Burkert Type 6281 User Manual

Page 4

8

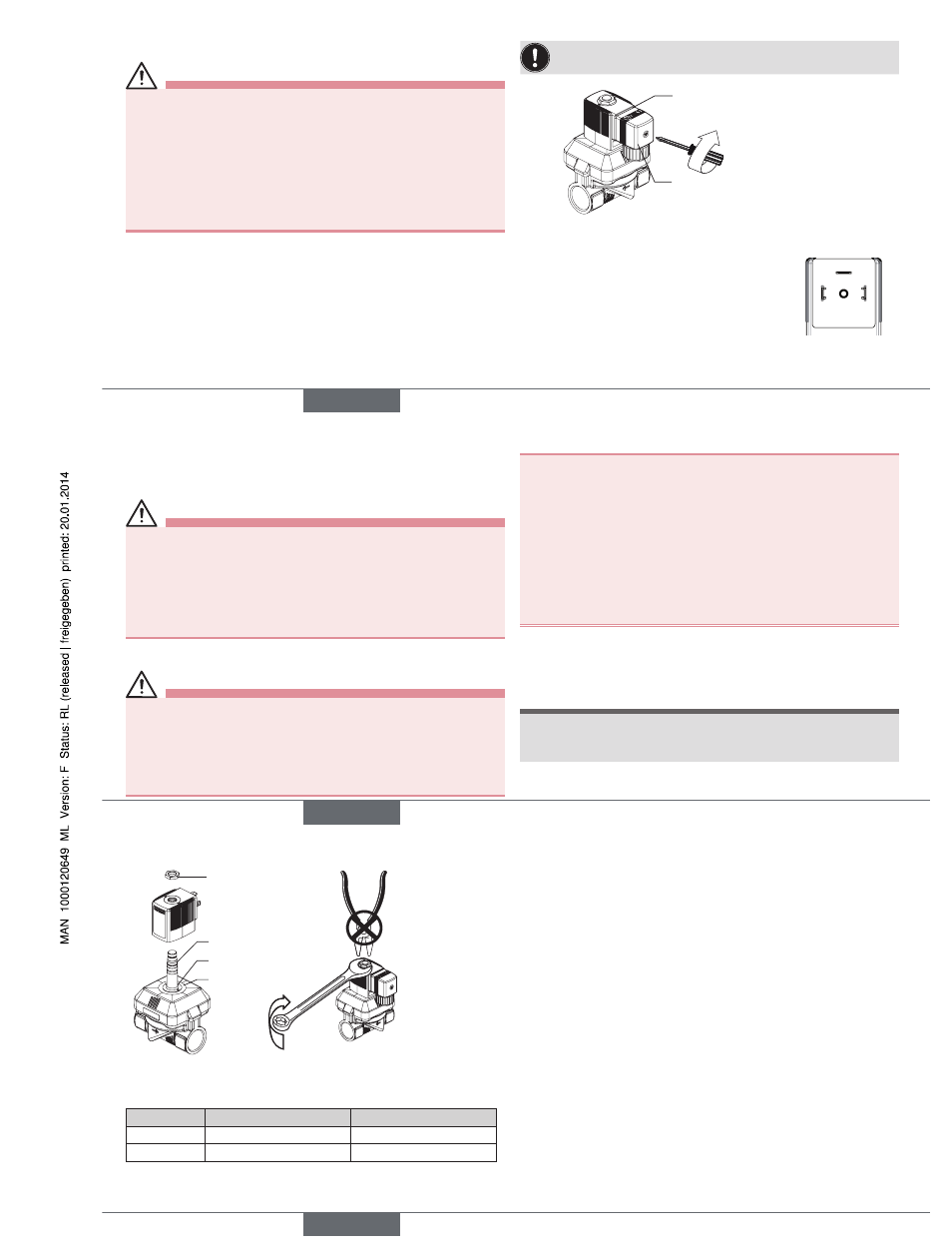

5.5 Electrical connection of the cable plug

Warning!

Risk of injury due to electrical shock!

▶ Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations for

electrical equipment!

If the protective conductor contact between the coil and body is

missing, there is danger of electrical shock!

▶ Always connect protective conductor.

▶ Check electrical continuity between coil and body.

Procedure:

→

Tighten cable plug (for permitted types see data sheet), observing

max. torque 1 Nm.

→

Check that seal is fitted correctly.

→

Connect protective conductor and check electrical continuity between

coil and body.

Note the voltage and current type as specified on the type label.

Authorized cable plug e.g. Type 2508

or other suitable cable plug in accor-

dance with DIN EN 175301-803

Form A

Seal

max. 1 Nm

Pulse version (optional, Code CF 16):

1

2

• Valve opens when current pulse min. 50 ms:

– on Pin 1, + on Pin 2

• Valve closes when current pulse min. 50 ms:

+ on Pin 1, – on Pin 2

english

9

6

MainTEnancE, TrOuBlEshOOTing

6.1 safety instructions

Warning!

Risk of injury from improper maintenance!

▶ Maintenance may be carried out by authorized technicians only and

with the appropriate tools!

Risk of injury from unintentional activation of the system and an

uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

6.2 installation of the coil

Warning!

Electric shock!

▶ Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

If the protective conductor contact between the coil and body is

missing, there is danger of electrical shock!

▶ Check protective conductor contact after installing the coil.

Escaping medium!

When a sticking nut is loosened, medium may escape.

▶ Do not tighten sticking nut any further.

Overheating, risk of fire!

Connection of the coil without pre-assembled valve will result in

overheating and destroy the coil.

▶ Connect the coil with pre-assembled valve only.

Danger due to electrical shock if coil incorrectly installed!

▶ During installation ensure that the coil is situated firmly on the body

cover so that the protective conductor connection of the coil is

connected to the valve body.

Procedure:

→

Connect coil body to the core guide pipe.

→

Screw on coil with nut. Observe torque.

note!

Device will be damaged if the wrong tools are used!

Always use a wrench to tighten nut. If other tools are used (e.g. pliers),

the device may be damaged.

→

Check protective conductor.

english

10

Observe

torque for fas-

tening nut!

(See table)

Nut

O-ring

Core guide pipe

Locking pin

Torque for fastening nut:

Coil type

Coil width

Torque [Nm]

AC10

32 mm resp. 40 mm

5 Nm

AC19

42 mm

10 Nm

6.3 Malfunctions

If malfunctions occur, check whether:

→

the device has been installed according to the instructions,

→

the electrical and fluid connections are correct,

→

the device is not damaged,

→

all screws have been tightened,

→

the voltage and pressure have been switched on,

→

the pipelines are clean.

Valve does not switch

Possible cause:

• Short circuit or coil interrupted,

• Core or core area dirty.

• Medium pressure outside the permitted pressure range.

Valve does not close

Possible cause:

• Internal space of the valve is dirty.

• Small control bore in the diaphragm blocked.

• Valve opened by manual control.

english

Type 6213 EV / 6281 EV