Oil level gauge – Gardner Bender 1 1_8 HP Titan Pumps User Manual

Page 4

■

INSTALLATION (continued)

■

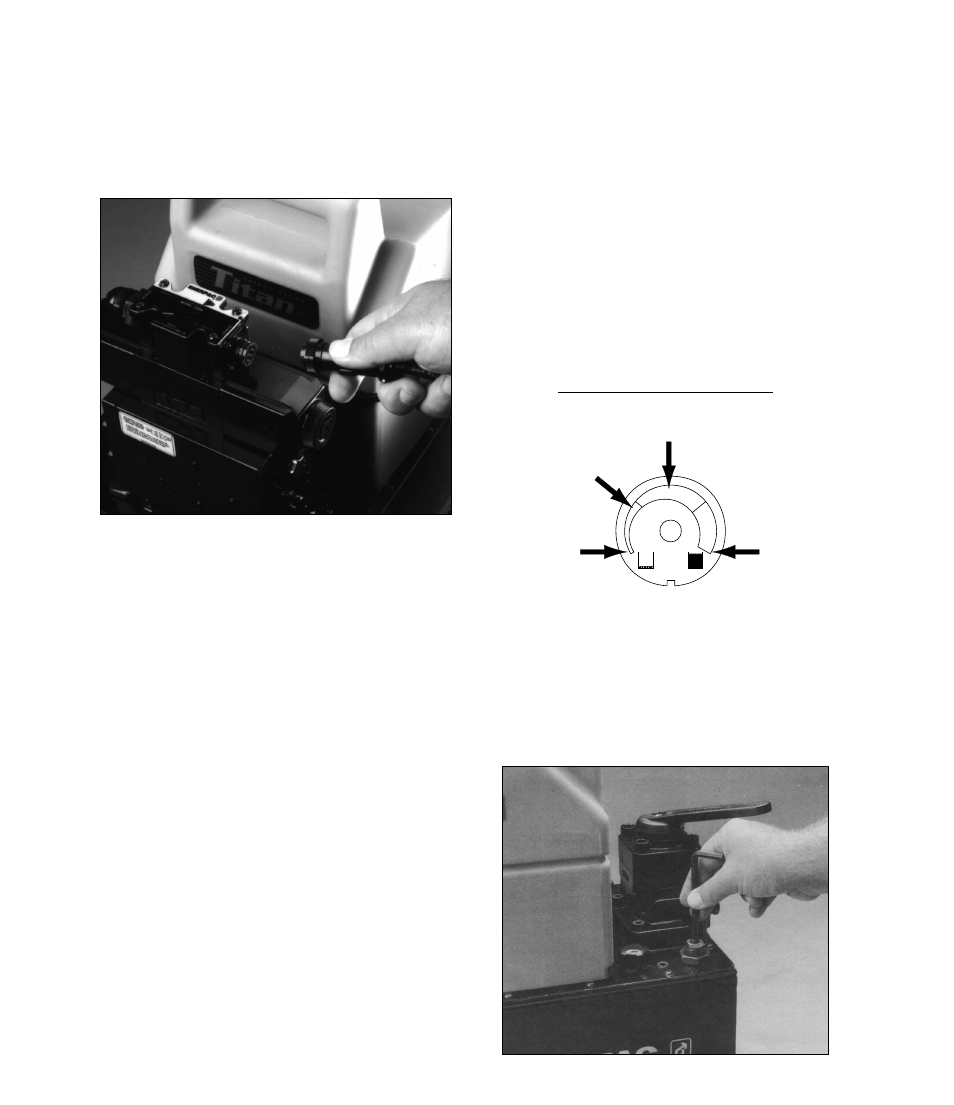

Attached Control Switch

If your pump has a solenoid valve, attach a

solenoid valve pendant or foot switch to control the

valve using the connector as shown.

Set the Relief Valve (if necessary)

The external relief valve is located under a hex cap

on top of the pump. It is adjustable from 10,000 psi

(700 bar) down to 2000 psi (140 bar). Operating

pressure cannot be adjusted to above 10,000 psi

(700 bar).

To get the most accurate relief valve setting, start at

a lower pressure and adjust up to the desired relief

valve setting.

1. Install a pressure gauge in the pump outlet port.

2. Remove the hex cap covering the relief valve

adjustment screw. Loosen locknut. Using an allen

wrench, turn the adjustment screw counter-

clockwise one full turn.

3. Turn the pump on and run the pump motor,

watching the pressure gauge reading. Stop the

pump and adjust the relief setting until it is at the

desired pressure.

4. Verify the setting by running the pump several

times.

5. Tighten lock nut to secure setting on relief valve.

6. Replace the hex cap to cover the adjusting

screw.

■

Check Oil Level

Check the oil level prior to start-up and add GB

Electrical Hydraulic Oil, If necessary. Remove

the oil level gauge and add oil through the

opening in the top of the reservoir.

IMPORTANT: Add oil only when all system

components are in the fully retracted position. If

oil is added when plungers are advanced, there

will be more oil in the system than the pump

can hold. When cylinders are retracted, oil in

the hoses and cylinders will be returned and

the reservoir will be over filled.

Be sure to monitor oil level while pump

is running. If the oil level is full before

running the pump, but becomes low

during operation, the reservoir is too

small for your application.

Empty

Full

Add

Oil

In Use

OIL LEVEL GAUGE

4