Troubleshooting – Max Machinery 243 Helical Flow Meter User Manual

Page 16

Max Machinery, Inc.

© Copyright 2013

Rev. 002Q4

16

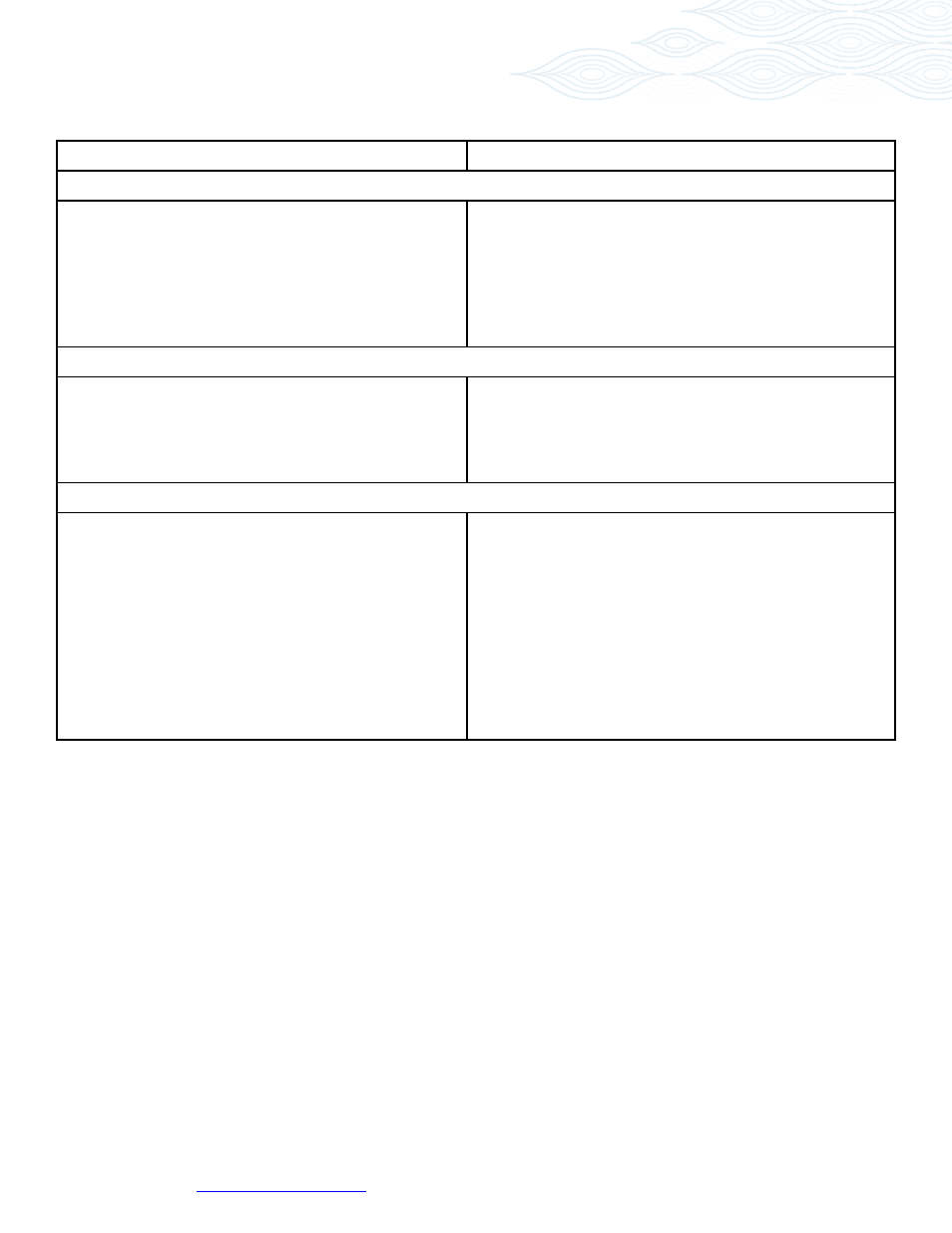

Troubleshooting

Trouble

Corrective Action

No Flow through meter or high pressure drop across meter

Solidified material blocking rotation

Debris blocking rotation

Meter broken

Heat meter to melt material.

Remove meter from line. Flush with an organic solvent or

petrochemical. Try to work debris out of the meter.

If you find damaged parts in the meter, return the

meter to the factory for repair.

Fluid is passing through the meter, but there is no indication of flow

Improper hook-up of transmitter

Verify that DC power is present at the PCA. Use a

multi-meter to measure the transmitter output

independent

of the display or PLC.

Inspect cabling.

Indicated flow does not agree with expected readings

Air in the line

Indicator not calibrated properly

Excessive reverse flow in system

Air bubbles displace the meter just as a liquid would.

If you are over-reporting, verify that there is no air in

the lines.

Verify the K-Factor for the meter in use and compare

this value to the setting used in the display.

Max transmitters have anti-dither functions which can

buffer up to 1 revolution of reverse flow. An incorrect

flow total can be reported if the pumping causes a

flow and ebb of greater than 1 meter revolution.