Cashco DA1 User Manual

Page 11

11

IOM-DA1

9. Metal Diaphragm Designs:

a. Install new diaphragm gasket (37) onto

body (23) diaphragm fl ange.

b. Position diaphragm(s) (9) onto body's

(23) diaphragm fl ange with bolt holes

aligned.

c. Position upper diaphragm pressure plate

(8) onto center top of diaphragm(s) (9)

with hub upwards.

10. Place a small amount of heavy grease into

the adjusting screw (1) threaded opening of

spring chamber (4). Reengage both adjust-

ing screw (1) and its lock nut (2) with spring

chamber (4). Allow end of adjusting screw to

protrude into interior approximately 1/2 inch

(12 mm).

11. Place range spring (6) centered on upper

di a phragm pressure plate (8).

12. Place a dab of heavy grease in the recess of

the spring follower (5). Place spring follower

on upper end of range spring (6).

13. Aligning matchmarks and bolt holes, place

spring chamber (4) over range spring (6). If

spring chamber (4) fl ange reaches body (23)

fl ange without a gap, remove and lower ad-

just ing screw (1) deeper into spring chamber

(4) cavity another 1/4 inch. Repeat this pro-

ce dure until the adjusting screw (1) keeps the

two fl anges form touching by approximately

1/8 inch (3 mm). NOTE: For metal diaphragm

con struc tion, if fl ang es do not come to geth er

equal ly, the upper di a phragm pres sure plate

(8) may be off-center. Remove spring cham ber

(4) and reposition upper di a phragm pres sure

plate (8) until the spring chamber (4) comes

down evenly on all sides.

14. Reinstall

all

fl ange bolts (11) and nuts (12) with

nameplate (99) located under one bolthead.

Hand-tighten nuts (12).

NOTE: If a six-ply diaphragm is being used,

it is important that the diaphragm (9) is “pre-

formed” – pulled together to remove as much

entrapped air as possible and allow formation

of a diaphragm (9) convolution. Starting with

the body bolts and nuts (11,12) hand tight ened,

“preforming” can be accomplished by any one

of the following techniques:

a. Relax range spring fully by rotating

ad just ing screw CCW.

b. Apply 30 psig (2.1 Barg) pressure to the

valve outlet.

OR

Block the valve outlet and apply 30 psig

(2.1 Barg) under the di a phragm through

the 1/4" NPT (plugged) external pres-

sure sens ing connection on the valve

diaphragm fl ange.

c. Leave pressure on through tightening

of bolt ing (11,12).

15. Evenly tighten the body bolting (11,12) in an

alternating cross pattern in one revolution

increments to the following torque value:

If supplied, remove pressure of previous

Step 14.

G. Units with Supported Diaphragm Designs:

1. A supported diaphragm (9) construction is

designated as Opt-80 High Outlet Pressure.

2. For a Model DA1 the only “special” part to be

supplied is the spring chamber (4). This spring

chamber (4) includes a machined ledge to

support the diaphragm upon overpressure,

and prevent a bust.

H. Converting Internal/External Sensing:

1. Disassemble the regulator and remove the

diaphragm(s) (9) according to Steps 1-12 in

Part B – Main Regulator Disassembly.

2. To convert from internal to external sensing,

remove the drilled pipe plug (32) and install

a solid pipe plug. Reverse this step for con-

vert ing from external to internal sensing.

3. Reassemble the regulator according to Part

F – Main Regulator Reassembly.

I. Pressure

Testing:

1. If a hydrostatic pressure test is performed,

pressure must be applied uniformly through out

the regulator. In particular apply the same

pressure to body inlet, body outlet, and spring

chamber.

DO NOT HYDROSTATICALLY TEST WITH-

OUT SPRING CHAMBER PRESSURIZED.

NOT ADHERING WILL DO PHYSICAL IN-

TERNALS DAMAGE THAT COULD REN DER

THE UNIT INOPERABLE.

2. Inboard Leakage Test.

a. Release all range spring force by backing

out adjusting screw fully.

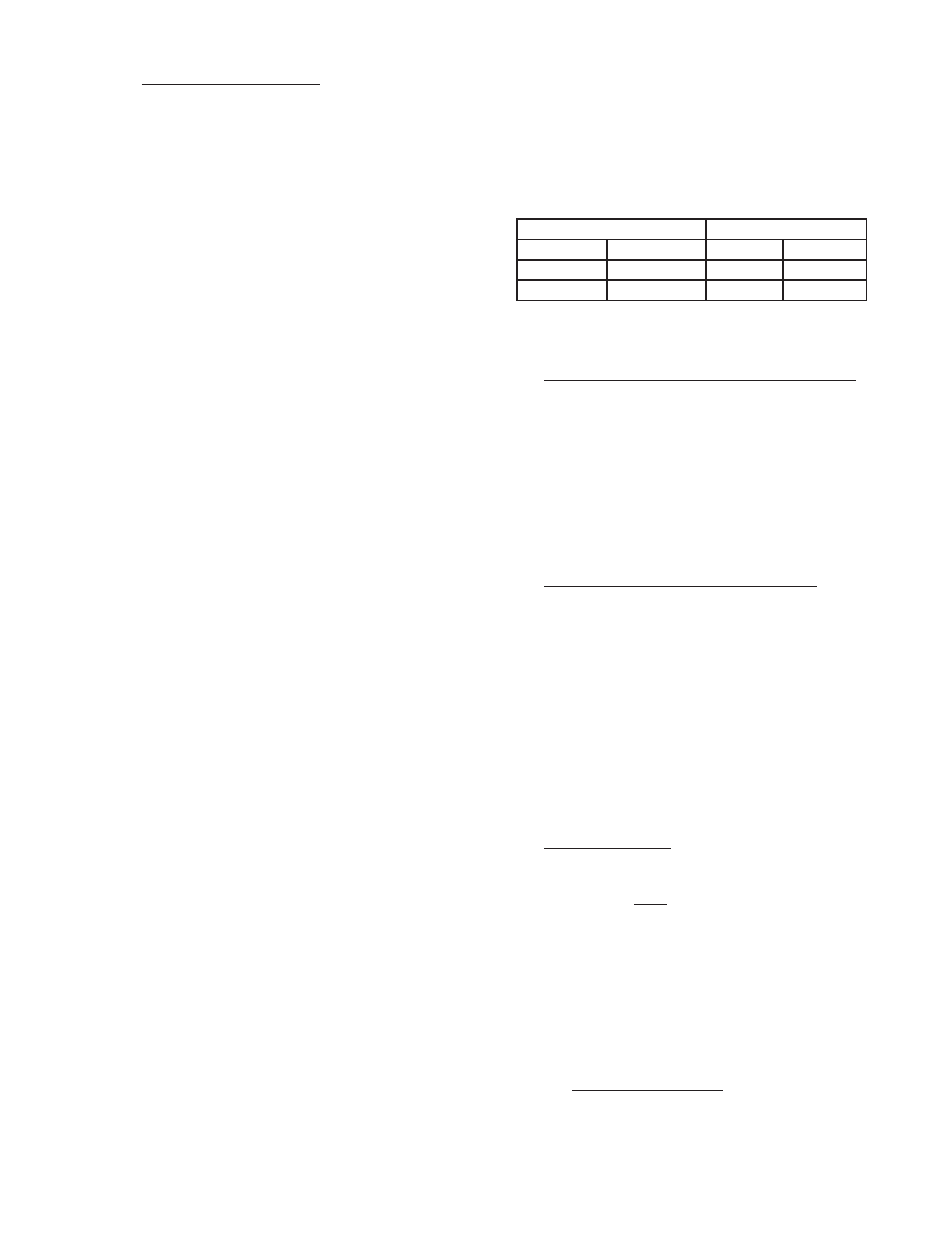

Body Size

Torque

in

(mm)

ft-lbs.

(Nm)

1/2"-2"

(DN15-50)

30-35

(41-47)

2 1/2"-4"

(DN65-100)

45-50

(61-69)