Burkert Type 6211 User Manual

Page 6

20

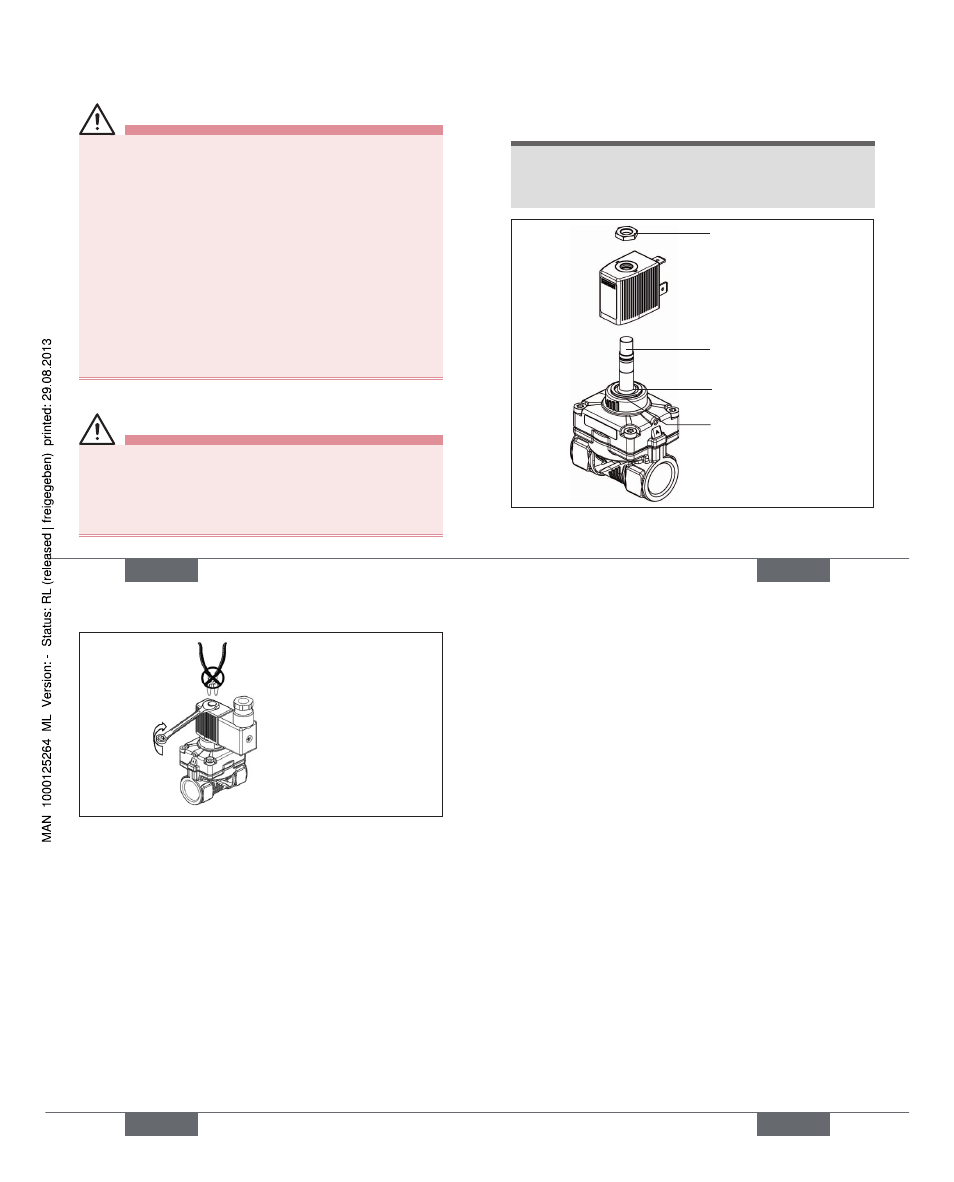

installation of coil

8.2.

Warning!

Escaping medium!

When a sticking nut is loosened, medium may escape.

Do not tighten sticking nut any further.

•

Electric shock!

If the protective conductor is not connected, there is a

risk of electric shock!

Check protective conductor contact after installing the

•

coil.

Overheating, risk of fire!

Connection of the coil without pre-assembled valve will

result in overheating and destroy the coil.

Connect the coil with pre-assembled valve only.

•

Installing the coil:

Warning!

Danger due to electrical shock if coil incorrectly

installed!

During installation ensure that the coil is situated firmly

•

on the housing cover so that the protective conductor

connection of the coil is connected to the valve housing.

english

21

Connect coil housing to the core guide pipe.

→

Screw on coil with nut.

→

note!

Device will be damaged if the wrong tools are used!

Always use a wrench to tighten nut. If other tools are used

(e.g. pliers), the device may be damaged.

Nut

Core guide tube

O-ring

Locking pin

Installing the coil

Fig. 3:

english

22

Torque 2.8 Nm

Torque

Fig. 4:

malfunctions

8.3.

If malfunctions occur, check whether:

the device has been installed according to the

→

instructions,

the electrical and fluid connections are correct,

→

the device is not damaged,

→

all screws have been tightened,

→

the voltage and pressure have been switched on,

→

the pipelines are clean.

→

english

23

Valve does not switch

Possible cause:

Short-circuit or coil interrupted.

•

Core or core area dirty.

•

Medium pressure outside the permitted pressure range.

•

Valve does not close

Possible cause:

Internal space of the valve is dirty.

•

Small control bore in the diaphragm blocked.

•

Diaphragms defective.

•

english

Type 6211 EV