Pg.9, Disassembly procedure reassembly procedure – Liquid Controls Precision Turbine Flowmeters User Manual

Page 11

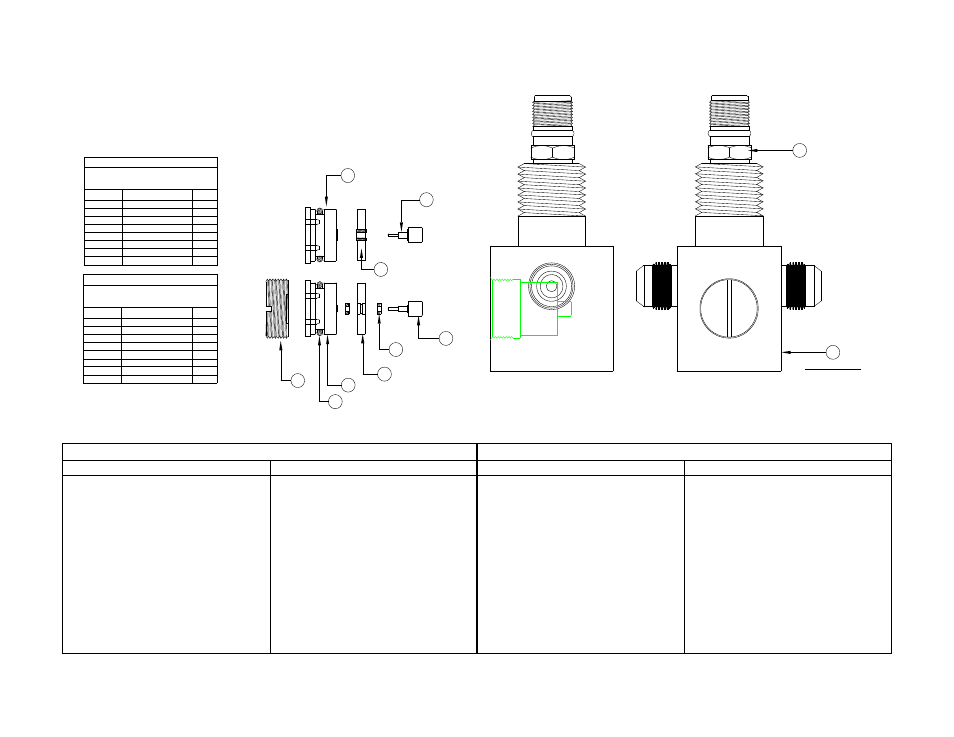

FIGURE 4: MF100-175 LO-FLO SERIES FLOWMETER

SLEEVED BEARING INTERNALS

1

1

1

1

1

1

PICKUP COIL

RETAINER

SCREW PLUG

HOUSING

H

B

A

QTY

DESCRIPTION

DESIGNATOR

ROTOR/BEARING ASSY

.

C-2

O-RING****

A

AN FLARE SHOWN

D-1

C-1

B

C-2

E

D-1

SHAFT

1

G

F-2

H

D

F-1

F-2

G

**** CONSULT FACTORY FOR O-RING MATERIALS

AND INSTALLATION.

F-1

C-1

SHAFT

E

D

O-RING****

1

1

1

2

1

1

1

1

BALL BEARING INTERNALS

PICKUP COIL

BEARING

ROTOR

RETAINER

SCREW PLUG

HOUSING

H

G

B

A

QTY

DESCRIPTION

DESIGNATOR

This assembly references all Model Numbers

This assembly reference's all Model Numbers

with Teflon Ball (TB), Metal Ball (MB) and

with Graphitar (GS), Teflon (TS), Carbide (CS)

and Fluorosint (FS) sleeved bearing designator.

Cryo Ball (CB) bearing designator.

INTERNAL ASSEMBLY IS

TYPICAL FOR NPT, TUBE FITTING,

HIGH PRESSURE, FNPT & FLANGED

STD. LO-FLO SERIES.

DISASSEMBLY PROCEDURE

REASSEMBLY PROCEDURE

FOR BALL BEARING

FOR SLEEVED BEARING

FOR BALL BEARING

FOR SLEEVED BEARING

1. With a large screw driver, remove screw

plug.

2. Insert 4-40 screw into either of the tapped

holes on the face of the retainer and

extract from housing.

3. Remove bearings and rotor. It is not

necessary to remove shaft.

4. Review all parts for damage.

A. Check bearings thoroughly.

B. Check o-ring for cracks/nicks.

Replace if evident.

1. With a large screw driver, remove screw

plug.

2. Insert 4-40 screw into either of the tapped

holes on the face of the retainer and

extract from housing.

3. Remove rotor/bearing assembly. It is not

necessary to remove shaft.

4. Review all parts for damage.

A. Check bearing faces and bore

thoroughly.

B. Check o-ring for cracks/nicks

Replace if evident

NOTE: If any part appears damaged,

DO

NOT REASSEMBLE, call factory for

instructions.

1. Insert bearings into rotor and insert in

housing on shaft.

3. Insert retainer (with o-ring) and remove

4-40 screw.

4. Screw in screw plug.

NOTE: If any part appears damaged,

DO

NOT REASSEMBLE, call factory for

instructions.

1. Place rotor/bearing assembly on shaft in

housing.

2. Insert retainer (with o-ring) and remove

4-40 screw.

3. Screw in screw plug.

For liquid applications: Internals work best

when wet.

Pg.9