Mr. Gasket 6160G Fuel Filter: Billet User Manual

Billet fuel filter, Installation instructions

Mr. Gasket is a trademark of Prestolite Performance

10601 Memphis Ave. #12, cleveland, OH 44144

216.688.8300 FAX 216.688.8306

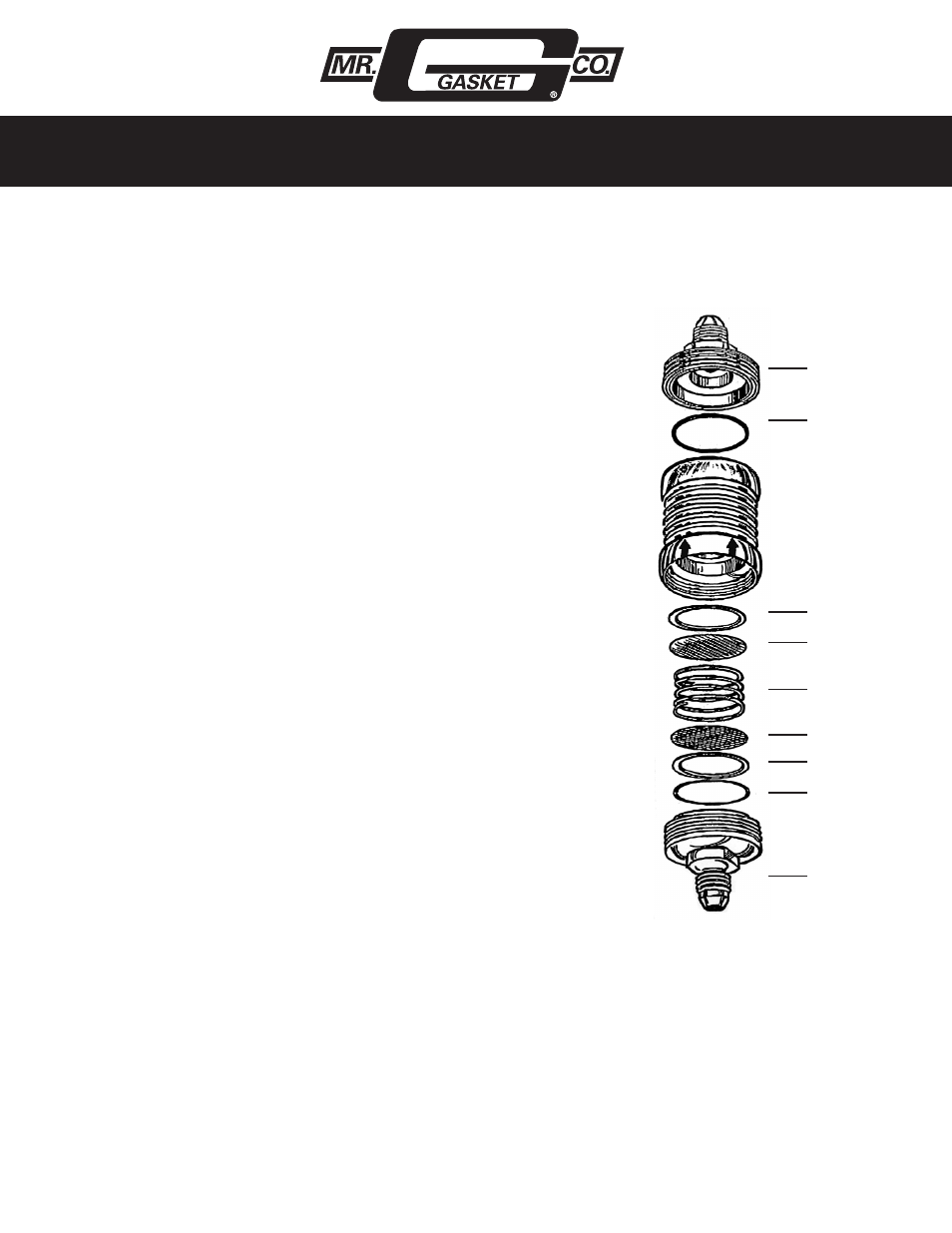

Outlet

End fitting

(may vary from

illustration)

O-ring

White non-stick

washer

Filter disc

Spring

Screen

White non-stick

washer

O-ring

Inlet

End fitting

(may vary from

illustration)

Mr. Gasket billet aluminum fuel filters can be use on low pressure carburetor or

high pressure fuel injection applications. These fuel filters are available in barbed

or AN fitting ends. Fuel flow is 15 gpm or 800 gph. This instruction sheet is for fuel

filters with barbed and AN fitting ends.

WARNING!

Allow engine to cool down (cool to the touch), this will reduce danger of flash fire if

leakage or spillage of fuel should occur. Install fuel filter inline between fuel tank and

engine fuel intake system. Select the most accessible location for ease of installation

and servicing. Filter does not need to be close to the fuel intake system

Do not install fuel filter within 3” of an exhaust component, where extreme heat can

ignite fuel. When installing or cleaning fuel filter, be sure there is no sparks or open

flames in the area. Do not over-tighten barbed hose ends or swivel coupler nuts.

Over-tightening filter ends may cause fuel leak and fire. Failure to adhere to this

WARNING could result in a fire causing serious property damage, severe bodily

injury or death.

FLEXIBLE FUEL LINES:

1) Mark a 3” section of fuel line to be removed.

2) Cut out and remove section of fuel line.

3) Thread (AN end) or insert (barbed end) fitting onto fuel line (be sure fuel flow

direction arrows are installed in the correct Inlet/Outlet position). Barbed End

Fuel Filters-Install hose clamps (correct size) and tighten to 9 in-lbs.

AN Fitting Fuel Filters-Tighten swivel coupler nut securely. Do not over-tighten!

Over-tightening hose ends may cause fuel leak and fire.

4) Check AN nuts and hose clamps to be they are secured.

5) Start engine and check for leaks.

RIGID METAL FUEL LINES:

1) Mark a 4-1/2” section of the fuel line to be removed.

2) Cut out and remove section of fuel line marked using tubing cutter.

(For best results, remove complete line.)

3) Remove burrs from tubing and clean metal particles from line.

4) Install tube sleeve and tube nut, or rubber hose (not provided), and flare ends metal line.

5) Replace fuel line, (if removed in Step 2).

6) Thread (AN end) or insert (barbed end) fitting onto fuel line (be sure fuel flow direction

arrows are installed in the correct Inlet/Outlet position). Barbed End Fuel Filters-Install

hose clamps (correct size) and tighten to 9 in-lbs. AN Fitting Fuel Filters-Tighten swivel

coupler nut securely. Do not over-tighten! Over-tightening hose ends may cause fuel

leak and fire.

7) Check AN nuts and hose clamps to be they are secured.

8) Start engine and check for leaks.

SERVICING FUEL FILTER:

1) Remove filter from fuel line. (Refer To WARNING!)

2) Unscrew end fittings from fuel filter.

3) Remove pleated filter disc and back flush to remove debris.

NOTE: For better results, use air gun.

4) Replace pleated filter disc and re-assemble fuel filter. Tighten end fittings to 9 in-lbs.

DO NOT OVER-TIGHTEN!

5) Re-install filter in fuel line, refer to previous installation steps that pertain to your installation.

6) Start engine and check for leaks.

7) Replace fuel filter element every 5,000 miles.

BILLET FUEL FILTER

INSTALLATION INSTRUCTIONS

Form 97146160 (Rev B) 01/12

www.mr-gasket.com