Ansi flangeansi flange stud torque, Ansi flange stud torque – Max Machinery 243 Helical Flow Meter User Manual

Page 12

Max Machinery, Inc.

© Copyright 2013

Rev. 002Q4

12

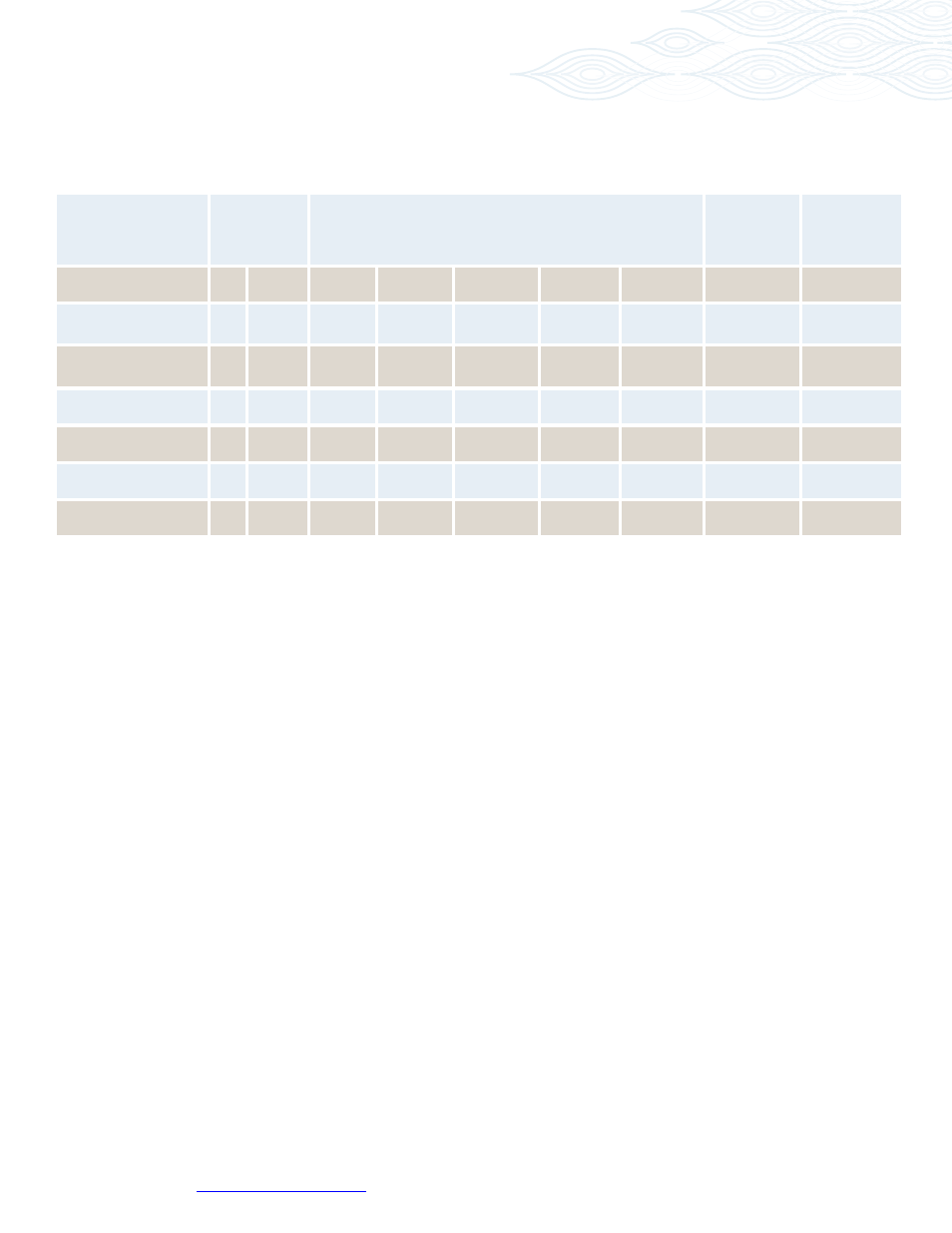

Meter

(Flange)

Studs

Torque For Line Pressure ft-lb

(N-m)

See notes below

Absolute

Max Torque

ft-lb (N-m)

Stress at

Max Torque

(psi)*

Qty Size

500

1000

1500

2500

3500

241 (600# Flange)

4

3/4-10

24 (33)

49 (67)

73 (99)

200 (271)

47,904

241 (2500# Flange) 4

1-1/8-7

37 (50)

73 (99)

110 (149)

183 (248) 256 (247) 681 (924)

47,789

242 (600# Flange)

8

3/4-10

24 (33)

47 (64)

71 (96)

200 (271)

47,904

242 (1500# Flange)

8

1-8

31 (42)

63 (86)

94 (128)

157 (213)

219 (297)

483 (656)

47,822

243 (600# Flange)

8

7/8-9

53 (72)

106 (144) 159 (216)

322 (437)

47,972

243 (1500# Flange)

8

1-1/4-7

76 (103) 151 (205) 227 (308) 378 (513)

529 (718)

965 (1310)

47,802

240 Series ANSI Flange Stud Torque Requirements. This table shows the minimum torque required for a 2:1 tightening

factor at the indicated pressures using zinc plated studs and nuts. These values were calculated using studs with a yield

strength of Sy = 75,000 psi.

ANSI Flange Stud Torque

Notes:

Using the 241, 242 or 243 meters at pressures greater than 500 psi

will require flanges. Max has bolt kits available for

flange installations.

For unplated non-lubricated nuts and studs, multiply the above torque by 1.5.

For lubricated nuts and studs, multiply the above torque by 0.9.

For cadmium plated nuts and studs, multiply the above torque by 0.8.

*Stress in bolt calculated for thread root diameter.