Manual operation – Controlled Products Systems Group -108710 User Manual

Page 12

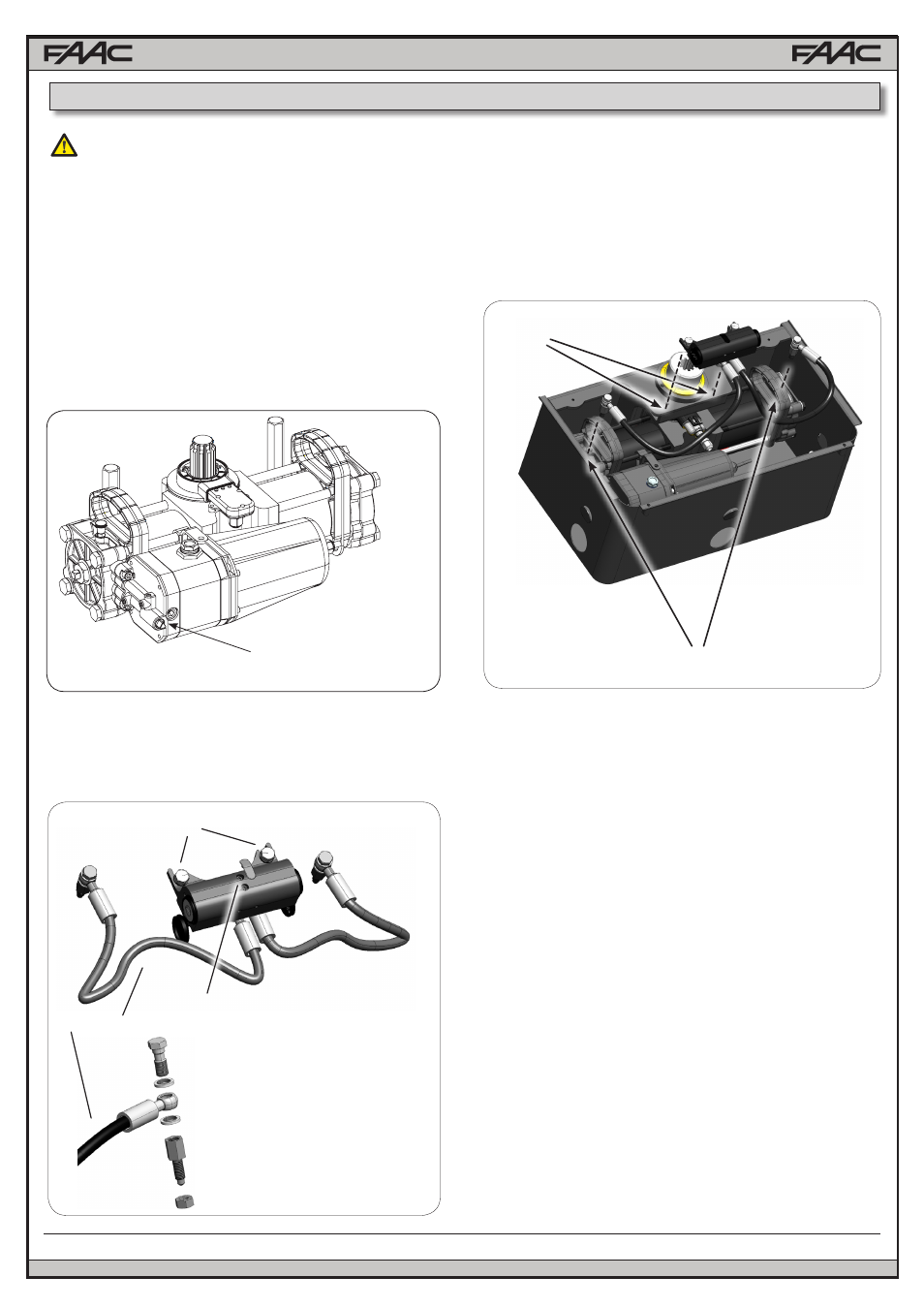

Fastening bolts for the release system

Bleed screws

Fig. 18

Banjo Bolt

Hydraulic Hose

Union bolt

1

Fig. 19

4.2.1 INSTALLATION PROCEDURE

The installation of the hydraulic release could have let air in the

circuit, causing irregular operation like an incorrect movement

of the leaf and excessive noise during operation.

To solve this problem, operate as follows:

1) Command an opening movement of the gate.

2) During the leaf movement, loosen the opening bleed screw

(Fig.20 ref.1 )

3) Let air come out from the hydraulic circuit through the bleed

screw until non-emulsified oil comes out.

4) Tighten the bleed screw before the operator ends the opening

cycle.

5) Command a closing movement of the gate.

6) During the leaf movement, loosen the closing bleed screw

(Fig.20 ref. 2)

7) Let air come out from the hydraulic circuit through the bleed

screw until non-emulsified oil comes out.

8) Tighten the bleed screw before the operator ends the closing

cycle.

9) Repeat the operations, if necessary.

10) Restore the oil level until it is just under the cap, using the

oil supplied (Fig. 21 ref.1).

2

4.2.2 BLEEDING PROCEDURE

The S800H operator kit comes with a field installable hydraulic

manual release, that can be conveniently mounted on top of

the load bearing box

1) Release the operator using the built in hydraulic release

2) Fasten the external release body to the load bearing box

system using the two supplied M8 screws (fig. 19 ref. 1)

3) Remove the bleed unions on the operator, then connect

those supplied with the release system (Fig. 19 ref. 2

3) Re-lock the built in manual release.

If the gate has to be moved manually due to a power cut or

fault of the automated system, you can use the hydraulic

release device with the release key (Fig.17):

1) Remove the cover from the bearing case.

2) Turn the release screw

- To RELEASE, turn the screw counter-clockwise by one turn.

(DO NOT COMPLETELY UNFASTEN THE SCREW TO AVOID

SPILLING THE OIL.

- To re-engage the hydraulic operation, turn the screw

clockwise up to the mechanical stop point. (DO NOT

OVERTIGHTEN)

RELEASE SCREW

Fig.17

4.1 BUILT IN HYDRAULIC RELEASE

MAKE SURE TO CUT POWER BEFORE RELEAS-

ING OR LOCKING THE OPERATOR

4. MANUAL OPERATION

4.2 EXTERNAL HYDRAULIC RELEASE

12

FAAC Model S800H Swing Gate Operator