Cashco DA8 Differential User Manual

Page 11

IOM-DA8/9

11

10. Evenly tighten the body bolting (11,12) in an

alternating cross pattern in one revolution

increments to the following torque value:

If supplied, remove pressure of previous Step 14.

G. Units with Supported Diaphragm Designs:

1. With composition diaphragm construction,

a supported diaphragm (9) construction is

des ig nat ed as Opt-81 High Inlet Pressure, and

comes with the highest range spring se lec tion

for sizes 2" and smaller.

H. Converting Internal/External Sensing:

1. Disassemble the regulator and remove the

diaphragm(s) (9) according to Steps 1-12 in

Part B – Main Regulator Disassembly.

2. To convert from internal to external sensing,

remove the drilled pipe plug (32) and install

a solid pipe plug. Reverse this step for con-

vert ing from external to internal sensing.

3. Reassemble the regulator according to Part

F – Main Regulator Reassembly.

I. Pressure

Testing:

1. If a hydrostatic pressure test is per formed,

pressure must be applied to all three of spring

chamber, inlet and outlet of body at the same

level.

2. Inboard Leakage Test (Seat + Dy nam ic Seal

Leakage).

a. Determine test pressure. If upper value

of range spring is less than 55 psig, use

test pressure of 5 psig less than upper

value of range spring. If upper value of

range spring is greater than 55 psig, use

test pressure of 50 psig.

b. While

applying

GN

2

or air pres sur iza tion

fl uid, engage adjusting screw inwards

until valve appears to be closed. Add one

additional revolution in wards to adjusting

screw.

c. Tube outlet to a beaker of water to ob serve

number of escaping gas bubbles.

3. Pressure Containment Test.

a. Pressurize inlet and outlet to 1.0 x Upper

Value of Range Spring or 30 psig with air

or GN

2

, whichever is higher.

b. Soap solution test all external leak points;

plugged connections, diaphragm fl ange,

di a phragm bolting and spring chamber

vent open ing.

4. Excessive leakage will require disassembly,

examination of sealing elements, correction

of problem, reassembly and retesting. NOTE:

This valve is NOT a bubble-tight shutoff de-

vice. See DAG-TB, Table DAG-10 for leak age

classes.

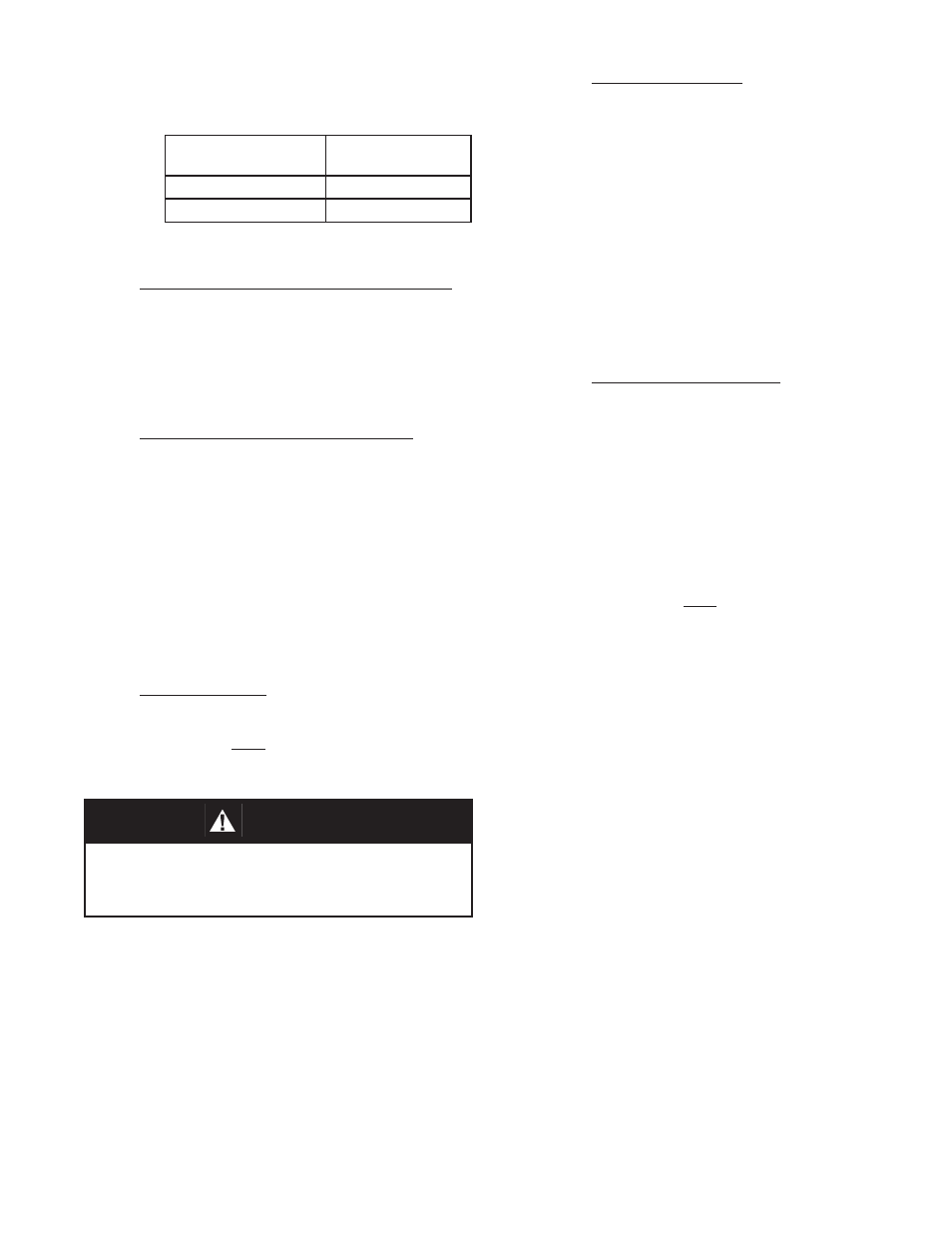

Body Size

in (mm)

Torque

ft-lb (N-m)

1/2" - 2" (DN15-50)

30-35 (41-47)

2 1/2" - 4" (DN65-100) 45-50 (61-69)

CAUTION

DO NOT HYDROSTATICALLY TEST WITHOUT SPRING

CHAMBER PRESSURIZED. NOT ADHERING WILL DO

PHYSICAL INTERNALS DAMAGE THAT COULD REN-

DER THE UNIT INOPERABLE.