6maintenance, troubleshooting – Burkert Type 5282 User Manual

Page 4

8

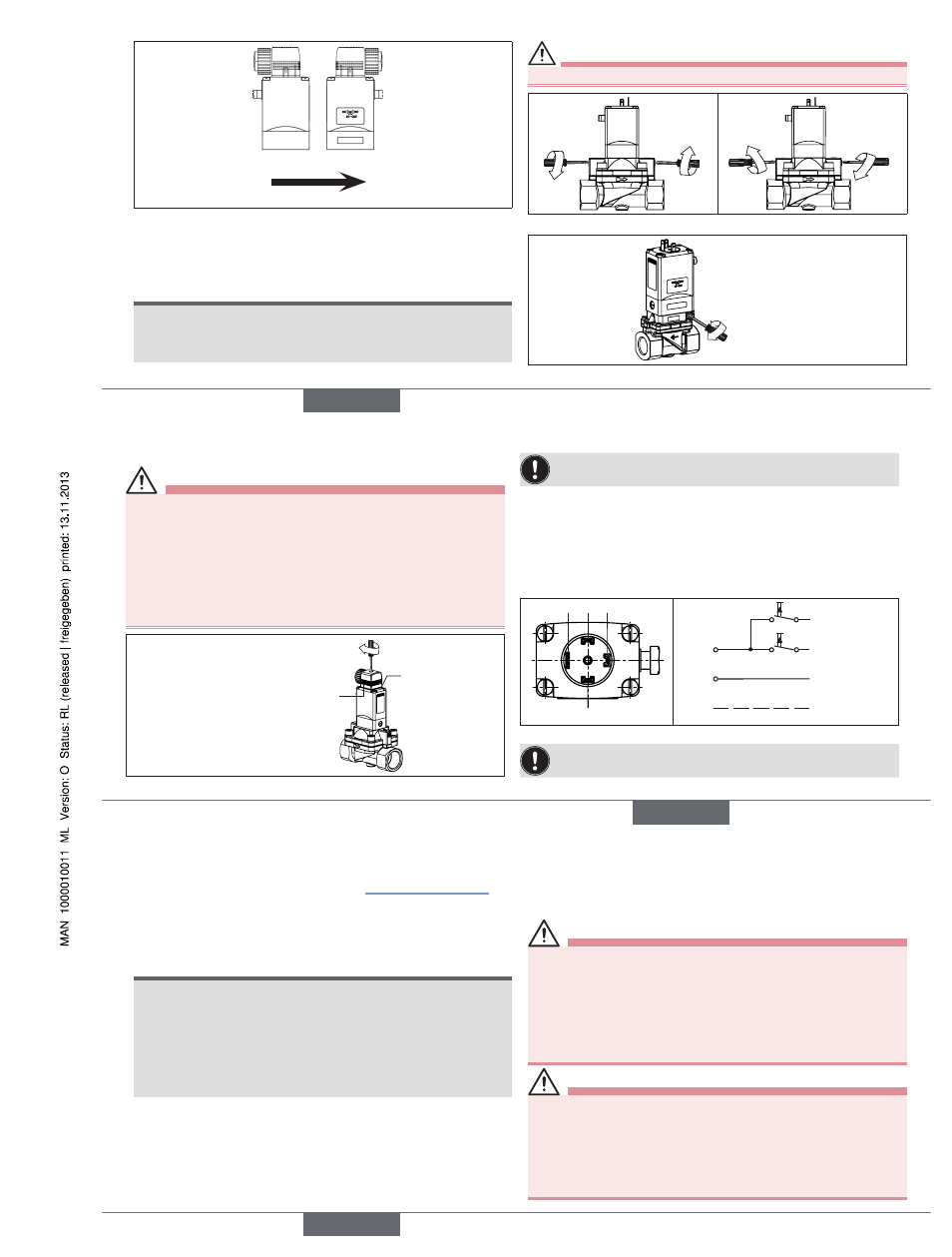

Flow direction

Function NC Function NO

Function NC

The pilot valve is ins-

talled in such a way that

the manual emergency

actuation points in the

direction opposite to

the direction of flow

arrow.

Function NO

The pilot valve is ins-

talled in such a way

that the manual emer-

gency actuation points

in the same direction as

the identification for the

flow direction.

Fig. 4:

Valve functions (NC/NO)

5.6 Setting the switching times

The closing and opening times of the valve can be changed if required with

the side throttle screws.

NOTE!

Pressure surges caused by liquid media and short closing times!

• If closing times are fairly short, liquid media cause higher pressure

surges. These may reduce the service life of the diaphragm and

destroy other devices and components in the system.

CAUTION!

Discharge of medium if the throttle screws are unscrewed too far!

Extending

closing times

Extending

opening times

Reducing

closing times

Reducing

opening times

Fig. 5:

Extending / reducing switching times

Extending / reducing

switching times

Fig. 6:

Extending / reducing switching times for DN13 stainless steel

english

9

5.7 Electrical connection of the cable plug

DANGER!

Risk of injury due to electrical shock!

▶ Before reaching into the device / equipment switch off the power

supply and secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations for

electrical equipment!

If the protective conductor is not connected, there is a risk of electric

shock!

▶ Always connect protective conductor and check electrical continuity

coil and body.

Authorized cable plug e.g.

Type 2508 or other suitable cable

plug in accordance with

DIN EN 175301-803 Form A

max. 1 Nm

Seal

Fig. 7:

Electrical connection of the cable plug

Note the voltage and current type as specified on the type label.

→

Tighten cable plug (for permitted types see data sheet), observing

max. torque 1 Nm.

→

Check that seal is fitted correctly.

→

Connect protective conductor and check electrical continuity between

coil and body.

5.7.1 Electrical connection - Pulse (CF 02)

2

4

3

1

Terminal 1

(

=)

∼

(+) L1

(–) N

PE

Terminal 2

Terminal 3

Earth connector

Fig. 8:

Circuit diagram

The connection terminals in the device socket are identified with

the numbers 1 to 3 according to the terminals on the valve.

english

10

Procedure:

→

Pulse valves (variable code CF 02) as in “Fig. 8: Circuit diagram”

connect. Pulse to Terminal 1 closes the valve; pulse to Terminal 2

opens the valve.

→

Connect standard version L1/+ or N/– to Terminals 1 and 2 irres-

pective of the polarity.

NOTE!

Important information:

• Avoid emitting pulses simultaneously to both coil windings.

• Do not switch any other consumers (relays, etc.) at the same time as

the terminals.

• The coil connection, to which voltage is not applied, must be galva-

nically isolated (open).

• If two or more valves are switched in parallel, ensure that this requi-

rement is met by using 2-pole or multi-pole switches.

6

MAINTENANCE,

TROUBLESHOOTING

6.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

▶ Before loosening the pipes and valves, turn off the pressure and vent

the pipes.

Risk of injury due to electrical shock!

▶ Before reaching into the device or the equipment,

switch off the

power supply and secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations for

electrical equipment!

WARNING!

Risk of injury from improper maintenance!

▶ Maintenance may be carried out by authorized technicians only and

with the appropriate tools!

Risk of injury from unintentional activation of the system and an

uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

english

Type 5282