Cashco SAP User Manual

Page 7

IOM-SAP

7

SECTION VIII

VIII. TROUBLE SHOOTING GUIDE

When trouble shooting this regulator there are many possibilities as to what may be causing problems. Many

times, the regulator itself is not defective, but one or more of the accessories may be. Sometimes the pro cess

may be causing diffi culties.

The key to effi cient trouble shooting is information and communication. The customer should try to be as precise

as possible in their explanation of the problem, as well as their understanding of the application and operating

con di tions.

It is imperative the following information be provided by the customer:

Fluid

(with

fl uid properties)

Range

of

fl ow rate

Range of inlet pressure

Range of outlet pressure

Range

of

fl uid temperature

Range of ambient temperature

Pressure readings should be taken at every location that pressure plays a role - i.e., regulator inlet (as close as

possible to inlet port), regulator outlet (as close as possible to outlet port), etc.

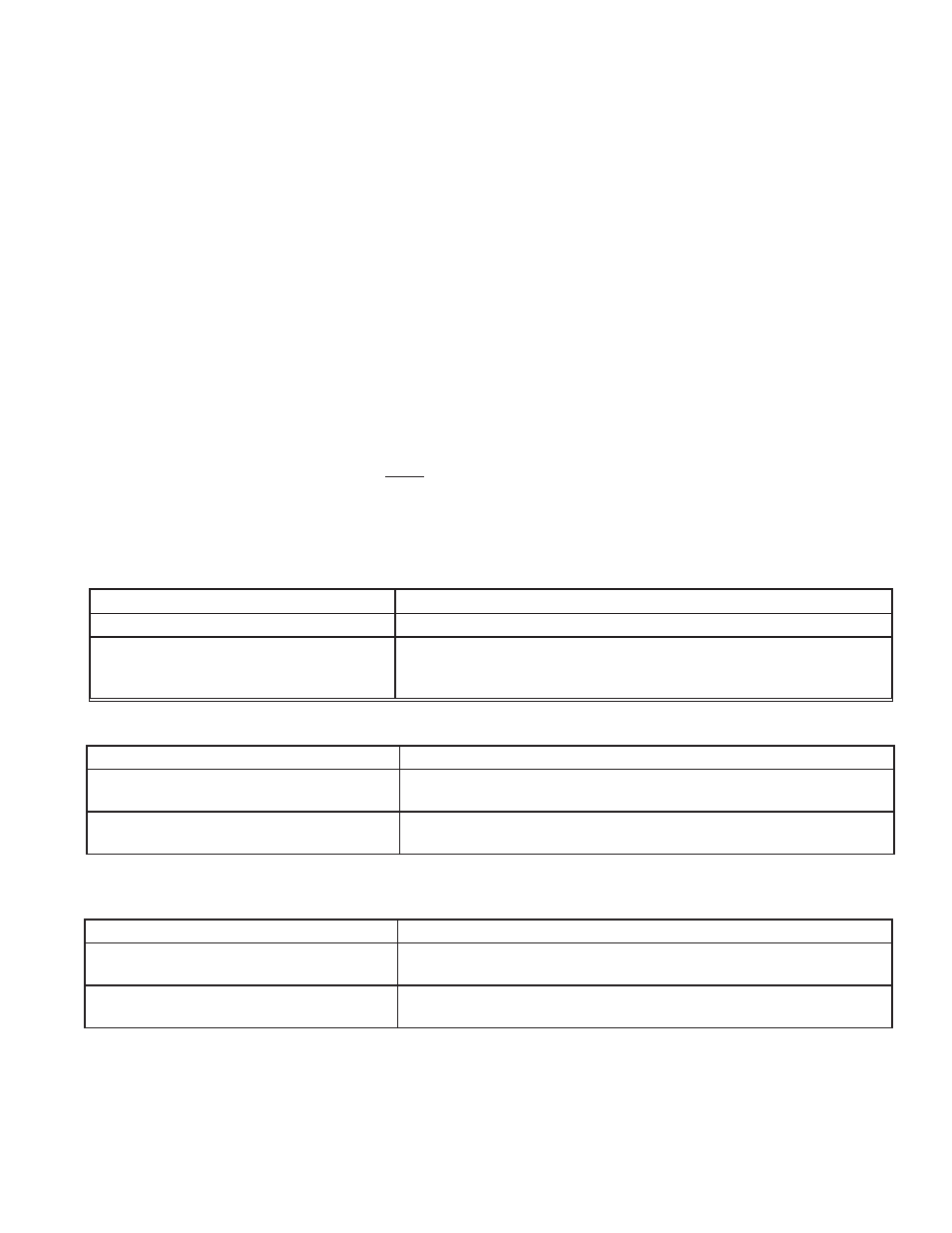

Below are some of the more common complaints along with possible causes and remedies.

Possible Causes

Remedies

A. Sticking of internal parts

A. Remove internals, clean, and if necessary, replace.

B. Oversized regulator

B. Check actual fl ow conditions; resize regulator for min i mum

and maximum fl ow; if necessary, replace with smaller

regulator.

1.

Erratic regulation, instability or hunting.

Possible Causes

Remedies

A. Supply pressure is down (confi irm

on pressure gauge).

A. Increase supply pressure

B. Undersized regulator.

B. Check actual fl ow conditions; resize regulator for minimum

and maximum fl ow; if necessary, replace with larger regulator.

2.

Downstream pressure will not reach desired setting.

Possible Causes

Remedies

A. Body bolts not torqued properly.

A1. Torque to proper value (see Section VII, C. 11.)

A2. Failed C-ring seal. Replace seal.

B. Pressures may be too

high for regulator design.

B. Consult factory.

3.

Leakage at fl ange.