Gardner Bender B2555 Series Electric Sidewinder Bender User Manual

Page 8

8

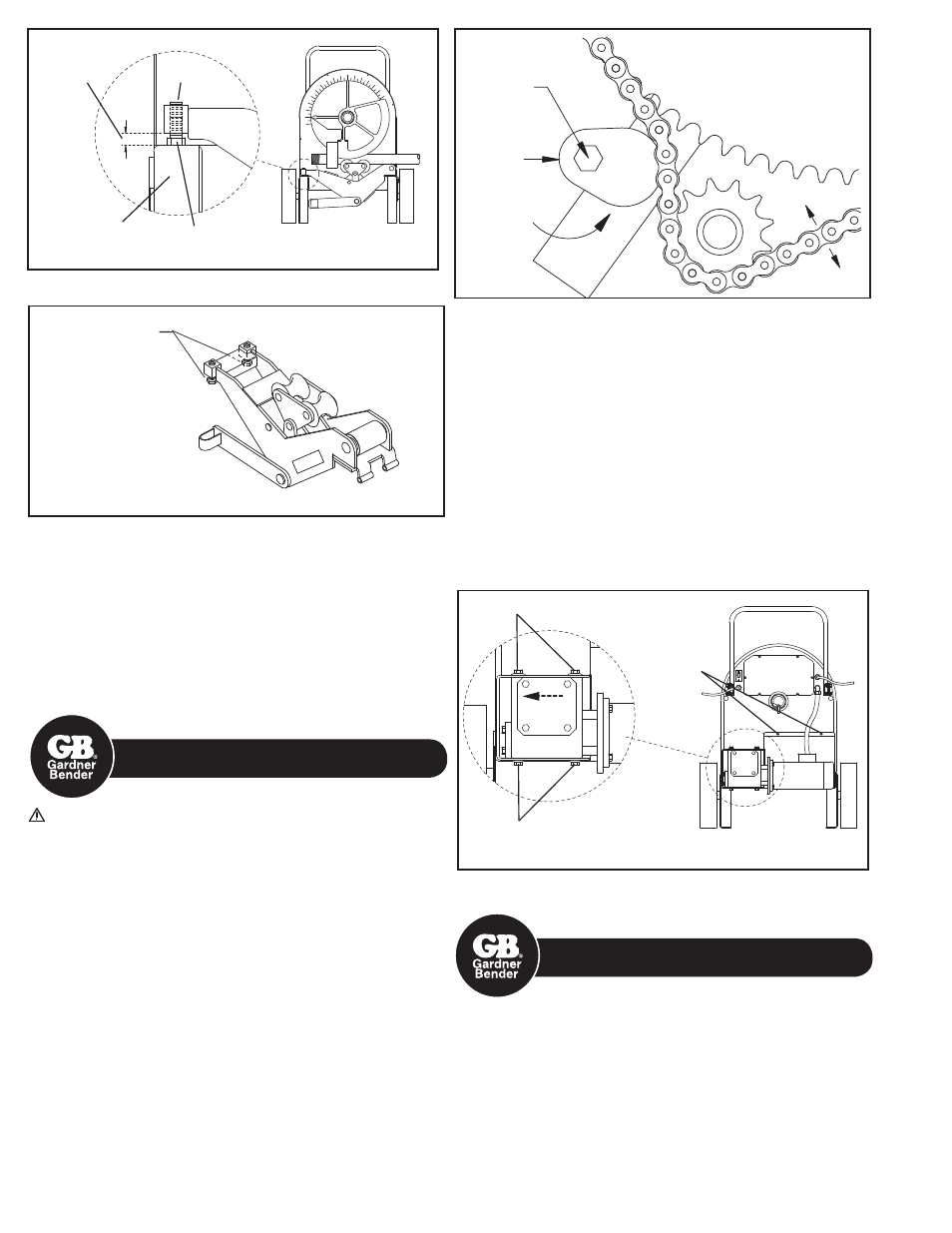

2. If side marking occurs, or loading IMC or EMT is a problem,

pressure against the conduit during the bending process must

be decreased. To decrease the squeeze ( pressure ), loosen

both set screws and turn both adjusting bolts one-half turn

counter-clockwise. Tighten both set screws and bend one piece

of conduit to test the adjustment. If side marking still occurs,

repeat the procedure.

NOTE: Both adjusting bolts MUST be in contact with the bender

frame.

15.0 MAINTENANCE

WARNING: ALWAYS disconnect power supply before removing

any guards or covers and before servicing this bender. Failure to

do so may result in serious injury or death.

1. The Gear Box is filled with oil at the factory and should not

require periodic flushing. If the Gear Box is opened for repair,

flush by filling the unit with an AGMA #7 oil. Next, run the unit

with no load for 3 minutes. Then, drain and refill the unit with 28

fluid ounces of an AGMA #7 oil such as the ones listed below.

Amoco – Amoco Worm Gear Oil

Chevron – Cylinder Oil 460X

Exxon – CYLESSTIC TK460

Mobil – 600 W Cylinder Oil

Shell – Sun Gear Oil 7C

2. To inspect FRONT #60 chain tension:

• Remove front cover plate.

• To adjust, loosen hex bolt with 3/4 wrench and rotate chain

tensioner toward chain as shown until chain moves no more

than a total of 1/4". See Figure 16.

• Grease chain periodically with a good quality MP grease.

Figure 15

Both Adjusting

Bolts Must Contact

Bender Frame

3. To inspect REAR #40 chain tension:

• Check chain tension after an initial break-in period of 2 - 3 hours

of use and tighten per the instructions below. See Figure 17.

Thereafter, inspect monthly.

• Remove the chain guard by taking out the 2 mounting screws.

• Loosen 8 bolts ( 4 on top and 4 on bottom ) that hold the gear

box in position.

• To tighten chain, move the gear box to the left and

re-tighten bolts.

• For correct tension, chain should deflect approximately 1/8".

NOTE: Be sure to keep the gear box and motor in line with

the bender.

• Grease chain periodically with a good quality MP grease.

16.0 STUB-UP BENDING

INFORMATION AND CHARTS

To locate bending marks and springback of 15, 30, 45, 60, and 90

degree bends for a desired stub:

1. Check Chart A, B, or C for deduct length. Note that minimum stub

length is deduct length plus 2".

2. Measure and mark desired stub length on conduit ( stub length

mark ). Subtract “Deduct Length” from this mark and make

a second mark ( bending mark ). See Fig 18a and 18b. Place

bending mark at front edge of shoe hook. See Figure 18c.

Check Chart A, B, or C for springback of desired degree of

bend. Bender should be advanced to this degree to obtain

desired degree of bend.

To Tighten

Chain

Figure 17

4 Bolts on

Bottom

4 Bolts on Top

Chain Guard

Mounting

Screens

Bender Leg

Figure 14

1/2"

Adjusting

Bolt

Set

Screw

Starting

Location of

Adjusting

Bolt

Rotate Chain

Tensioner Upward

to Tighten Chain

Figure 16

1/4" Max

Hex Screw

Chain

Tensioner