Fluid Components International 8-66B_12-64B Series Manual Troubleshooting User Manual

Page 2

FLUID COMPONENTS INTL

CHAPTER 5 - TROUBLESHOOTING

Models 12-64/8-66 Basic Switch

5 - 2

Doc. No. 06EN003264 Rev. A

1.

Review the application design with plant operation personnel and plant engineers.

2.

Ensure that plant equipment such as pressure and temperature instruments conform to the actual conditions.

3.

Verify operating temperature, operating pressure, line size, and gas medium.

Verification of Sensing Element Resistance

The measurements are based on a standard (5K ohm RTD at 70°F, or 21°C) sensing element. Variation of

±

100

ohms from nominal is to be expected, depending on temperature. The maximum allowable difference in resistance

between matched RTD's is 1% at ambient temperature (immersed in water). The heater resistance should be 225

±5

ohms. Be sure to subtract the cable resistance to get the true resistance.

1.

Turn off the operating power to the instrument.

2.

Gently remove (pull straight out) the control circuit from the socket. Using a DMM, measure the resistance of

the active and reference RTD sensing elements and the heater as found in Table 5-1 to determine if the sensing

element is functional.

Note:

The resistance of the active RTD will be greater than the resistance of the reference RTD whenever the

heater is on.

If there is an indication of an open or short in the RTD, the sensing element will need to be replaced.

After replacing the sensing element, it will be necessary to follow the alarm set point adjustment procedures found in

the Operation Chapter before returning the instrument to service.

If the sensing element resistance is correct, proceed to the voltage verification test.

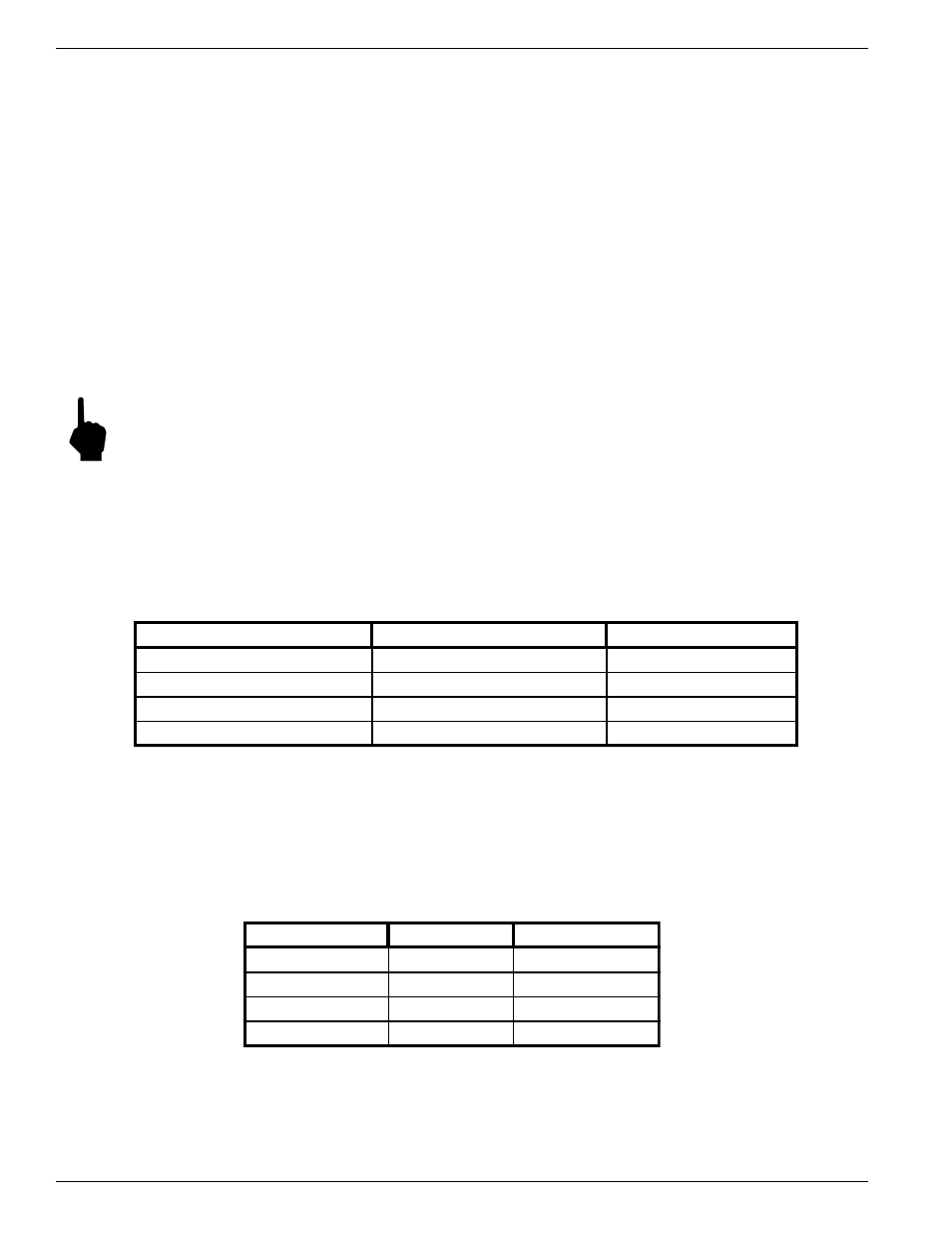

Table 5-1. Sensing Element Resistances In Ohms

*Resistance varies with temperature. These values should be

±

5 ohms at 70

°

F (21

°

C).

Verification of Sensing Element Voltage

If the above resistance checks are good, plug in the control circuit and apply power. Measure the voltages in

Table 5-2. If the voltages are not correct, then remove and replace the control circuit.

Table 5-2. Sensing Element Voltages

From Terminal Pin

To Terminal Pin

Voltage Expected**

9 (+)

7 (-)

22VDC

7 (+)

8 (-)

12VDC

9 (+)

8 (-)

10VDC

10 (+)

7 (-)

19VDC

**Voltages are dependent on temperature.

From Terminal (Pin)

To Terminal (Pin)

Expected Ohms*

Heater (7)

Heater (10)

225

Ref Sen (9)

Com Sen (8)

5000

Ref Sen (9)

Act Sen (7)

10000

Act Sen (7)

Com Sen (8)

5000