Burkert Type 6628 User Manual

Page 2

1.

OPERATING INSTRUCTIONS

The operating instructions contain important information.

• Read the instructions carefully and follow the safety instructions

in particular.

• Keep the instructions in a location where they are available to

every user.

• The liability and warranty for Type 6628 are void if the operating

instructions are not followed.

2.

INTENDED USE

The rocker solenoid valve Type 6628 is designed for analytical,

medical and laboratory applications. It is predominantly used to dose,

fill, mix, and distribute liquids and gases.

• Do not use Type 6628 outside without taking suitable protective

measures.

• Operate only when in perfect condition and pay attention to correct

storage, transportation, installation and operation.

2.1. Predictable Misuse

• Do not use Type 6628 in potentially explosive area.

• Do not make any internal or external changes to Type 6628.

3.

BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any contin-

gencies and events which may arise during installation, operation

and maintenance.

WARNING!

Danger – high pressure!

• Before loosening lines or valves, turn off the pressure and vent

the lines.

Risk of burns/risk of fire if used continuously through hot

device surface!

• Keep Type 6628 away from highly flammable substances and

media and do not touch with bare hands.

• Do not obstruct the heat release required for operation.

To prevent injury, ensure the following:

• Secure equipment/device from unintentional actuation.

• Only trained technicians may perform installation and mainte-

nance work.

• After an interruption in the power supply, ensure that the pro-

cess is restarted in a controlled manner.

• Observe the general regulations of technology.

Electrostatic sensitive components/modules!

Observe the requirements in accordance with EN 61340-5-1 and

5-2 to minimize/avoid the possibility of damage caused by a sudden

electrostatic discharge!

4.

TECHNICAL DATA

4.1. Operating Conditions

Permitted temperatures:

Diaphragm material Media and ambient temperature

FKM

0 ... +55 °C

FFKM

+10 ... +55 °C

EPDM

-10 ... +55 °C

Media: aggressive, neutral, gaseous and liquid media which do

not attack housing and seal materials. (Recommendation: See

.

Check that resistance is adequate in individual cases.

Protection class:

Rectangular plug IP40

Circular plug and wired connection IP65

4.2. Standards

The conformity with EC guidelines is guaranteed in accordance with

standards EN 61000-6-2, EN 61000-6-4.

4.3. Electrical Data

See type plate.

5.

INSTALLATION / DISASSEMBLY

5.1. Fluid Installation

WARNING!

Risk of injury from high pressure in the equipment.

• Before loosening lines or valves, turn off the pressure and vent

the lines.

Installation position: any position, preferably with actuator above.

→

Clean pipelines and flange connections.

→

Install dirt filter in the direction of flow in front of the valve (mesh

size 5 μm).

WARNING!

Risk of medium escaping if seal is seated incorrectly

• Make sure that the supplied seal fits properly.

• Use only connection plate of adequate quality and with a flat

surface.

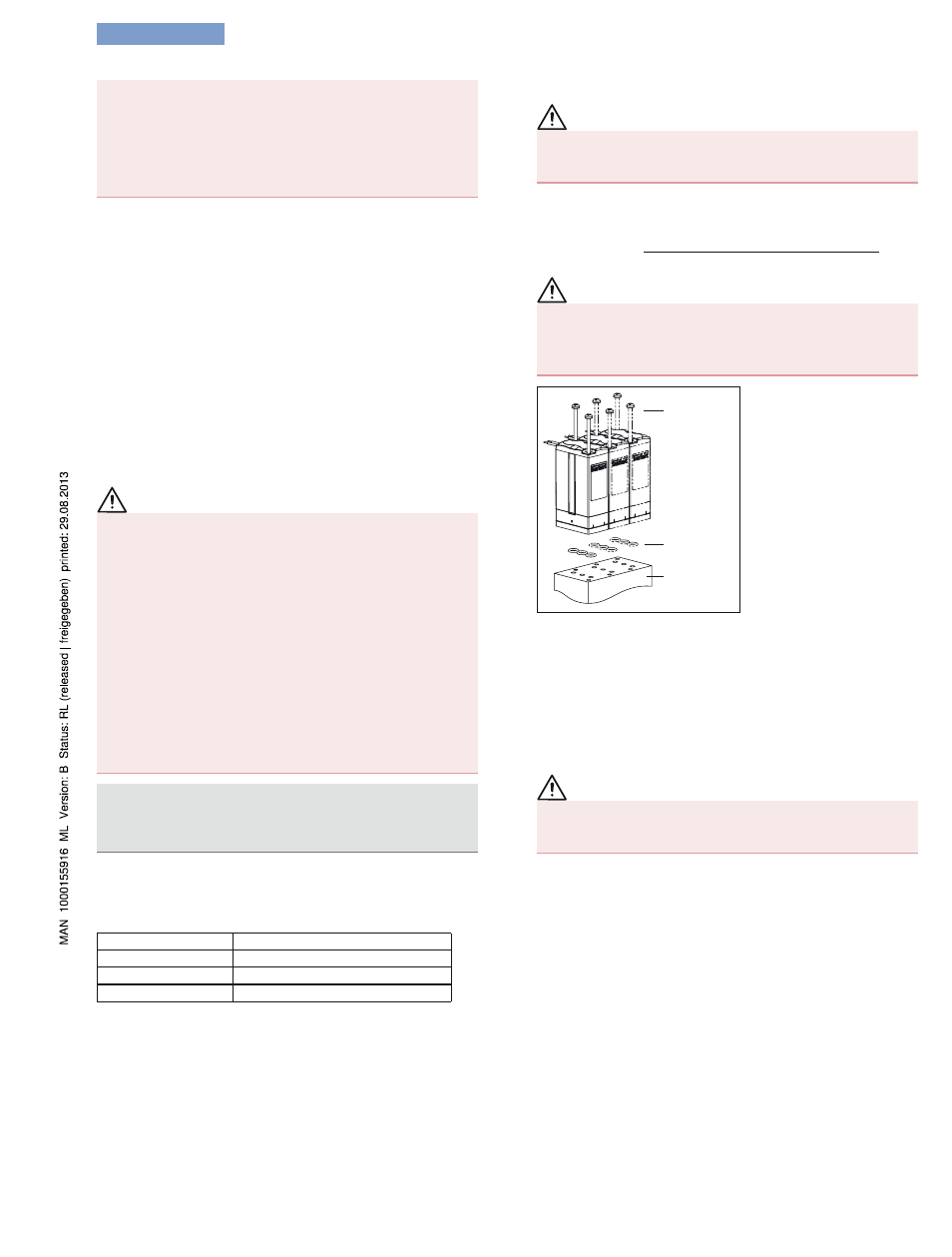

Screws

Seals

Connection

plate

→

Drill holes according to

drilling pattern

(dimensions see data

sheet).

→

Insert the seal into the

valve.

→

Correctly assign fluid

connection configuration

1, 2 and 3 on valve and

connection plate.

→

Attach valve.

→

Check installation for

leaks.

5.2. Electrical Installation

Electrical power supply:

Tolerance ± 10 %

Permissible residual ripple: Tolerance ± 10 % of the nominal

voltage

Power consumption:

5 W

5.3. Disassembly

WARNING!

Risk of injury from hazardous media.

• Before loosening lines or valves, flush out hazardous media,

depressurize and drain the lines.

6.

MAINTENANCE

Under normal operating conditions, the valve is maintenance-free.

7.

MALFUNCTIONS

If malfunctions occur, check

• that the fluid connections have been correctly assigned

according to the operating principles,

• whether the operating pressure is within the permitted range,

• the power supply and valve control

• the electric connections have the correct polarity.

•

8.

TRANSPORTATION, STORAGE, DISPOSAL

• Transport and store Type 6628 in shock-resistant packaging to

protect against moisture and dirt.

• Permitted storage temperature: -10 … +65 °C.

• Dispose of the device and packaging according to the appli-

cable disposal and environmental protection regulations.

Type 6628

english