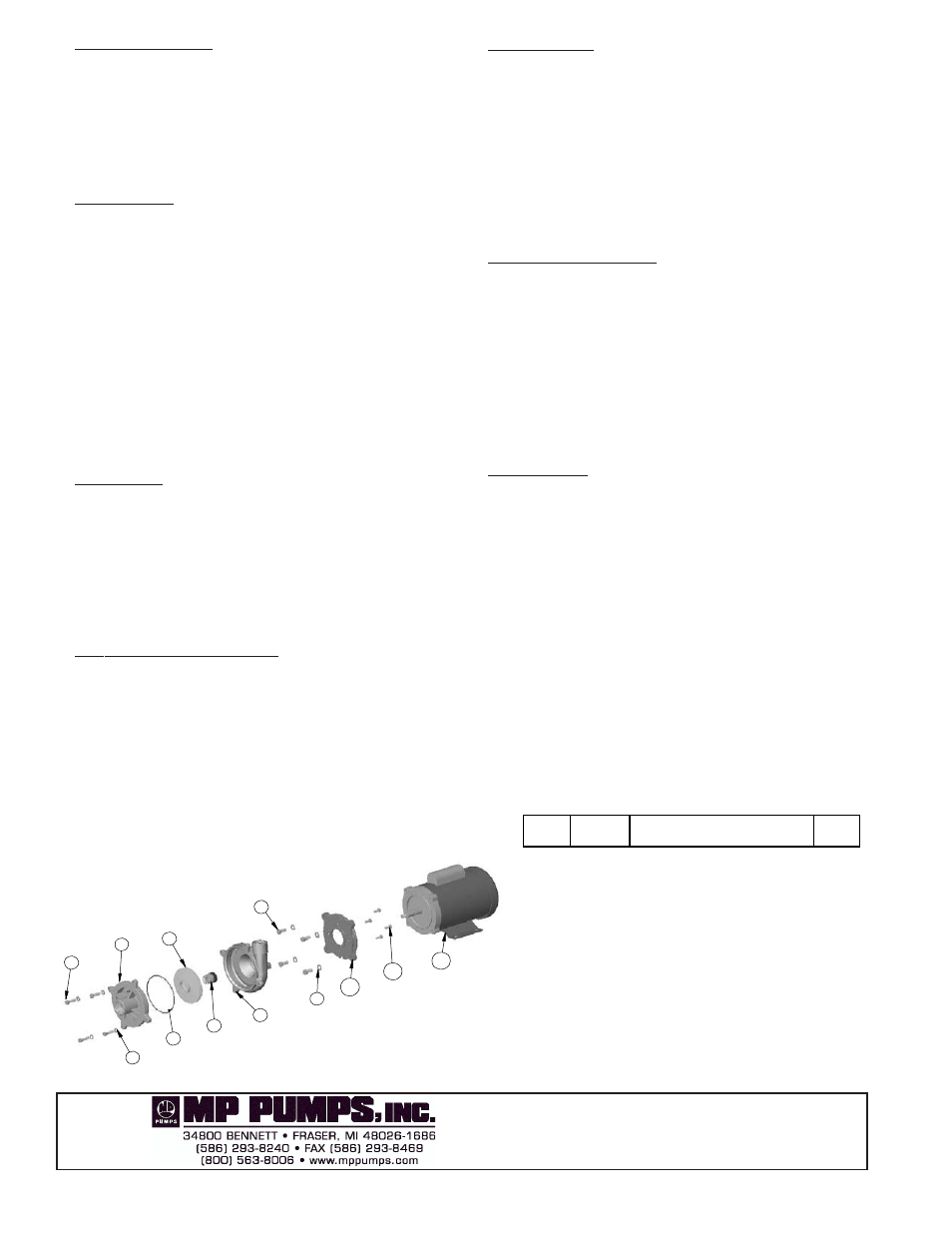

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

1

21250

CAPSCREW - S.S. - 5/16-18 X 1.13

4

2

21238

LOCKWASHER - S.S. - 5/16

4

3

35141

COVER - S.S.

1

*

4

34555

O-RING - VITON

1

5

35343

IMPELLER - S.S. - 4.45 DIA.

1

*

6

35052

SEAL - 5/8 T-21

1

7

35139

HOUSING - S.S.

1

8

21251

CAPSCREW - S.S. - 3/8-16 X 7/8

4

9

21266

LOCKWASHER - S.S. - 3/8

4

10

34928

ADAPTOR PLATE -C

1

11

21504

CAPSCREW - Z.P.S. - 1/4-20 X 5/8

4

12

35159

ELEC. MTR. - 3/4 H.P. 1 PH. 56J TEFC

1

1

2

3

4

5

6

7

8

9

10

11

12