Magnum Venus Plastech HIS Troubleshooting Manual User Manual

Page 25

Page 23

H.I.S. Troubleshooting Manual

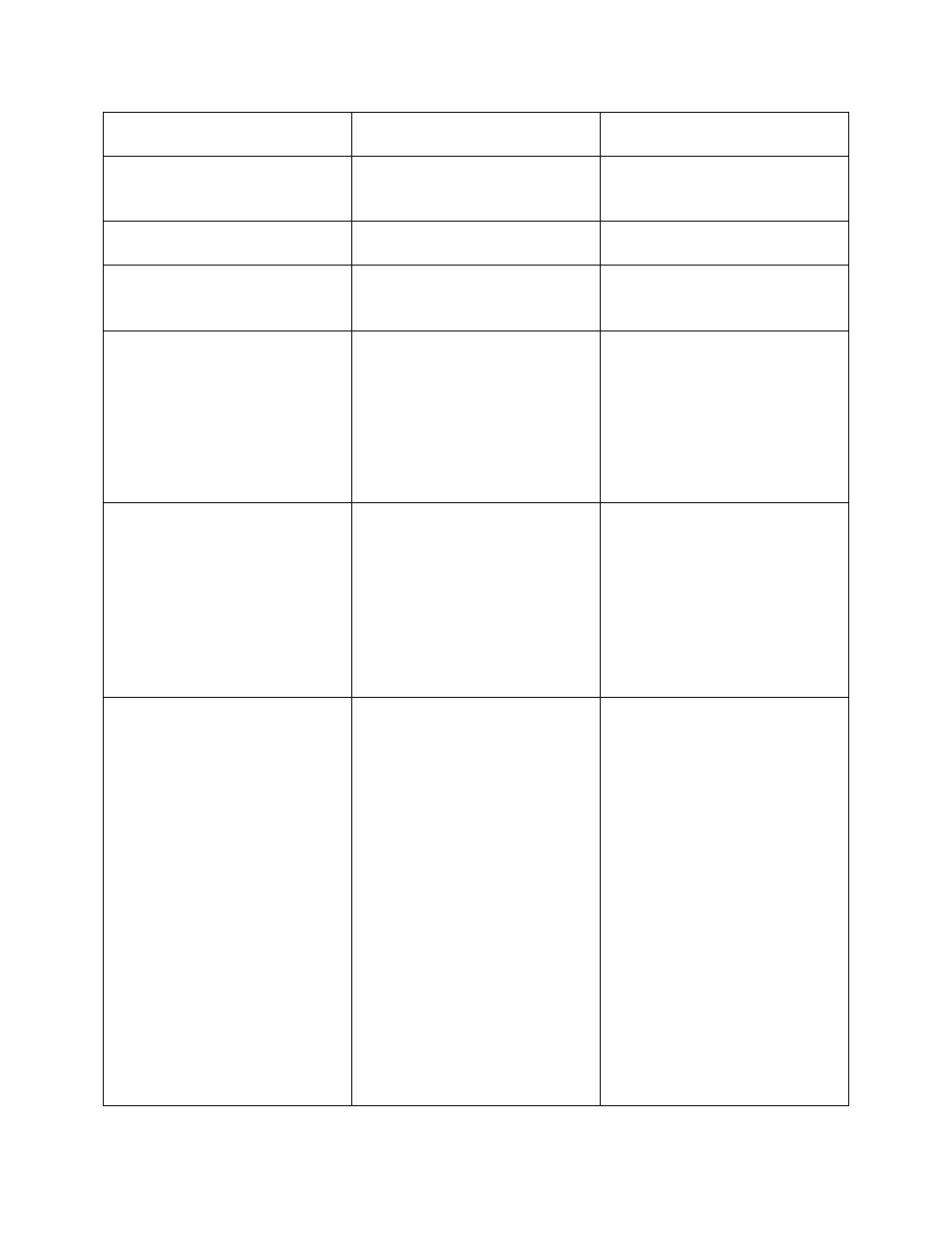

this stage are not effective.

No resin delivery on down

stroke

Foot valve, spring, spring

retainer, or foot valve ball

worn or dirty

Remove, clean/replace

parts as necessary.

No resin delivery on up

stoke

Piston cups, piston ball or

pump cylinder worn.

Remove, clean/replace

parts as necessary.

Air entering pump during

running.

Fittings on wand assembly

not tight.

Check all fittings from filter

on bottom of wand to union

on pump and retighten.

No flush solvent at gun.

No air

Set regulator air on

manifold to flush solvent

tank to 30 psi for resin and

for gel coat spraying. Set

regulator at 40 psi for

casting and hydrajecting

operations. Be sure valve

cock is on ¼ turn.

No solvent in tank.

Turn regulator to flush tank

“off”. Release air form tank

by pulling up on ring on

relief valve on lid of flush

tank. Release and remove

lid. Fill tank with solvent.

Take care to position O-ring

on cover before sealing

tank.

Blockage in flush hose or

gun.

Turn regulator to flush tank

to “off”. Release pressure

from tank. Disconnect hose

from tank and gun and blow

through with air. IF hose

does not readily pass air, it

should be replaced. Check

nipple to hose connection

on gun. Remove elbow

and nipple from gun and

check their cleanliness.

Visually examine cavity in

gun head for obstructions.

All ports and openings in

needle area of flush system

must be clean of foreign

matter. Clean all areas and

replace any and all worn or

damaged parts.