Chopper trouble shooting – Magnum Venus Plastech HIS Troubleshooting Manual User Manual

Page 19

Page 17

H.I.S. Troubleshooting Manual

Be assured, before making adjustments, that there is no glass build up between the

robber roll mandrel, idler bearing and rotor and the chopper base plate. Check to

see that all rotating parts are free running.

Note: New blades should be dulled by whetting on a piece of cardboard to

remove sharp edges.

Holding the eccentric nut for the idler bearing at the chopper base plate, with a

suitable socket wrench loosen the cap screw and rotate the bearing away from the

rubber roll. Follow the same procedure to loosen the rubber roll and rotate it away

from the blade rotor. Turning the eccentric nut in the direction that will position the

off-center hole toward the gun handle mounting hole on the chopper base plate,

position the rubber roll against the blade rotor so it touches the rotor area between

two blades. Tighten the cap screw while holding the eccentric nut. Physically check

the adjustment by holding the blade rotor and rotating the rubber roll. The tension

should be adjusted so the rubber roll will skid with a little drag against the rotor. The

idler bearing can now be properly positioned in relation to the rubber roll. Rotate the

eccentric nut for the idler bearing so the off-center hole in the eccentric will face

toward the chopper mounting of on the gun handle and the idler bearing sleeve is

against the rubber roll. Back the idler bearing off and away from the rubber roll a

very slight amount. The idler bearing should look like it touches the rubber roll but

will not rotate when the rubber roll is turned. A final check to assure the components

are properly assembled on the base plate should be made before the cover is

secured. A washer should be between the roll mandrel and the base and between

the idler bearing and the base plate. The blade rotor should be aligned edge to

edge with the rubber roll. The blade retainer and spring should approach the rubber

roll prior to the blade. The blade should be supported against the high side of the

blade slot in the rotor (i.e. on the center line). The rotor should be secured to the air

motor shaft with the set screws turned down against the flat on the shaft. Align the

step in cover with the slot on the chopper base plate. Push the cover retainer in the

receptacle and turn ¼ of a turn to secure cover.

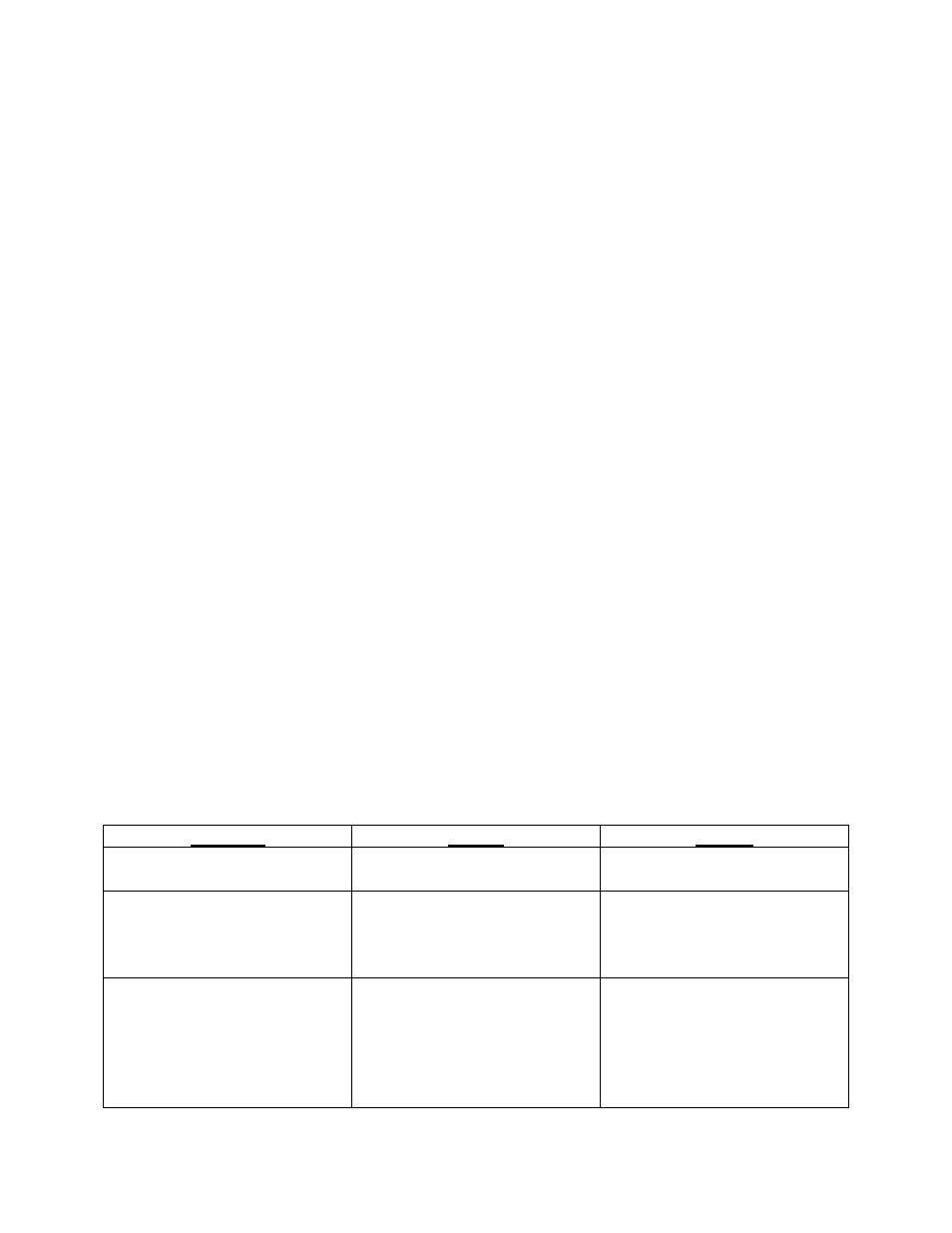

Chopper Trouble Shooting:

Problem

Cause

Action

Air motor will not run

Regulator on manifold not

on.

Set regulator so gauge

reads more than 20 psi

Manifold block

Speed control thumbscrew

on chopper manifold block

should be turned counter

clockwise until fully opened.

Air valve on gun handle not

activated by trigger bar

Squeeze trigger to full “on”

position to move poppet

stem to “on” position.

Trigger must depress

poppet stem 1/8” for full

“on” of air to Chopper.