Cashco 123-1+6+S User Manual

Page 5

IOM-123-1+6 +S DIFF

5

15. Using "NEW" studs (41,42) and nuts (8) (see

CAUTION D), thread one nut (8) onto each

stud (41,42) ap prox i mate ly 1.25" (32 mm).

Drop the studs (41,42) with nuts (8) through

holes in spring chamber (2). (This will assist

in keep ing the spring chamber (2) cen tered on

valve body (1) and prevent parts from moving

dur ing reassembly).

Using "match marks" made in Step B.4 as a

guide, replace spring chamber (2) onto body

(1). Thread lower nuts (8) onto studs (41,42)

and tight en by hand. Adjust length of studs

(41,42) by using the top nut (8) to allow at

least 3-4 threads protruding from the lower

nut (8).

Torque

body

fl ange hardware (7,8,30,41,42)

using small increments in a 180° alternating

pattern until fl ange mating sur fac es of body

(1) and spring cham ber (2) are metal to metal.

This creates a "fi xed com pres sion" on the

di a phragm (12) and o-ring seal (32). Rec om -

mend ed torque val ues are listed in Table 2.

fer en tial setting, check seat leak age at

40% below 15 psig (1.0 Barg); or 9 psig

(.62 Barg). Seat leak age should be min i-

mal (less than 20 SCFH). See SEC TION

VII-5. TROU BLE SHOOT ING GUIDE if

seat leakage is excessive.

2. Proof test to check for ex ter nal leakage.

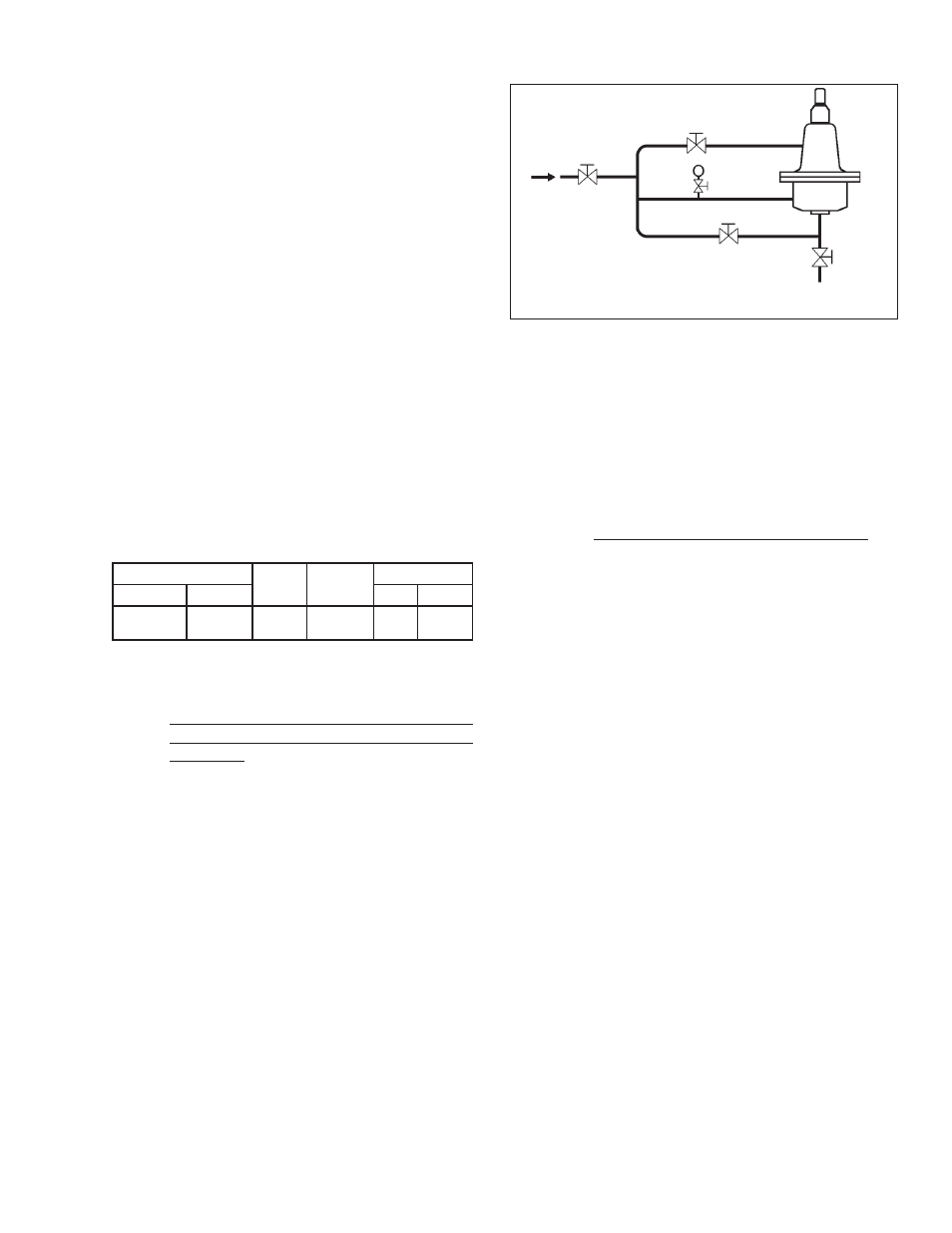

a. Close No. 1, No. 3, and No. 5 shut-off

valves. Open No. 2 and No. 4 shut-off

valves. Build inlet pressure to No. 1 shut-

off valve to 1-1/2 times maximum inlet

pressure, but not to exceed 1-1/2 times

Maximum Pres sure Rating (See Table

1).

b. Crack open No.1 shut-off valve and allow

a pressure buildup simultaneously in the

body (1) and spring chamber (2). Spray

the entire regulator with a liquid leak

de tec tor and visually inspect for external

leakage. Repair unit if leak is detected.

See SECTION VI MAINTENANCE.

c. Shut off line pressure to No. 1 shut-off

valve. Open No. 3 shut-off valve to re-

lieve all pressure from the test valve and

all shut-off valves.

3. Return to Section II for Installation and Sec-

tion IV for Startup.

TABLE 2

D. Bench test for suitable operation (Test Fluid:

Air or compressed gas).

1. Check for desired differential spring set ting

and regulator performance (with no loading

pressure):

a. Close No. 1, No. 2, and No. 4 shut-off

valves. Open No. 3 and No. 5 shut-off

valves.

b. Apply inlet (P

1

) pressure to No. 1 shut-off

valve (10-15 psig (.69-1.0 Barg) above

desired differential spring setting). Crack

open No. 1 shut-off valve and check for

valve opening at desired differential set-

ting. Refer to SECTION IV-2. if range

spring (18) adjustment is required.

c. Check for performance. NOTE: A metal

seat will experience a slight seat leak-

age). Seat leakage should be quantifi ed

at 40% deviation from setpoint. For

ex am ple: For a 15 psid (1.0 Bard) dif-

No. 1

Shut-off

Valve

No. 2

Shut-off

Valve

Pressure

Gauge

No. 3

Shut-off

Valve

Inlet P

1

Pressure

Outlet P

2

Pressure

No. 5 Isolation Valve

No. 4

Shut-off

Valve

Figure 2:

Recommended Bench Test

Piping Schematic for 123-1+6+S

BODY SIZE

ITEM

NO.

THREAD

SIZE

TORQUE VALUE

in

(DN)

Ft-lbs

(N-m)

1/2" - 1-1/2"

(15-40)

7, 8, 30,

41, 42

7/16-20

32-36

(43-49)