Cashco P5 User Manual

Page 3

IOM-P5

3

SECTION VI

VI. MAINTENANCE

To prevent damage to body, use soft jaws when

placing body in a vise. Position so that vise closes

over the fl ats on lower end of body.

5

SPRING UNDER COMPRESSION. Prior to re mov ing

spring chamber, relieve range spring com pres sion

by turn ing knob (4) CCW until ro ta tion comes to a

com plete stop. Fail ure to so so may result in fl ying

parts that could cause personal injury.

WARNING

CAUTION

A. General:

1. Maintenance procedures hereinafter are based

upon re mov al of the regulator unit from the pipe-

line where in stalled.

2. Owner should refer to owner's procedures for

removal, handling, cleaning and disposal of

non reuseable parts, i.e. gaskets, etc.

3. Refer to Figure 2 for Model P5 basic reg u -

la tor and Figure 1 for the piston subassembly.

B. Piston Replacement:

1. Securely install the body (1) in a vise with the

knob (4) directed upwards.

2. Relax range spring (15) by turning knob (4)

CCW until rotation comes to a complete stop.

NOTE: It is not necessary to remove the knob

before removing the spring chamber (6) from

the body (1).

3. Remove spring chamber (6) by grasping the

fl ats and turning CCW. Upon removal, the

range spring (15), range spring clip (16), and

spring button (5) should remain inside the spring

cham ber. Remove pusher plate (18).

4. Remove snap ring (7) from piston.

5. Lift piston (14) out of body (1) and remove back-

up ring (19) and piston o-ring (20). Remove

body gas ket (10).

6. Clean body (1) according to owner's proce-

dures. NOTE: On reg u la tors origi nally sup plied

as “oxygen clean”, Option-M, main tenance

must in clude a level of clean li ness equal to

Cash co's clean ing stan dard #S-1134. Contact

factory for details.

7. Inspect and replace any necessary parts.

Use only parts man u fac tured and supplied by

Cashco, Inc. for these products. See Section

VIII.

8. Place the gas ket (10) onto the body (1) fl ange.

Use o-ring lube on o-ring (20) and slide o-ring

and back-up ring (19) on piston (14). Place

piston sub as sem bly into the body (1).

9. Install snap ring (7) above piston assembly.

Position pusher plate (18) on top of piston post.

10. Lubricate the threads of the body (1) with a

light weight grease that is compatible with ser-

vice use. Ro tate the spring chamber (6) CW by

hand onto the threaded portion of the body (1)

until fi rmly seated against the body gasket (10).

Tighten to the fol low ing torque val ue: 65–70 Ft

lbs (88–95 Nm).

11. Pressurize with air and spray liquid leak de tec-

tor around body (1) and spring chamber (6) to

test for leakage. En sure that an outlet pres sure

is main tained during this leak test of at least mid-

range spring level; i.e. 2-100 psig (.14-6.9 Barg)

range spring, 51 psig (3.5 Barg) test pres sure

min i mum.

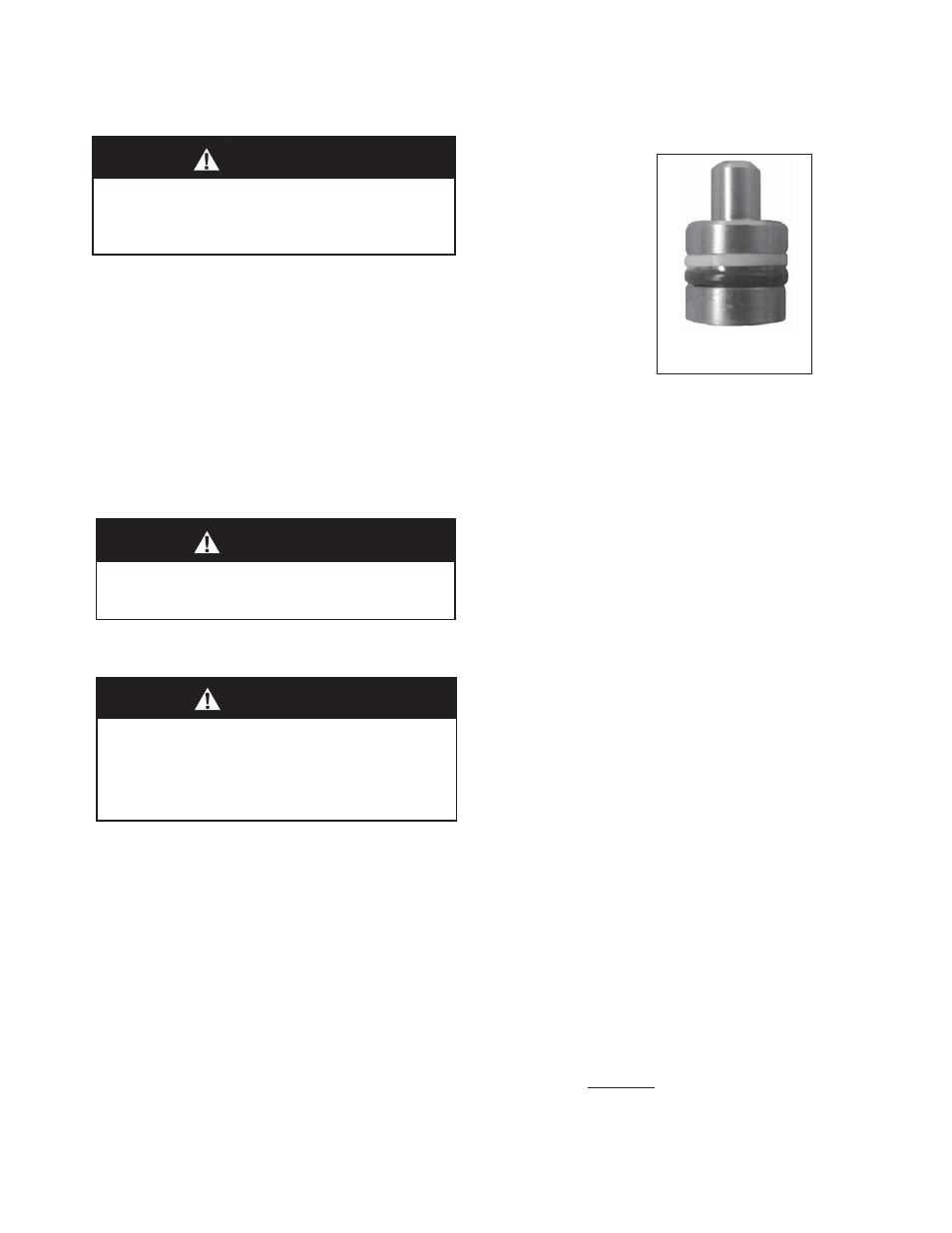

Figure 1:

Piston Subassembly

WARNING

SYSTEM UN DER PRES SURE. Prior to per form ing

any maintenance, isolate the reg u la tor from the

sys tem and relieve all pres sure. Failure to do so

could result in personal injury.