Procedure – Fluid Components International ST110_ST112_STP110_STP112 VeriCal User Manual

Page 5

ST100 Series VeriCal Operation Manual

Fluid Components International LLC

3

Procedure

• Verify that the VeriCal pressure gauge indicates 25.0 PSIG (+/- 0.20 PSIG). Note: using the exact pressure levels allows one to compare the cur-

rent findings to the FCI Factory findings and any subsequent findings.

• Allow the instrument to stabilize by sustaining the pressure for a minimum of 5 minutes. Observing the flow and temperature reading stability

on the ST100 Configurator to verify that the instrument has come to equilibrium.

• Record the VeriCal pressure as indicated on the regulator assembly pressure indicator and the ST100 data that is shown on the Configurator:

RefR, dR, TCdR, Temperature, Flowrate and optionally the output current across a precision 250Ω resistor.

• Repeat this process for 50, 75 and 100 PSIG pressures.

• The recorded values are the instrument’s in-situ baseline calibration readings. All future verification readings will be compared to these baseline

values and should be within 2-5% of the Field Baseline Data readings.

• It is advisable to complete one more round of “Field Check Data” to establish a pattern of repeatability for this specific combination.

Note: This step is not mandatory, but it will help to understand the VeriCal system and what can be expected for future verifications.

• The ST100 Configurator application can now be closed.

• Place probe assembly back into the correct location in the center of the process piping as indicated in the installation section of the operation

manual.

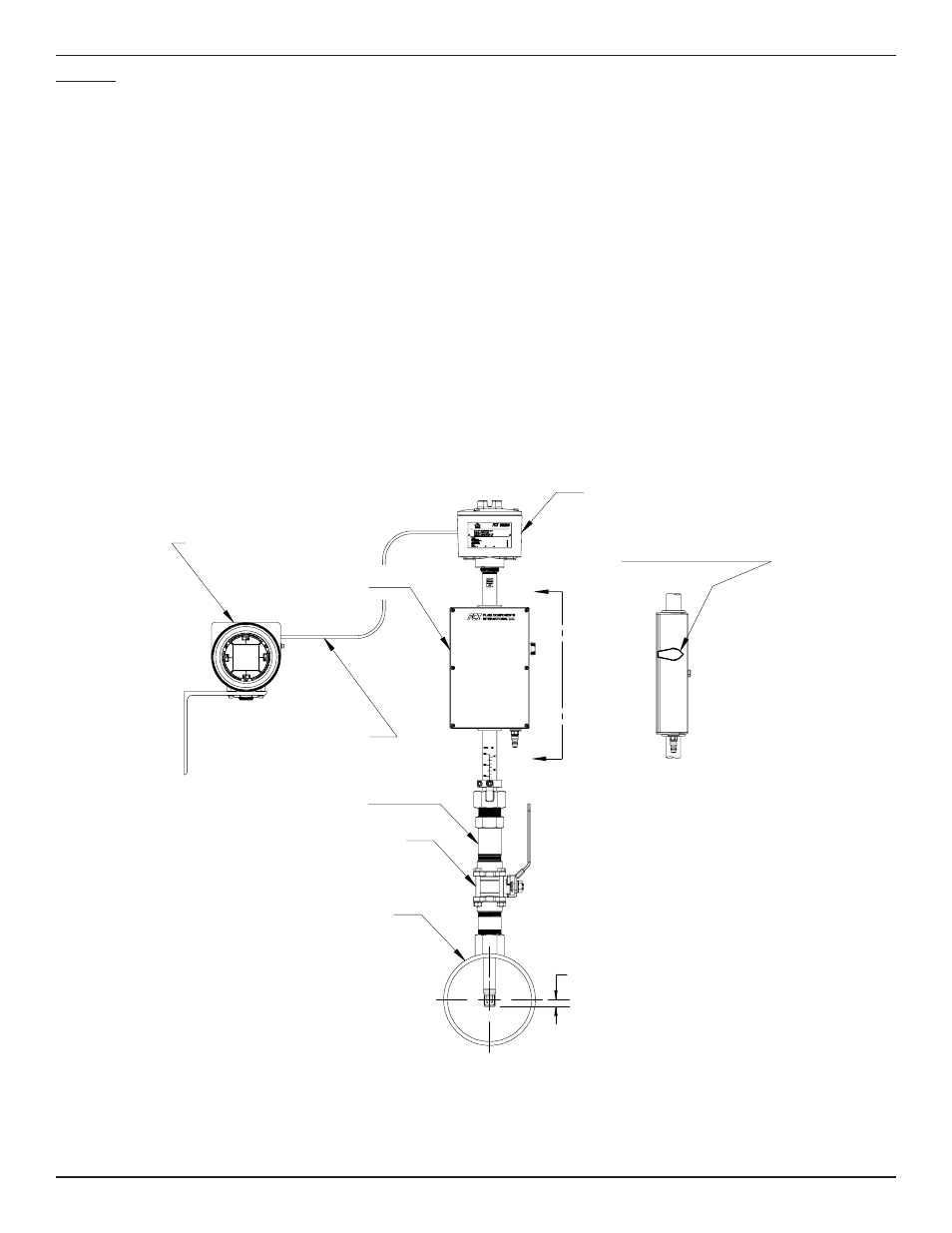

Normal Mounting Configuration

.50

A

A

OPEN

PLUG VALVE

(SHOWN IN CLOSE POSITION)

VIEW A-A

VERICAL BOX

ASSEMBLY

LOCAL ENCLOSURE

REMOTE

ENCLOSURE

(SYSTEM ELECTRONICS)

C01061-2-1

INTERCONNECTING

REMOTE CABLE

PACKING GLAND

ASSEMBLY WITH

1 1/4" NPT

BALL VALVE

PROCESS PIPING