Magnum Venus Plastech HIS Troubleshooting Manual User Manual

Page 20

Page 18

H.I.S. Troubleshooting Manual

Motor frozen

Remove and repair motor.

Air motor in operating

condition should be oiled

with light-weight machine

oil, two drops every 4 hours

of operation through the

blower thumb screw (air

control valve).

Blade rotor stalls during

start and stop operation

Rubber roll too tight against

blade rotor.

Loosen cap screw on roll

mandrel and turn eccentric

nut to loosen pressure

between rubber roll and

blade rotor. Correct tension

is applied when rubber roll

can be skidded on blade

rotor when blade rotor is

held in position and roll is

turned.

Blade not fully depressed

on rotor

Push blade to bottom of

blade slot in rotor with small

block of wood.

Chopped strands not

uniform length

Worn or damaged blades or

rubber roll.

Blades must be free of

nicks and breaks. New

blades should be dulled by

whetting on cardboard to

remove keen hair edges

prior to installation.

Grooves, glass cuts in

rubber roll, or other

irregular markings on

surface caused by worn

blades requires a change in

rubber roll.

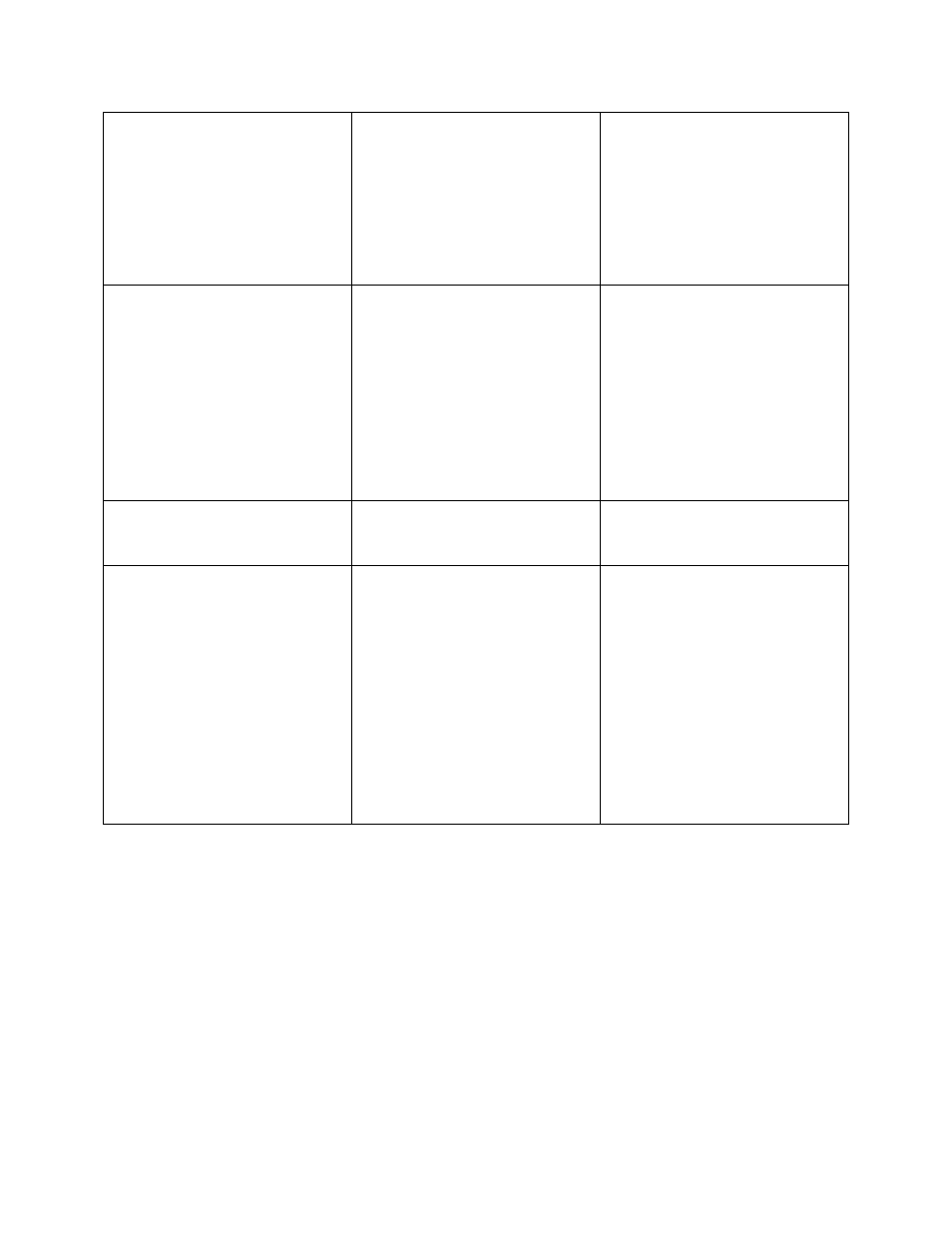

Clam Shells

Magnum Venus Pump Packing Removal Tool:

The clam shells are tools to assist the removal of the packing in the center casting of

the resin pumps. The proper tool for your pump is supplied with the pump. The

following will explain their use:

1. Remove the piston cylinder from the bottom of the pump and the spring retainer

and spring above the pump piston.

2. Slowly apply air to the pump to raise the piston to the top of the stroke.