Burkert Type 6281 User Manual

Page 3

5

4.2 application conditions

Ambient temperature:

max. +55 °C

Operating duration:

Unless otherwise indicated on the type label,

the solenoid system is suitable for con-

tinuous operation

Important information for functional reliability during continuous

operation!

If standstill for a long period at least 1-2 activations per day are

recommended.

Service life:

High switching frequency and high pressures

reduce the service life

Permitted medium temperature depending on coil and seal material:

Coil body

PA/EP

1)

Seal material

Medium temperature

Polyamide PA

FKM

0 ... +90 °C

Epoxy EP (NA38)

FKM

0 ... +120 °C

Polyamide PA

EPDM

-30 ... +90 °C

Epoxy EP (NA38)

EPDM

-30 ... +100 °C

Polyamide PA

NBR

-10 ... +80 °C

1)

Marking PA and EP under electric connection

Permitted media depending on seal material:

Seal material

Permitted media

2)

FKM

Per-solutions, hot oils without additives, diesel

and heating oil without additives, detergent

solution

EPDM

Oil and grease-free liquids, cold and warm

water

NBR

Cold and warm water

2)

Gaseous media at low differential pressures (e.g. compressed air and vacuum)

can also be actuated in consideration (or due to restriction) of a lower tightness.

We recommend prior clarification with our sales office regarding the possible

application

4.3 conformity

In accordance with the EC Declaration of conformity, the solenoid valve

Type 6213 EV / 6281 EV is compliant with the EC Directives.

4.4 standards

The applied standards, which verify conformity with the EC Directives,

can be found on the EC Type Examination Certificate and / or the EC

Declaration of Conformity.

english

6

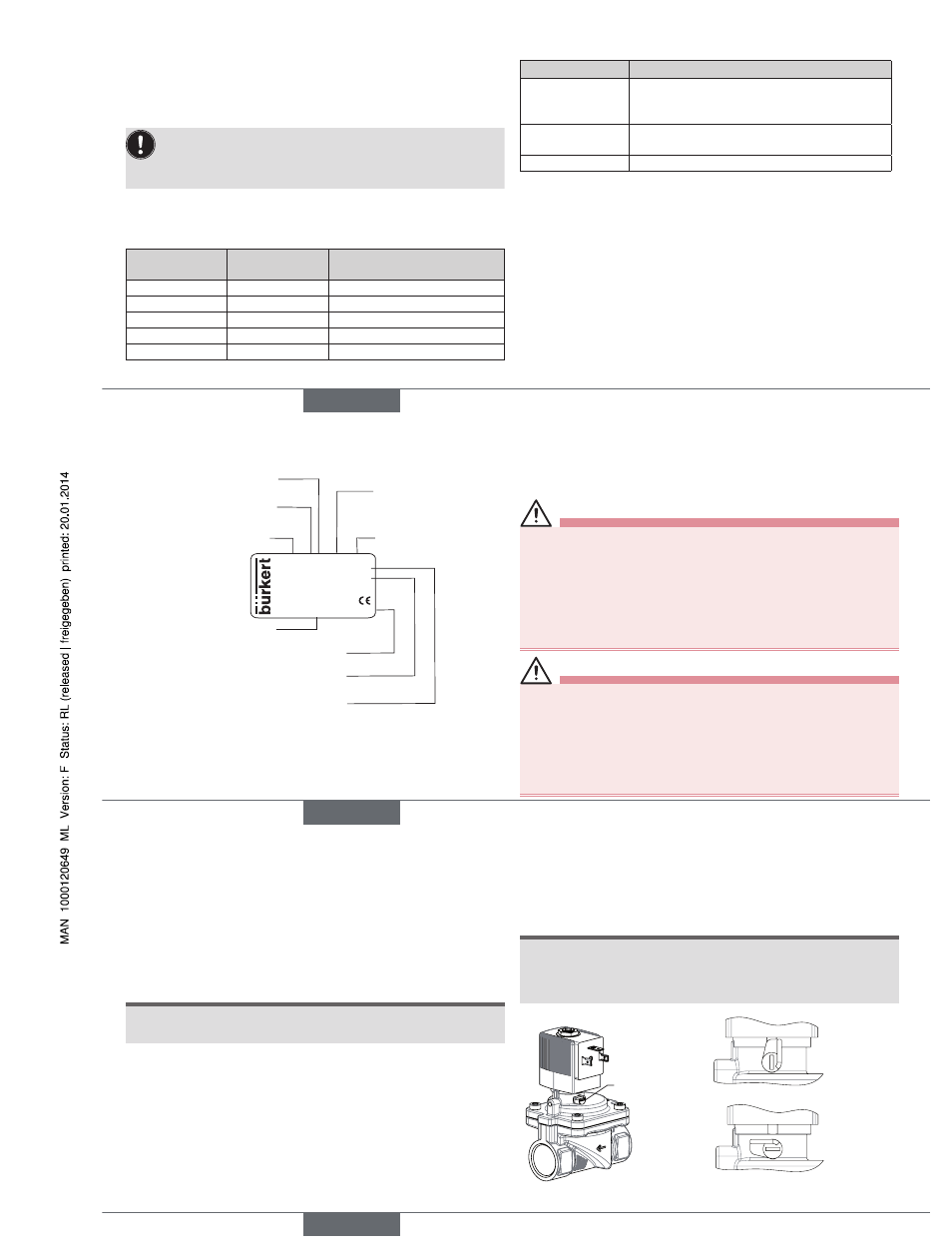

4.5 Type label

Type

Operating

principle

Orifice

Seal material

Body material

Identification number

Manufacturer code

Voltage, Frequency, Power

consumption

Connection thread, Nominal

pressure

6213EV A 10 EPDM MS

Made in Germany

00221649

W14 LU

230V 50Hz 8W

G3/8 P

N0

-

10bar

5

insTallaTiOn

5.1 safety instructions

Danger!

Risk of injury from high pressure in the equipment!

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock!

▶ Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations for

electrical equipment!

Warning!

Risk of injury from improper installation!

▶ Installation may be carried out by authorized technicians only and

with the appropriate tools!

Risk of injury from unintentional activation of the system and an

uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

english

7

5.2 Before installation

Installation position: any, actuator preferably upwards.

Procedure:

→

Check pipelines for dirt and clean.

→

Install a dirt filter before the valve inlet (≤ 500 µm).

5.3 installation

note!

Caution risk of breakage!

• Do not use the coil as a lifting arm.

→

Hold the device with a open-end wrench on the body and screw

into the pipeline.

→

Observe direction of flow:

The arrow on the body indicates the direction of flow.

5.4 Manual emergency actuation

To control the valve manually, the hand lever under the coil must be turned

into the vertical position.

note!

Caution!

▶ Do not overturn hand lever!

▶ When the hand lever is actuated, the valve can no longer be switched

electrically.

Opened position

Closed position

Hand lever

english

Type 6213 EV / 6281 EV