Gardner Bender B2000 Series G-OLD Cyclone Bender User Manual

3 offset bending, 4 stub-up bending, Table a

10. To bend more conduit of the same material and at the

same angle, load and secure as described in steps 3

through 6. To bend the same type conduit but at a different

angle, load and secure; turn angle indicator to the desired

angle, then press toggle to bend.

11. Bending different type and size conduit requires repeating

steps 2 through 10.

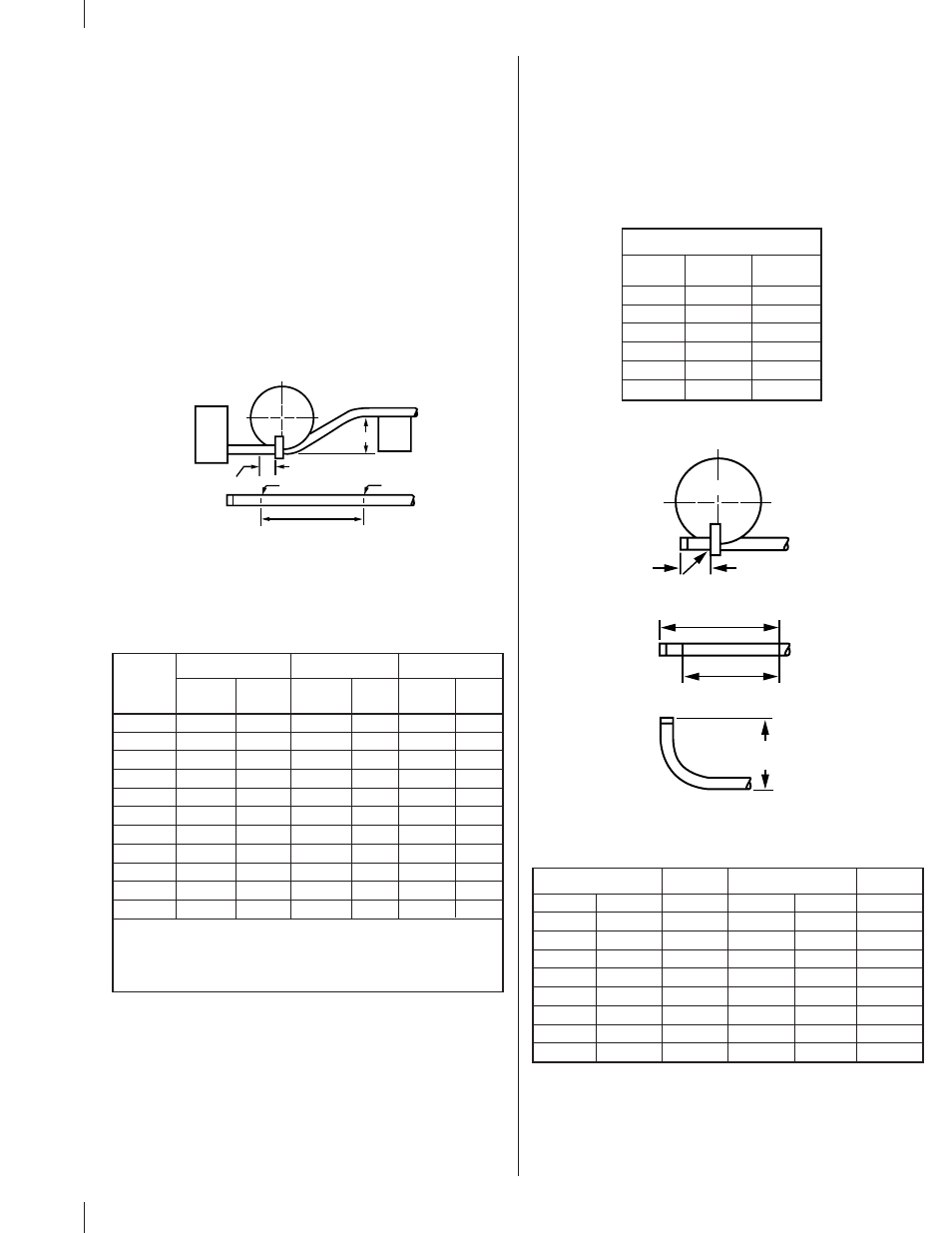

4.3 Offset Bending

1.

Obtain distance “M" from table A, and measure this

distance from mark #1 and place mark #2.

2.

Now place mark #1 in line with front edge of shoe clamp

and make first bend.

3.

Next rotate conduit 180° level, place mark #2 in

line with front edge of shoe clamp and make

second bend.

NOTE: When bending rigid aluminum, set bend angle indicator

approximately 4° short of desired angle, since aluminum does

not have spring-back of steel.

4.4 Stub-up Bending

1.

Table C shows minimum length (inches).

2.

Mark #1 is stub length, deduct from this as per table C

and obtain mark #2.

Offset

Beam

Box

M

Front Edge of Clamp

See Table A

Min. 2"

Mark #2

Mark #1

5

Offset

Conduit

Conduit

Conduit

Required

Max. Size

M

Max. Size

M

Max. Size

M

2”

3

⁄

4

”

7

3

⁄

4

”

4”

1

1

⁄

2

”

15

7

⁄

16

”

3

⁄

4

”

8”

6”

2”

23

3

⁄

16

”

1”

12”

1

⁄

2

”

8

1

⁄

2

”

8”

30

5

⁄

8

”

1

1

⁄

2

”

16”

1”

11

5

⁄

16

”

10”

38

5

⁄

8

”

2”

20”

1

1

⁄

4

”

14

1

⁄

8

”

12”

46

3

⁄

8

”

24”

1

1

⁄

2

”

16

15

⁄

16

”

14”

54

1

⁄

16

”

28”

2”

19

13

⁄

16

”

16”

61

13

⁄

16

”

32”

22

5

⁄

8

”

18”

67

7

⁄

16

”

36”

25

7

⁄

16

”

20”

77

1

⁄

4

”

40”

28

1

⁄

4

”

22”

85”

44”

31

1

⁄

8

”

To locate distance between centers of offset bending marks other than listed in

table A use the following multipliers:

15˚ bend - 3.9

30˚ bend - 2.0

45˚ bend - 1.4

Table A

15˚ Bend

30˚ Bend

45˚ Bend

Conduit

Radius

Radius

Size

Rigid / IMC

EMT

1

⁄

2

”

3

31

⁄

32

”

3

7

⁄

8

”

3

⁄

4

”

4

25

⁄

32

”

4

29

⁄

32

”

1”

5

9

⁄

16

”

5

29

⁄

32

”

1

1

⁄

4

”

6

7

⁄

8

”

7

3

⁄

32

”

1

1

⁄

2

”

7

9

⁄

16

”

7

1

⁄

2

”

2”

8

9

⁄

32

”

8

9

⁄

16

”

Table B

BEND RADIUS

1

⁄

2

”

Rigid

7

3

⁄

4

”

1

1

⁄

4

”

Rigid

12

3

⁄

4

”

1

⁄

2

”

IMC

7

3

⁄

4

”

1

1

⁄

4

”

IMC

12

1

⁄

2

”

1

⁄

2

”

EMT

7

5

⁄

8

”

1

1

⁄

4

”

EMT

13”

3

⁄

4

”

Rigid

9”

1

1

⁄

2

”

Rigid

13

1

⁄

2

”

3

⁄

4

”

IMC

9”

1

1

⁄

2

”

IMC

13

1

⁄

2

”

3

⁄

4

”

EMT

8

1

⁄

2

”

1

1

⁄

2

”

EMT

13

1

⁄

2

”

1”

Rigid

10

1

⁄

8

”

2”

Rigid

15

3

⁄

4

”

1”

IMC

10

1

⁄

8

”

2”

IMC

15

1

⁄

2

”

1”

EMT

10

3

⁄

8

”

2”

EMT

15

1

⁄

2

”

Table C

Conduit

Stub-up

Conduit

Stub-up

Size

Set-back

Size

Set-back

Shoe

Min. 2˝

Stub Length

Set Back

Mark #2

Mark #1

Front Edge of

Clamp Mark #2

Stub to Bottom

of Pipe