Maintenance, Turbine meter disassembly, Turbine meter assembly – Liquid Controls CIM100 User Manual

Page 9

MaIntenance

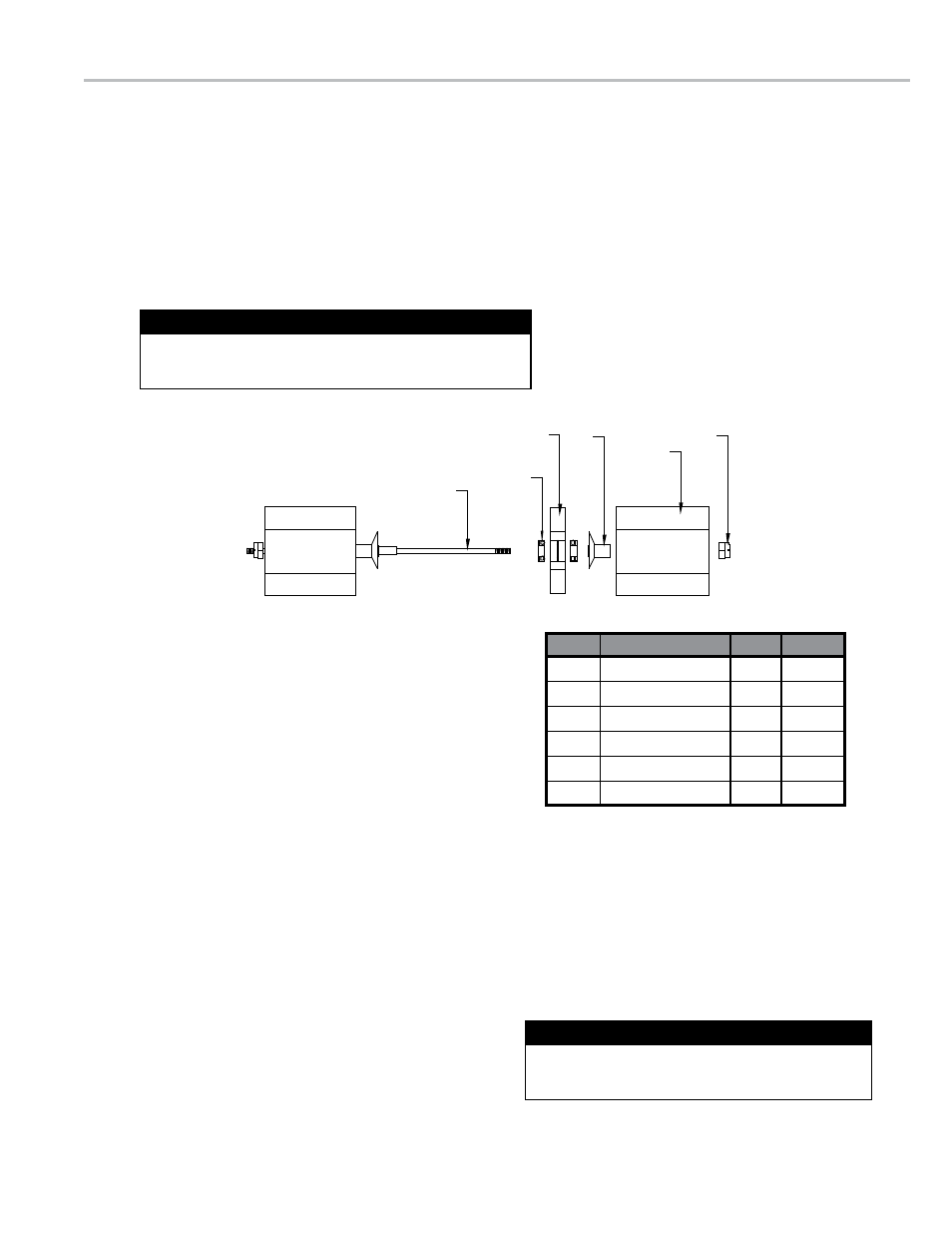

turbine Meter disassembly

1... Remove.lock.nut.from.shaft.end.on.the.inlet.side.

2... Insert.extraction.hook.into.inlet.clip.assembly.and.extract.with.a.parallel.pulling.motion.

3... Remove.cone,.bearings.and.rotor..

4.. Remove.outlet.clip.assembly.with.extraction.hook.as.directed.in.step.2..

Do not remove lock nut from outlet side clip

assembly..Leave.clip,.cone,.shaft.and.nut.assembled..(Refer.to.diagram)

1. Removal of internals should be performed in a clean area.

2. Ensure that internals are clean and dry before reassembling.

Assembly Notes

Item

DescrIptIon

Qty

part #

A

Bearing

2

PB-1

B

Rotor

1

PHL-1BB

C

Cone

2

CN1B-6

D

Clip Assy

2

CL1-6

E

Lock Nut

2

HS005

F

Shaft

1

SH1-6

turbine Meter assembly

1... Place.meter.on.table.vertically,.outlet.side.up.

2... Insert.outlet.clip/cone/shaft/nut.assembly.into.the.housing..Push.down.until.the.assembly.is.seated.against.the.step.in.the.

housing..Clip.bundle.diameter.may.need.to.be.clamped.for.easier.insertion.

3... Flip.meter.so.the.inlet.side.is.up..Insert.bearing,.rotor,.bearing,.then.cone..

4... Insert.inlet.clip.assembly.

5... Screw.on.lock.nut.snug.against.inlet.clip

If any part appears damaged “DO NOT REASSEMBLE”.

Call factory for instructions.

Damaged Parts

F

A

B

C

D

E

9