Controlled Products Systems Group -108710 User Manual

Page 11

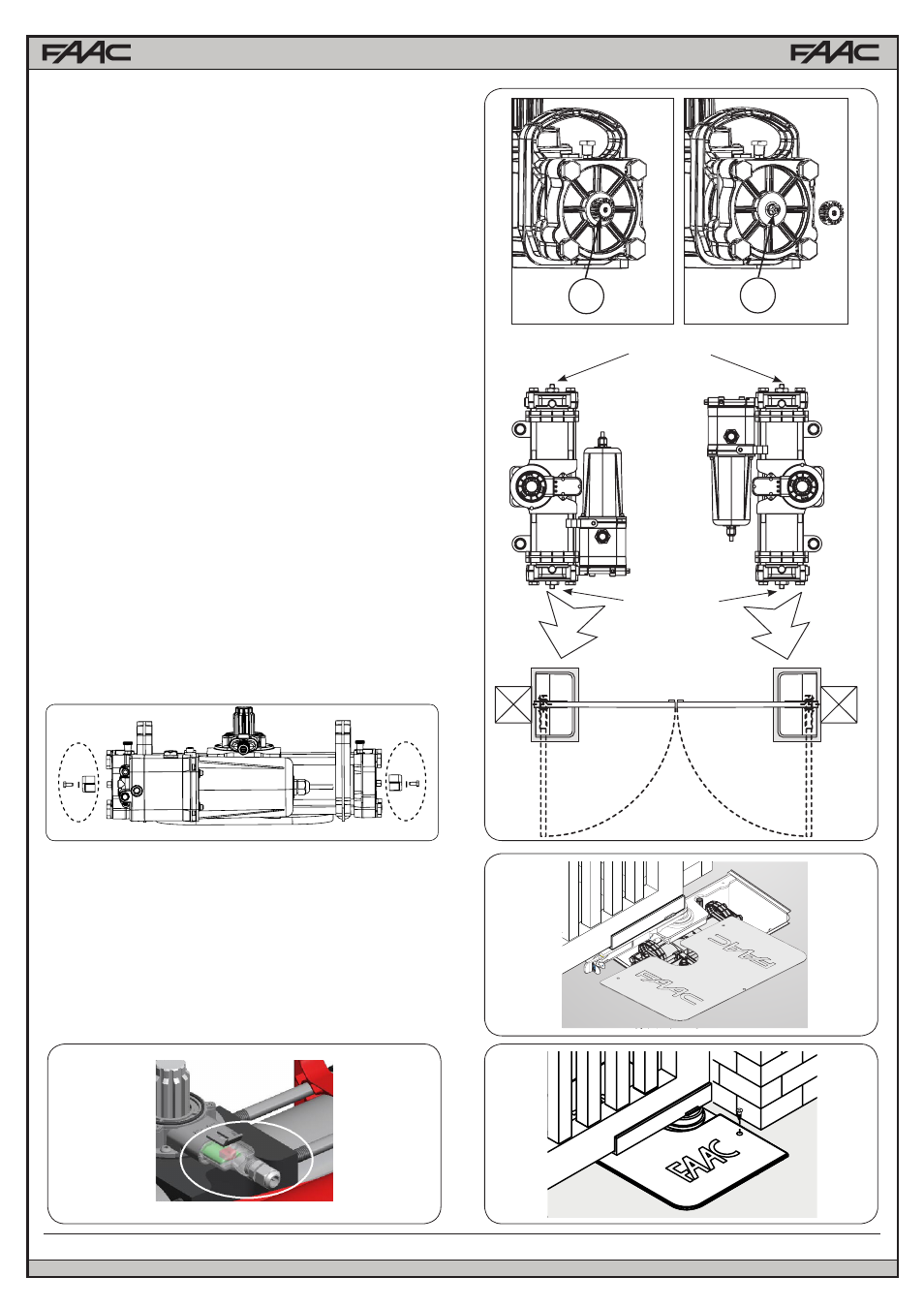

1

2

A

B

The S800H operator is supplied standard with internal opening

and closing mechanical stops. This is to facilitate the installation

operations because there is no need to build external mechanical

stops.

The mechanical travel-limit stops (POSITIVE STOPS) can be

adjusted in the last 30° of the operator’s MAXIMUM travel, at

both opening and closing.

FAAC SUPPLIES THE TRAVEL LIMIT DEVICES TOTALLY OPEN

( MAXIMUM PINION ROTATION ANGLE ).

TRAVEL-LIMIT

STOP AT OPENING

TRAVEL-LIMIT STOP AT CLOSING

1) Hydraulically release the operator. (See chapter 4.1)

2) Close the leaf, manually taking it into its closed position.

3) Unscrew the cap (Fig.12 ref.A) of the closing travel-limit screw

(Fig.12 ref.1)

4) UNSCREW the travel-limit stop screw (Fig.12 ref.B) at closing

(Fig.12 ref.1), until the leaf begins to move.

5) Fasten the supplied U-bracket (Fig.13) on the travel-limit stop

screw.

6) Open the leaf, manually taking it into its opening position.

7) Unscrew the cap of the screw (Fig.12 ref.A) of the opening

travel-limit stop (Fig.12 ref.2).

8) UNSCREW the travel-limit stop screw (Fig.12 ref. 2), until the

leaf begins to move.

9) Fasten the supplied U-bracket (Fig.13) on the travel-limit stop

screw.

10) Open and close the gate to check if the travel-limit stop is

correctly adjusted.

11) Re-lock the operator again, following the instructions in

chapter 4.1.

CLOSING POSITION

OPENING POSITION

Fig.12

Fig.15

Fig.16

1) Place the encoder in its slot on the motor (See Fig. 14).

2) Connect the motor (Fig.1 ref. 8) and the encoder (Fig.1

ref. 9) to the control unit, following the specific instructions.

3) Secure the cover of the load bearing box with the supplied

screws (Fig.15;16).

4) Place the warning sings on both sides of the gate

3.1 INTERNAL MECHANICAL POSITIVE STOPS

3.2 ADJUSTMENT OF THE TRAVEL-LIMIT STOPS

3.3 FINAL STEPS

Fig.13

Fig.14

11

FAAC Model S800H Swing Gate Operator