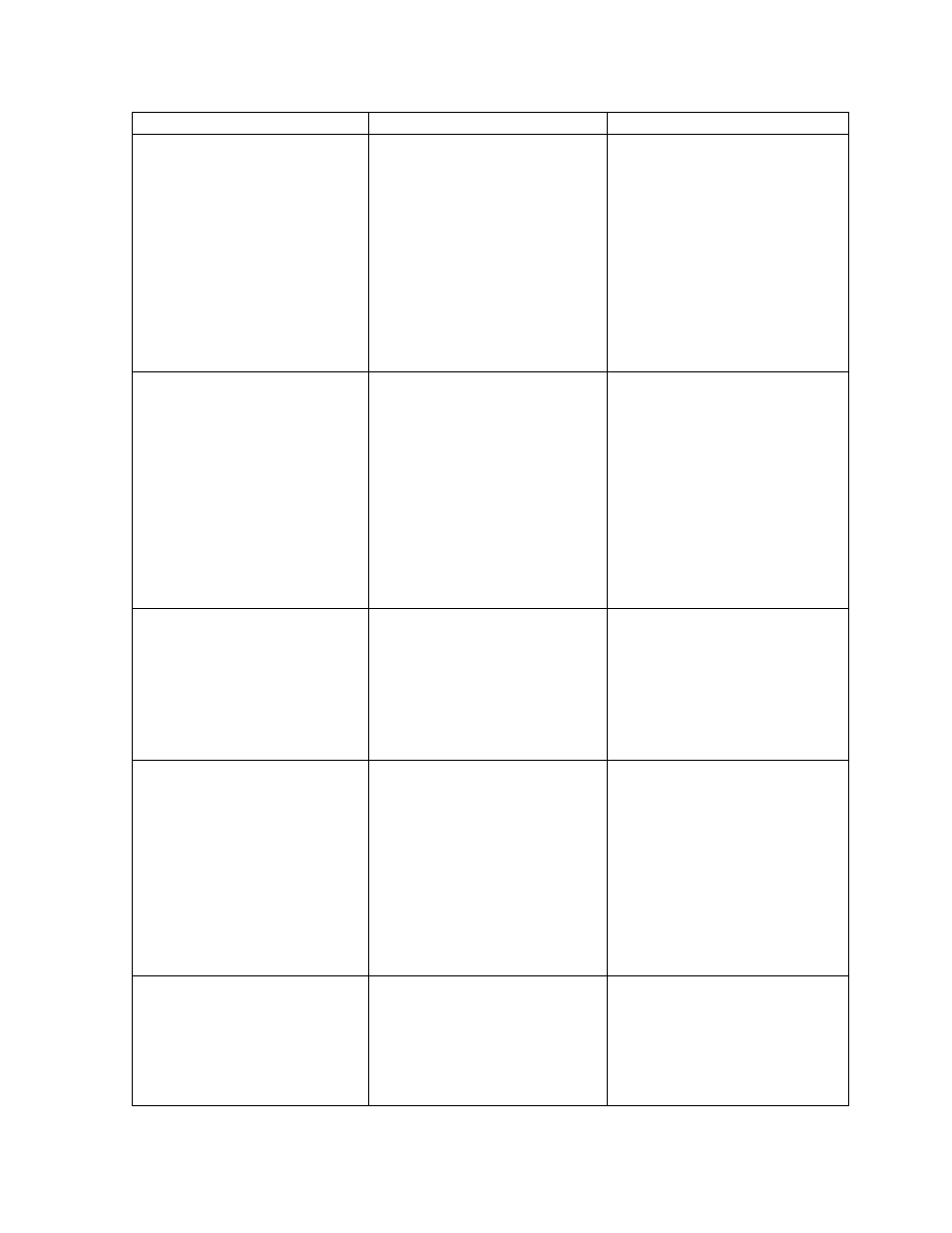

Magnum Venus Plastech HIS Troubleshooting Manual User Manual

Page 13

Page 11

H.I.S. Troubleshooting Manual

function.

Dry glass

Chopper not properly

aligned

Using swivel between gun

handle and chopper base

plate move and fix chopper

so glass is directed in the

middle of resin fan pattern.

Keep chopper down close

to gun head to allow glass

to enter resin fan between

nozzle and turbulence halo

approximately 2” from

nozzle tip.

Excessive over-shoot

Operator error

Run horizontal fan,

depositing material to

within 1” of the edge of the

mold. Run fan vertically

just within the edge of the

mold. With laminating

roller, skid material

deposited in vertical

application past the edge

of the mold for minimum

trim.

Poor saturation

Low resin volume

Increase powerhead

pressure and nozzle size

or decrease chopper

pressure. Note:

Excessive power head

pressure will create

misting and over-spray.

No pre-wet

Pre-wet mold or gel coat

mold prior to chopper or

laying mat or woven

roving. Adjust chopper for

slightly more dispensed

glass to resin ration to

compensate for pre-wet

resin applied to mold to

have corrected finished

glass to resin ratio.

Resin-rich and resin-poor

areas.

Operator error.

Check gun and chopper

for proper dispensing of

materials. Resin fan

should be wide with slight

fingers on both edges.

Glass should enter fan in