B) correct! (a) wrong – Controlled Products Systems Group 1042001 User Manual

Page 10

Page 10

December, 2003

422 Operator And

455 D Control Panel Installation Manual

Before reinstalling the locking cap, you must be sure

that the top of the brass key assembly in the locking

cap is flush with the top of the black plastic locking cap

(see Figure 7). If the key assembly is not flush, turn the

locking cap assembly over and press down on the unit

until the brass key assembly snaps back into place.

WARNING!

If the brass key assembly is not

properly seated in the locking cap assembly,

you risk damaging, even eliminating, the

Manual Release function of the operator.

Next, reinstall the locking cap (without the key) with

your 3 mm hex key and the two screws.

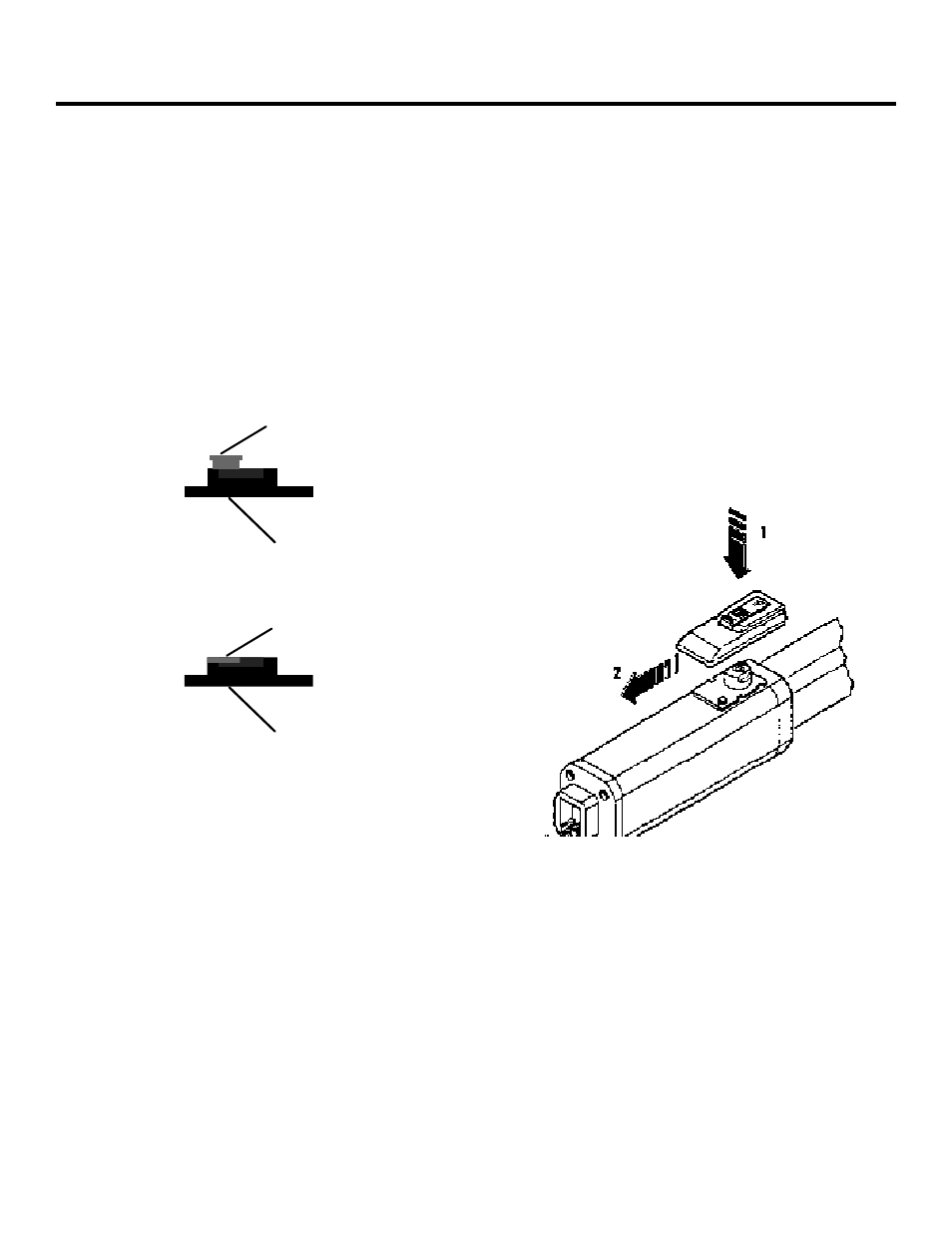

Now you can install the locking cap cover as shown in

Figure 8. Snap the cover on before you attempt to slide

the entire cover in the direction of the arrow. If the

cover does not snap into place, you are unable to slide

the cover into position.

Brass key assembly

Black plastic locking

cap assembly

Brass key assembly

Black plastic locking

cap assembly

(b) Correct!

(a) Wrong!

Figure 7. The brass key assembly in relation to the black

plastic locking cap, side view: (a) do not install in this

orientation and (b) install the locking cap only when the top

of the brass key assembly is flush with the black plastic

housing of the locking cap assembly.

Figure 8. Install the locking cap cover

B

LEED

THE

O

PERATOR

Air bubbles in hydraulic fluid cause erratic performance

in a hydraulic system, so you must rid the 422 Operator

of that air to insure smooth operation.

If you have removed the vent screw, the 422 operator

should bleed itself. Running the operator should remove

any air from the system. If the operator runs smooth

throughout the swing, no attempt to further bleed the

unit is necessary.

If the operator runs erratic, perform 10 bleeding opera-

tions. One bleeding operation consists of automatically

opening and closing the gate and then pausing for two

minutes. The 2-min pause allows the air bubbles to es-

cape through the vent screw hole.