Burkert Type 6012 User Manual

Page 3

7.

installatiOn

7.1. safety instructions

Danger!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock!

• Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations for

electrical equipment!

Warning!

Risk of injury from improper installation!

• Installation may be carried out by authorized technicians only and

with the appropriate tools!

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

• Secure system from unintentional activation.

• Following installation, ensure a controlled restart.

7.2. fluid installation

Danger!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the pressure and

vent the lines.

Installation position: any, actuator preferably upwards.

Procedure:

→

Before installation, clean any possible dirt off the pipelines and

flange connections.

→

If required, install a dirt trap to prevent malfunctions. (Mesh size:

0.2 – 0.4 mm).

Pay attention to the flow direction of the valve!

from 1(P) → 2(A) (CF C) or

from 1(P) → 2(B) (CF D)

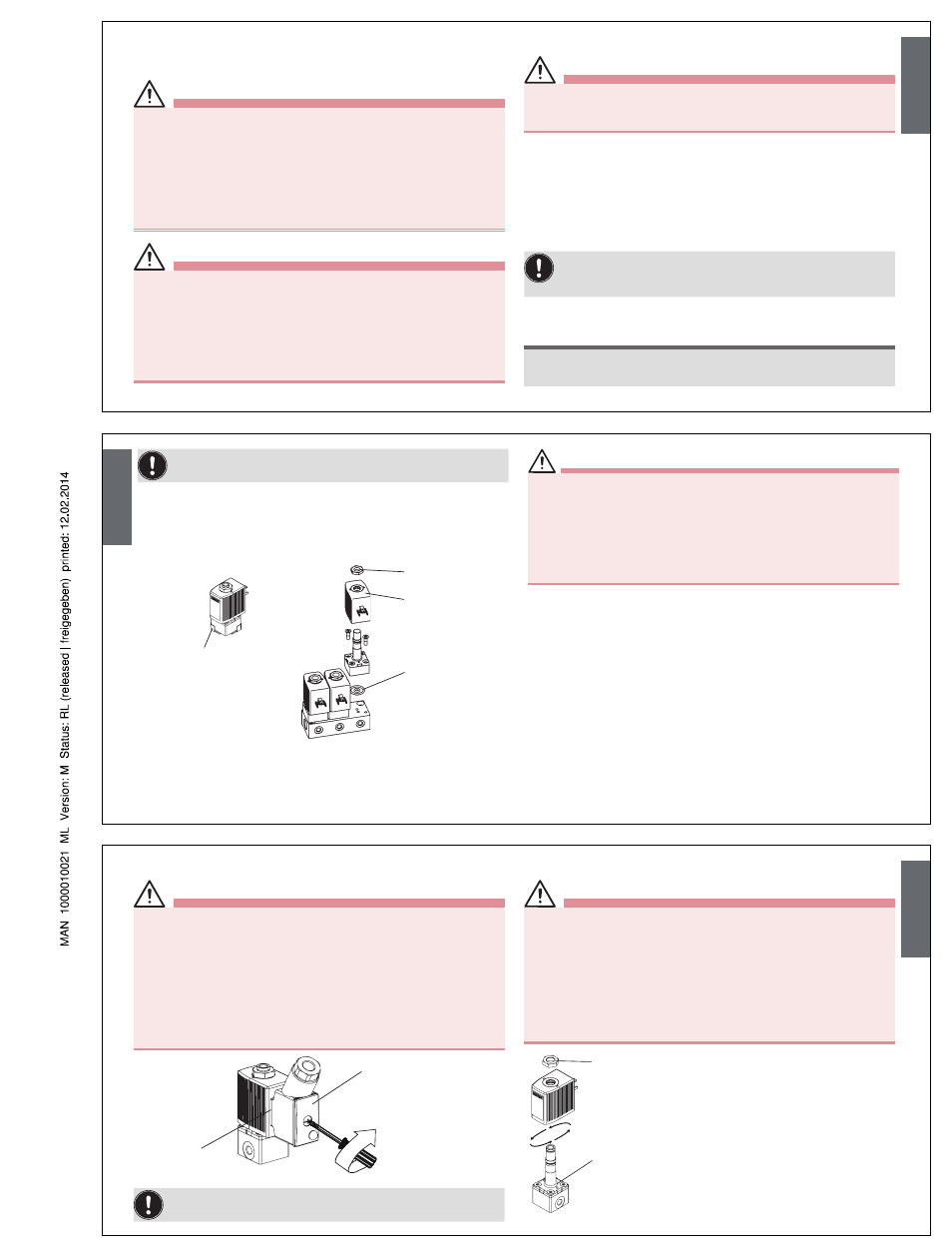

Body with threaded connection:

note!

Caution risk of breakage!

• Do not use the coil as a lifting arm.

english

Use PTFE tape as sealing material.

→

Hold the device with a suitable tool (Open-end wrench) on the

body and screw into the pipeline.

Valve with flanged connection:

Seal

Nut

Coil

Cover plate

→

Remove the cover plate.

→

Loosen the nut on the coil and remove coil.

Warning!

Danger – escaping medium!

Leaking connections if seals not seated properly, if manifold uneven

or if surface quality of the manifold inadequate.

• Make certain the seals included with delivery are properly seated in

the valve.

• Ensure that the manifold is even.

• Ensure that the surface quality of the manifold is adequate.

→

Insert the seal into the valve.

→

Screw the body onto the manifold.

→

Attach the coil and screw on the nut (Tightening torque:

max. 2.8 Nm).

english

7.3. electrical connection of the cable plug

Warning!

Risk of injury due to electrical shock!

• Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations for

electrical equipment!

If the protective conductor contact between the coil and body is

missing, there is danger of electrical shock!

• Always connect protective conductor.

• Check electrical continuity between coil and body.

max. 0.30 Nm

Type 2506

Seal

Note the voltage and current type as specified on the type

label.

7.4. installation of coil

Warning!

Electric shock!

If the protective conductor contact between the coil and body is

missing, there is danger of electrical shock!

• Check protective conductor contact after installing the coil.

Overheating, Risk of fire!

Connection of the coil without pre-assembled valve will result in

overheating and destroy the coil.

• Connect the coil with assembled valve only.

4 x 90°

Nut

max. 2.8 Nm

O-ring

The coil can be turned by 4 x 90°:

→

Loosen nut.

→

Turn coil.

→

Tighten nut with suitable tool

(Open-end wrench) (max. 2.8

Nm).

english