Controlled Products Systems Group 1042001 User Manual

Page 8

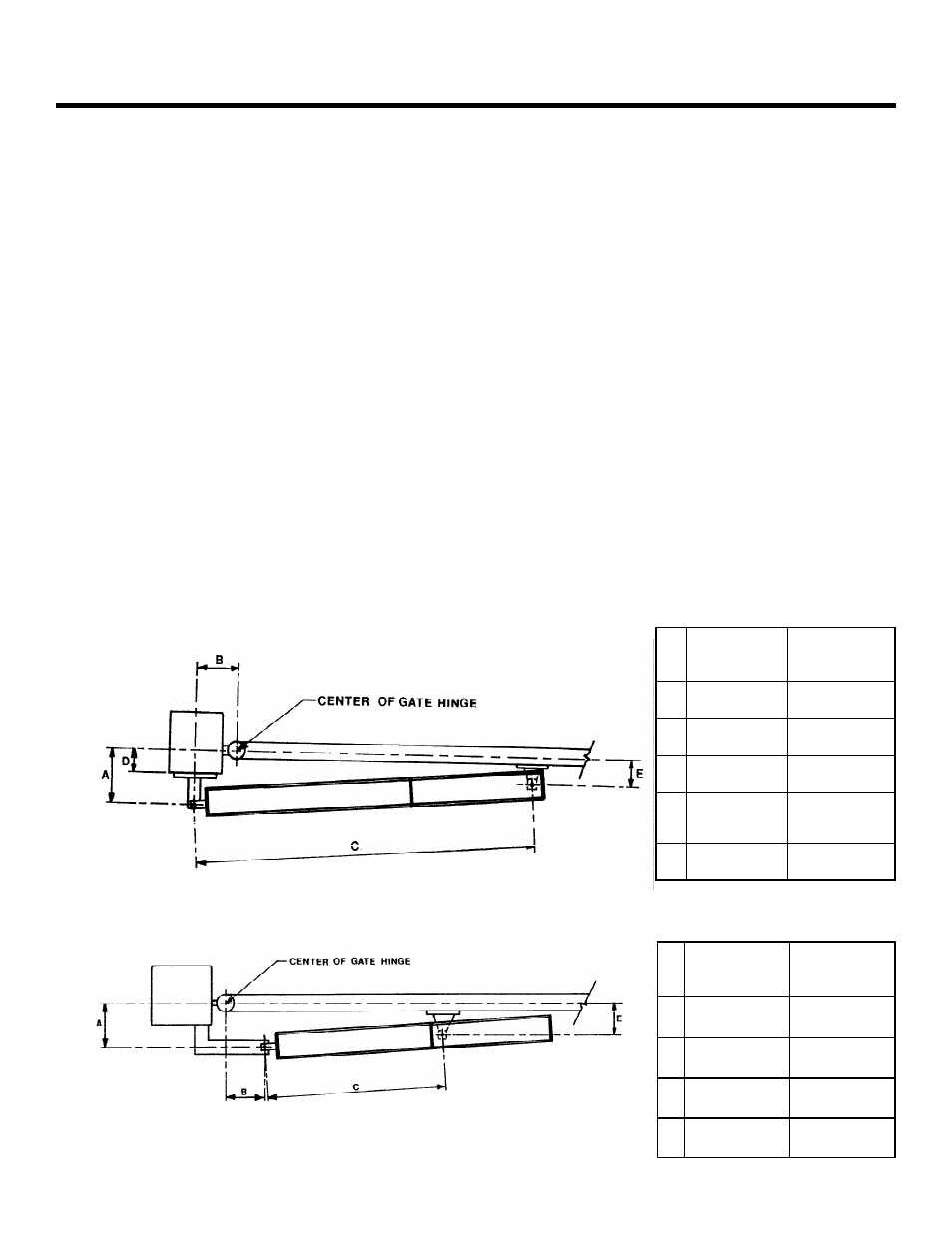

Figure 4. An inward swinging gate, top view: important mounting dimensions

Figure 5. An outward swinging gate, top view: important mounting dimensions

422

Standard

A

4-3/4 in.

( 12 cm)

B

4-3/4 in.

(12 mm)

C

27 in. (673

mm)

E

Must be

less than A

422

VHS

3-1/8 in.

(8 cm)

3-1/8 in.

(8 cm)

23-1/4 in.

(59 cm)

Must be

less than A

422

Standard

A

4-3/4 in.

(114 mm)

B

4-3/4 in.

(114 mm)

C

36-5/8 in.

(93 cm)

D

Max

2-3/4 in.

(7 cm)

E

Must be

less than A

422

VHS

3-1/8 in.

(8 cm)

3-1/8 in.

(8 cm)

29-3/4 in.

(75.5 cm)

Max

1-1/8 in.

(2.9 cm)

Must be less

than A

Page 8

December, 2003

422 Operator And

455 D Control Panel Installation Manual

Hold the front mounting bracket flush against the gate.

Mark the location of the front mounting bracket.

Remove the operator from the gate. Remove the front

mounting bracket from the swivel joint.

Note:

Clamping the front mounting bracket at the

marked location before checking the swing, as

instructed below, will ensure proper location of the

front mounting bracket.

Bolt or weld the front mounting bracket to the marked

location on the gate.

WARNING!

Do no weld the front mounting

bracket with the operator attached. Doing so will

seriously damage the operator.

A

TTACH

THE

O

PERATOR

TO

THE

G

ATE

Re-attach the operator to the mounting brackets. Once

the operator is mounted and level, remove the vent

screw from the bottom of the rear flange. (See Figure 1)

Use the 3mm hex key on the end of the screwdriver

provided.

WARNING!

Failure to remove the vent screw

may result in erratic operation of the operator or

blown

seals.

Slowly move the gate open and close.

WARNING!

The piston should not bottom out in

either direction. Doing so will seriously damage

the

operator.

Be sure that the gate reaches the positive stop before the

piston bottoms out. Adjust the swivel joint if necessary.

After checking the swing of the gate, secure all nuts and

bolts, including the jam nut on the swivel joint.

Once the operator is secure, install the protective cover

over the piston of the operator, first insert the two spacers

(items labeled 2 in Figure 6) in the front flange of the

operator as shown. The spacers dampen any vibrations to

the operator.

Once the protective cover is installed, swing the gate to

ensure that it does not contact the cover at any point of

the swing.

Re-engage the operator by inserting the key in the locking

cap (see Figure 3) and turning it clockwise until snug.

Remove the key.