Gardner Bender B2555 Series Electric Sidewinder Bender User Manual

Page 6

6

COULD result in minor personal injury or property damage.

10.0 MOUNTING SUPPORT

ROLLERS & SUPPORT UNITS

Choose the desired support unit for corresponding shoe size

and type ( RIGID, IMC, EMT, or 40 mil PVC coated RIGID ). The

appropriate size and type of support unit MUST be used with the

corresponding shoe size and type.

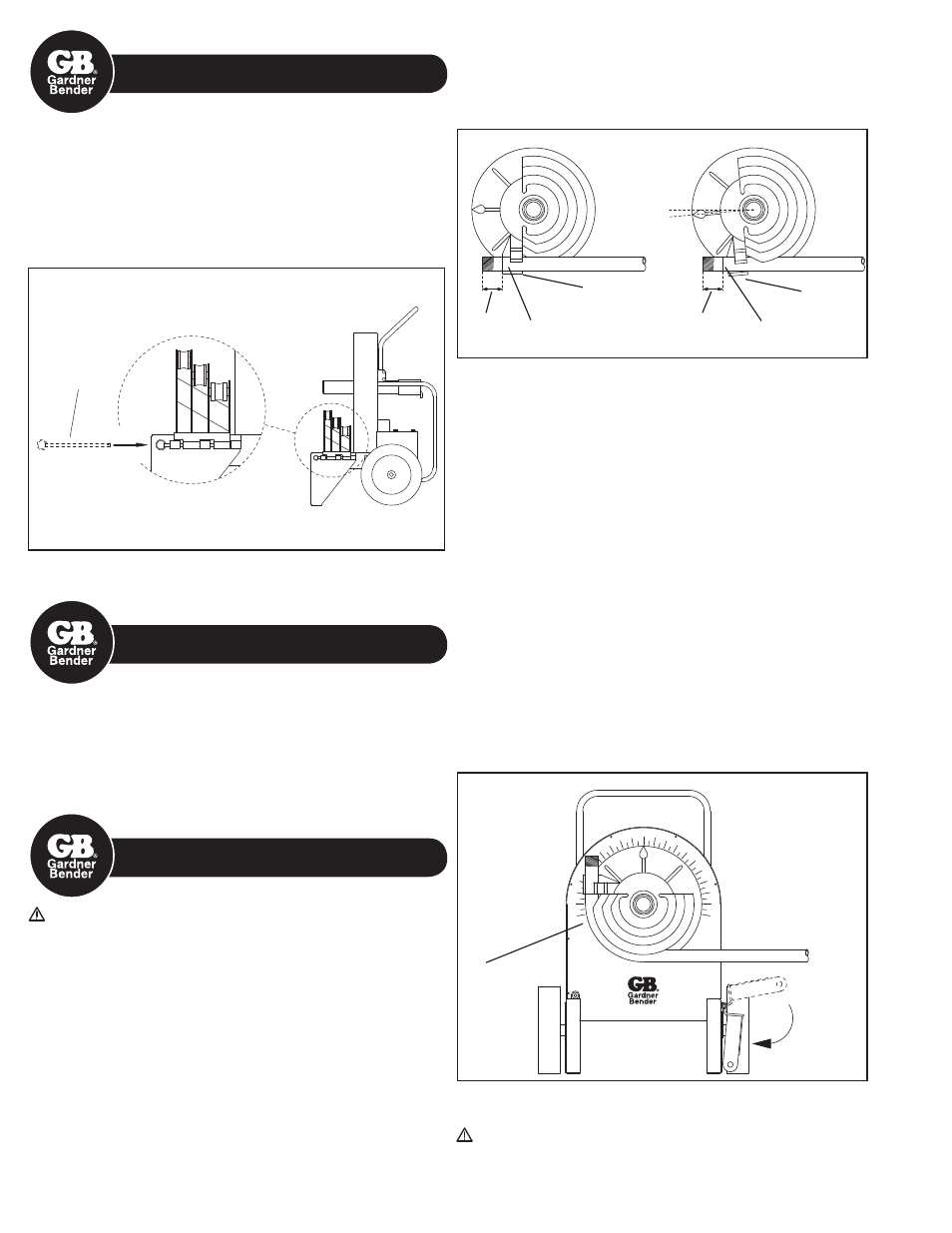

Mount the support unit on the right leg of the bender as you face the

unit. Secure the support unit with the quick release hinge pin. See

Figure 7.

Quick

Release

Hinge Pin

Figure 7

11.0 Mounting Instructions for

Greenlee

®

Shoes and Attachments

Bending shoes and attachment from Greenlee

®

555

®

and 555

Classic

®

R, E, I ( RIGID, EMT, IMC ) and 40 mil PVC coated RIGID

benders with serial number PL and AAJ will fit the B2555 bender.

All B2555 bending shoes and attachments will fit Greenlee

®

555

®

R, E, I benders with PL and AAJ serial numbers.

* Greenlee

®

555

®

and 555 Classic

®

are registered trademarks of Greenlee/Textron.

12.0 GENERAL BENDING

INSTRUCTIONS

DANGER: NEVER operate this bender in an explosive

atmosphere. Injury or Death may occur.

Bending instructions for:

1/2" thru 2" RIGID conduit

1/2" thru 1-1/4" EMT conduit

1/2" thru 1-1/4" IMC conduit

1/2" thru 2" 40 mil PVC coated RIGID conduit

1/2" thru 2" schedule 40 pipe

See pages 5 and 6 for mounting shoes and support units. Be sure to

match the appropriate shoe with its corresponding support unit.

1. Mark pipe/conduit to desired length. Note that a minimum of

2" from the end of the conduit to the front edge of the hook is

required to eliminate flattening the end of the pipe/conduit. See

Figure 8a.

NOTE: Stub-up and Offset Dimensions can be found on the

Bending Charts on pages 8 thru 10 of this manual or on the bending

instructions decal on top of each bender.

2. Rotate the bending shoe 5 to 10 degrees below the 0 ( zero )

degree setting, as shown in Figure 8b below.

3. After marking the pipe/conduit, place it into the bender. See Figure

8a. The pipe/conduit should slide over the correct size support

unit, through the shoe groove and into the hook. The bending

mark should be at the front ( OUTSIDE ) edge of the hook. See

Figure 8a.

4. Using the remote hand unit ( pendant ), place the “Bend/Unload”

switch in the “bend” position. Press the “Jog” button and advance

the bender. Be sure to check the alignment of the bending mark

as the rotating shoe locks the pipe/conduit into position. Advance

the bender shoe to desired degree of bend. When the pointer on

the shoe reaches the desired degree of bend, release the “Jog”

button and the bender will stop. See Figure 9.

NOTE: Due to springback in pipe/conduit, some over bending is

necessary to achieve the desired degree of bend. See page 9 or

the bending instruction decal on top of each bender for approximate

springback compensation figures.

5. To release the pipe/conduit, place the “Bend/Unload” switch in

the “Unload” position. Press the “Jog” button and reverse the

shoe far enough to release the conduit. Then, rotate the support

unit out of the way. See Figure 9. The pipe/conduit can now be

removed.

WARNING: The pipe/conduit should be under control when

unloading. Failure to do this may result in injury or death.

2"

minimum

Figure 8a

Figure 8b

Bending

Mark

Hook

0°

5°

Bending

Mark

Hook

2"

Minimum

90° Bend

Shown

Figure 9

Rotate