Controlled Products Systems Group 104301 User Manual

Page 8

8

FAAC Model S418 Swing Gate Operator

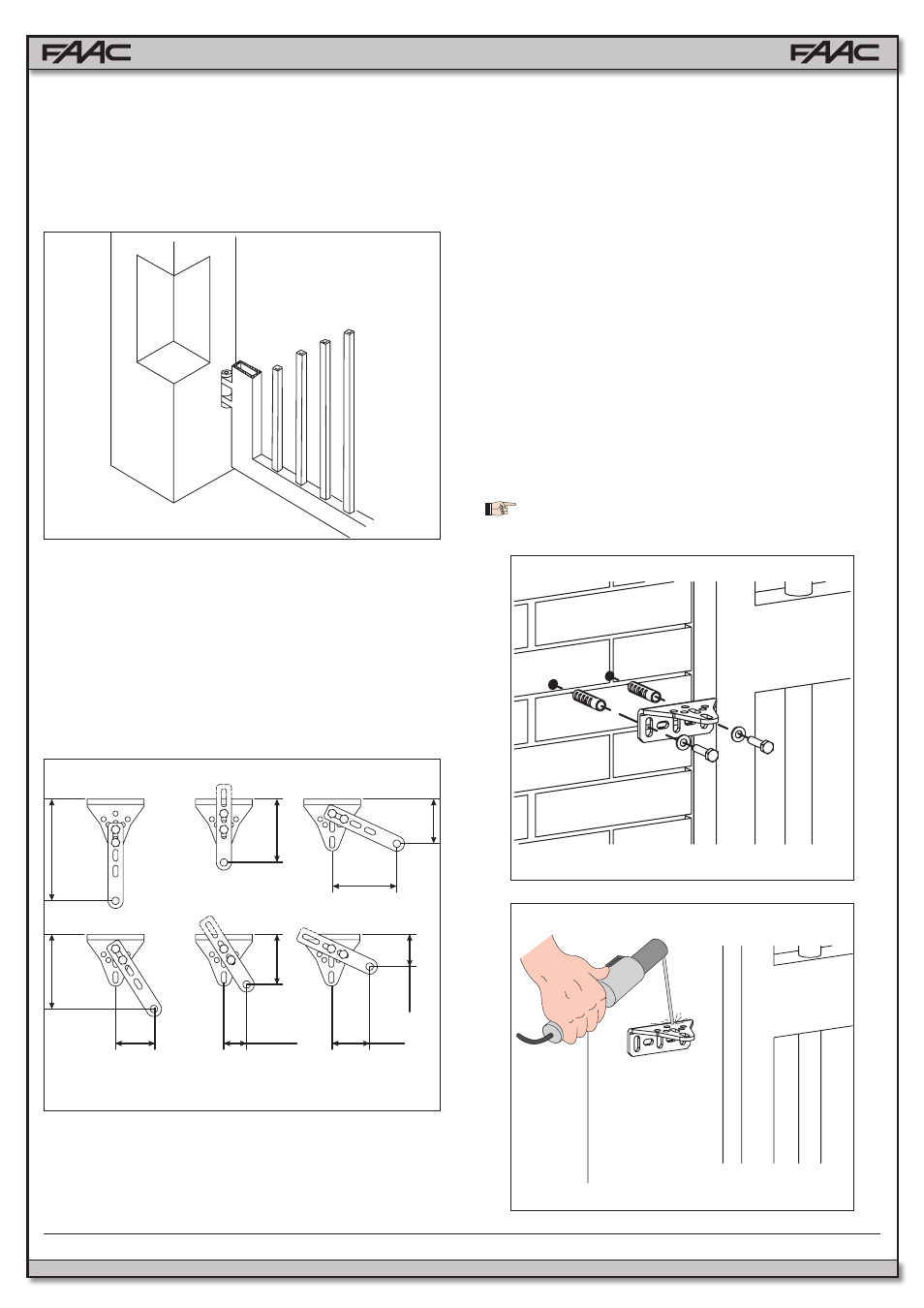

If the size of the pillar or the position of the hinge does

not permit the proper installation of the operator, a niche

will have to be made in the pillar (as indicated in Figure 6)

in order not to change value

A (Figure 4). The size of the

niche must be such as to permit an easy installation of the

operator, not limiting its rotation and allowing activation of

the manual release device.

Fig. 8

Fig. 9

Fig. 6

The rear bracket is adjustable to different positions, which

limits modifications necessary to satisfy installation values

A and B.

Figure 7 shows some of the positions that the bracket can

take; all the positions intermediate to those shown may be

obtained.

The positions chosen must permit the assembly of the

bracket using both securing screws.

3.3.1 General Rules for Determining Installation Values

• To obtain opening of the leaf to

90°: A+B=C.

• To obtain opening of the leaf more than

90°: A+B

• Lower A and B values produce higher peripheral leaf

speeds.

• Limit the difference between value A and value B to within

1

½ inches, greater differences may cause variations in

speed during opening and closing gate movements.

• Maintain a Z value that keeps the operator from striking

the pillar.

• The mechanical stops intervene during the first and final

1

½ inches of the stroke. Not utilizing the entire operator

stroke could limit the possible adjustments or reduce

them to zero.

3.4

INSTALLING THE OPERATOR

To correctly install the operator, follow the procedure below:

1. Secure the fixed part of the rear bracket in the position

determined previously, using suitable assembly systems.

In the case of iron pillars, the bracket may be welded

directly to the pilaster, see Figures 8 and 9.

During assembly procedures, check that the bracket is

perfectly horizontal using a level.

6½

4⅞

4⅛

4¼

2⅞

2

2½

3¼

1½

2½

Fig. 7

Dimensions in Inches