Controlled Products Systems Group 104301 User Manual

Page 11

11

FAAC Model S418 Swing Gate Operator

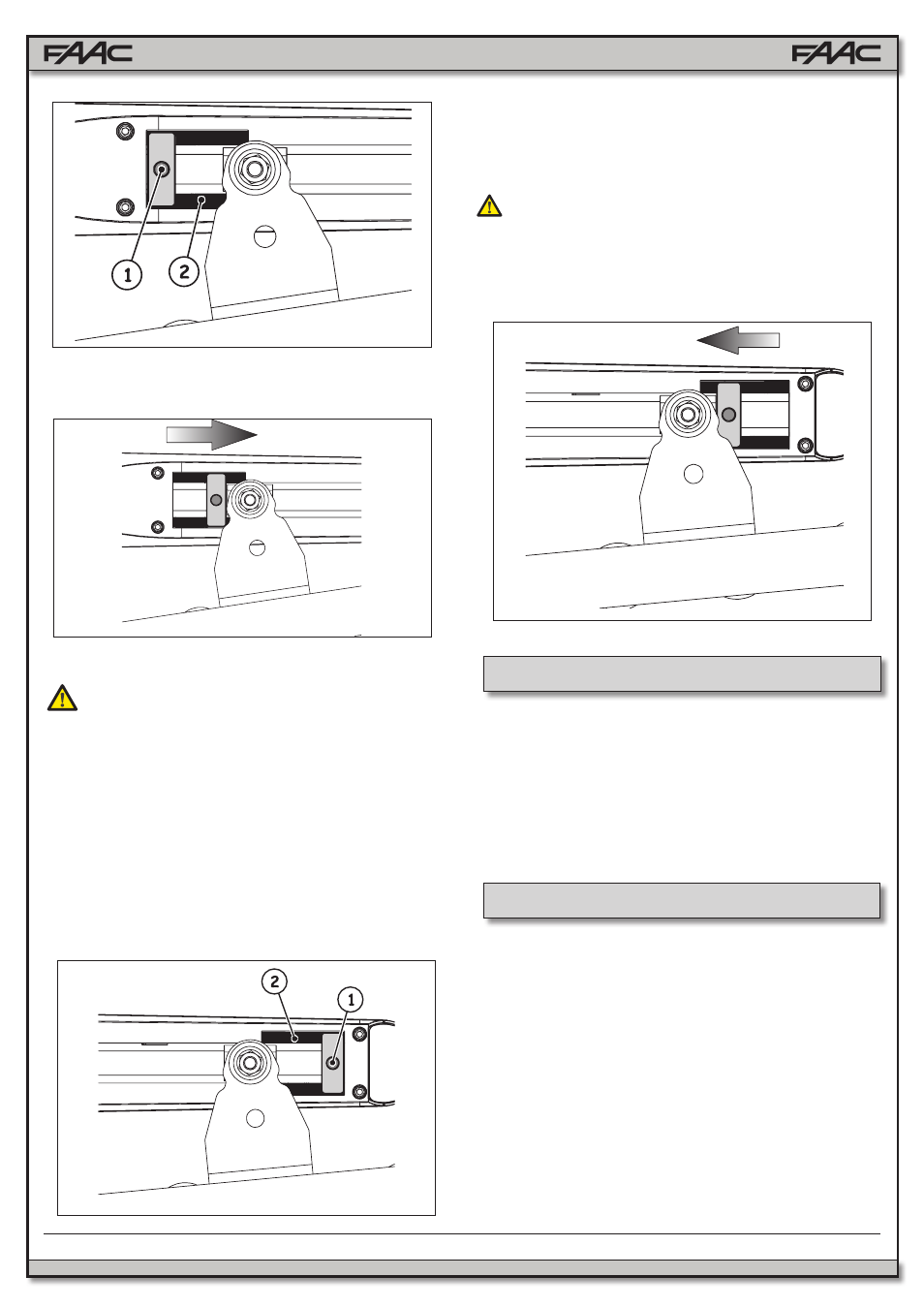

Fig. 19

Fig. 20

Fig. 21

Fig. 22

5. Tighten the securing screw once again.

The mechanical stop is coupled to a toothed

sector, Figure 19 Ref. 2.

In the case of obstructions during movement,

check that the coupling is free. DO NOT FORCE

IT.

4. Move the mechanical stop until it is close to the

front fitting, as indicated in Figure 20.

3.6.2 Mechanical Stop at Closing

1. Prepare the operator for manual operation, see

Section 5.

2. Manually move the leaf into its closing position.

3. Loosen the securing screw, Figure 21 Ref. 1. The

screw does not need to be completely removed.

4. Move the mechanical stop until it is close to the

front fitting, as indicated in Figure 22.

5. Tighten the securing screw once again.

The mechanical stop is coupled to a toothed

sector, Figure 21 Ref. 2.

In the case of obstructions during movement,

check that the coupling is free.

DO NOT FORCE IT.

• Once all necessary electrical connections have

been made, power up the system and program

the control unit based on your individual needs

(see relevant instructions).

• Perform a test of the automated system and of all

connected accessories, paying special attention

to safety devices.

4.

AUTOMATED SYSTEM TEST

If the automated system needs to be moved manually,

due to a power outage or operator malfunction, perform

the following steps to release the device:

1. Switch off the power supply to the system.

2. Slide off the protective cap, Figure 23 Ref. 1.

3. Insert the supplied release key, Figure 23 Ref. 2,

and turn it counter-clockwise until it stops, Figure

23 Ref. 3. The release position is indicated by

an open padlock.

4. Move the leaf manually.

5.

MANUAL OPERATION