Cashco 1465 User Manual

Page 5

IOM-1465

5

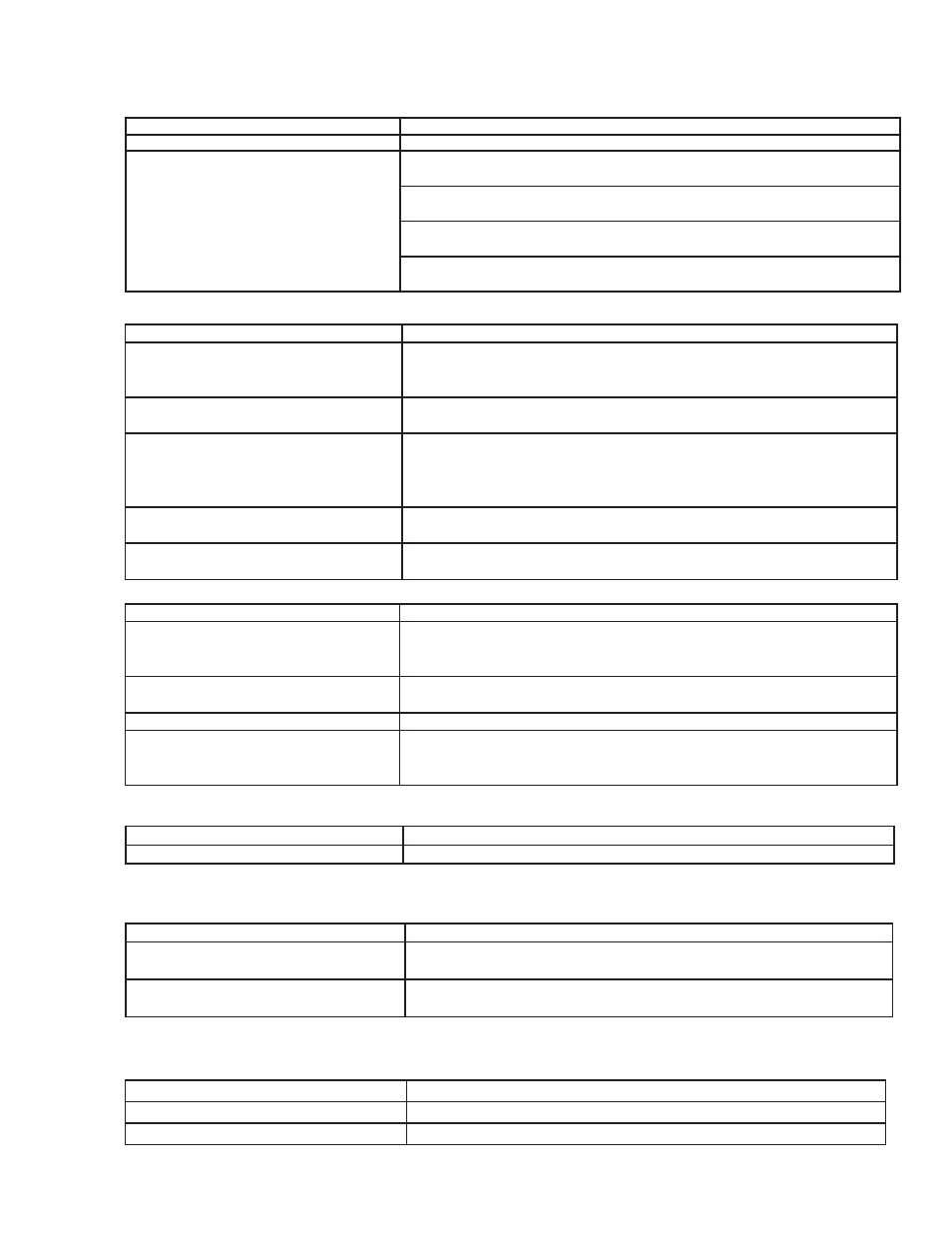

5. Sluggish operation.

2. Leakage through the spring chamber vent hole.

3. Regulator can't pass suffi cient fl ow.

4. Excessive pressure downstream.

6. Excessive seat leakage.

7. Leakage out of threaded connection between body and spring chamber.

Possible Causes

Remedies

A. Normal-life diaphragm failure.

A. Replace diaphragm

B. Abnormal short-life diaphragm

failure.

B1. Can be caused by excessive chattering. See No. 1 to remedy

chatter.

B2. Can be caused by corrosive action. Consider alternate diaphragm

material.

B3. For composition diaphragms, ensure not subjecting to over-

temperature conditions.

B4. Downstream (outlet) pressure buildup occurring that overstresses

diaphragms. Relocate regulator or protect with safety relief valve.

Possible Causes

Remedies

A. Regulator undersized.

A1. Confi rm by opening bypass valve together with regulator.

A2. Check actual fl ow conditions, re-size regulator; if regulator

has inadequate capacity, replace with larger unit.

B. Plugged trim.

B. Remove regulator from line and check for debris in inlet

connection.

C. Incorrect range spring(screwing in

CW of adjsting screw

does not allow bringing pressure

level up to proper level).

C. Replace range spring with proper higher range. Contact factory.

D. Too much droop

D1. Review droop expected.

D2. Contact factory.

E. Cavitation

E. Use multiple 1465's in series to stage the pressure drops. Refer

to 1465 Technical Bulletin for water cavitation chart.

Possible Causes

Remedies

A. Regulator not closing tightly.

A. Inspect the seating. Check tht plug (3), plug spring (4), and spring

seat (5) are centered in body (1) cavity. Replace regulator should

these steps not remedy.

B. Downstream block.

B. Check system; isolate (block) fl ow at regulator inlet - not outlet.

Relocate regulator if necessary.

C. No pressure relief protection.

C. Install safety relief valve or rupture disc.

D. Restricted diaphragm movement.

D. Ensure no moisture in spring chamber at temperatures below

freeze point. Ensure no dust or debris entering vent opening. If

rainwater or debris enter, re-orient regulator.

Possible Causes

Remedies

A. Fluid too viscous.

A. Heat fl uid. Contact factory

Possible Causes

Remedies

A. Foreign matter on seating surface,

erosion of seating surface.

A. Inspect and clean seat. If seat eroded, replace regulator.

B. Cavitation

B. Use multiple 1465's in series to stage pressure drops. Refer to

1465 Technical Bulletin for water cavitation chart.

Possible Causes

Remedies

A. Insuffi cient spring chamber torque.

A. Tighten spring chamber on body using suffi cient torque.

B. Damaged o-ring

B. Replace o-ring.